Protecting Landfill Gas Wellheads and Collection Hoses from Subzero Temperatures

By Eric Nielson and Valerie Nielsen, Q.E.D. Environmental Systems

When the temperatures at a landfill drop well below freezing levels, frozen condensation on wellheads and...

Mechanical Seal Energy Audits and Their Value: Part 1 of 4

Energy Management is critical to operational efficiency. Reviewing energy use in each link of the supply chain of a business can produce significant benefits....

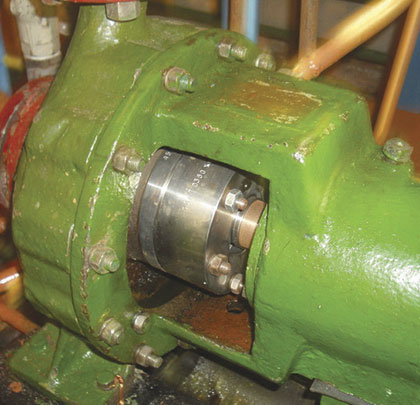

How to Cost-justify Bearing Housing Protector Seals – Part 2 of...

In the first of this four-part article, we pointed out the importance of keeping contaminants away from lube oil in pump bearing housings. We...

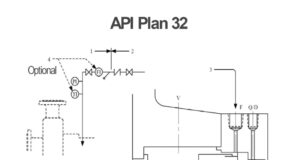

How to Respond to Mechanical Seal Leakage in a Centrifugal Pump

In order to understand centrifugal pump leakage, it’s important to first understand the basic operation of a centrifugal pump. As the flow enters through...

How To Detect Leaks in Your Compressed Air System

By Emily Newton

Unaddressed compressed air leaks can lead to increased costs, equipment malfunctions, and other issues that cause headaches in industrial settings. However, you...

More Demand for Complete System Solutions

Irrespective of industry or sector, manufacturers and plant operators are increasingly choosing to invest in complete system solutions which can easily be integrated into...

The Mechanical Seal Industry’s Contribution to Energy Efficiency in Pumping Systems

By Richard Smith and Chris Booth, AESSeal

See Part 1 Here

In last month’s beginning to this article, we posited that, although sealing devices account for...

Innovative synthetic lubricant tackles extreme conditions in power plant operations

For heavy-duty power generation applications, particularly coal-fired plants relying on large open gear systems, finding a lubricant that can withstand these conditions while also...

The secret to more stable pump operation

An Italian pump manufacturer has ordered Vesconite Hilube line shaft bushings following a successful efficiency test conducted at its pump’s Best Efficiency Point (BEP)....

The New Right Way

Building a successful service business is huge challenge. Focusing on service excellence, creating value for customers and at the same time controlling your costs...