In last month’s installment, we outlined a few of the unforeseen consequences that stem from the decision to single-source reliability-critical components and explained why global single-source procurement strategies for reliability-critical components rarely (if ever) meet a buyer’s overall objectives and expectations. Below, we’ll lay out our suggestions for the roadmap to optimized seal selection, which will include common-sense obligations and responsibilities for equitable owner-manufacturer partnerships as well guidelines for oversight, compensation, and other terms.

OBLIGATIONS AND RESPONSIBILITIES OF THE PARTIES

It was not the intention of this article to suggest or prescribe iron-clad stipulations, obligations, or the exact wording chosen here. Suffice it to say that all mature relationships are anchored in communication, cooperation, and consideration. While specifics can be fine-tuned, these “three Cs” are principles to be upheld. That said, a cooperative owner must communicate the following to the supplier:

- Accurate data on maintenance history and parts consumption of the equipment population covered by the agreement. To the extent it is determined that insufficient history does not allow suppliers to accurately estimate their cost of meeting obligations under the terms set forth in an agreement, the supplier should be allowed an adjustment of the fees to be paid to them, or delete the equipment from the population covered by the agreement.

- Timely implementation of recommended and mutually agreed-to upgrades or improvements necessary to achieve the goals and/or objectives of the agreement. If the improvements are not made in a timely and agreed-upon manner, the same remedies should be available to the supplier as stated above.

- Suitable access to plant and working space is needed.

- Access for training must be granted, at least annually, during normal working hours and at no cost to the supplier. The training should be extended to such operations and maintenance personnel as have a direct impact on the reliability and performance of the equipment covered by the agreement.

- Adequately decontaminated equipment, or the knowledge and facilities allowing the supplier to adequately decontaminate any equipment or device that is to be handled by supplier.

- Material safety data sheets and related documentation.

Payment, net thirty days and with surcharges of 1.5 percent per month of unpaid balance thereafter. - The supplier should provide the products and services covered by this agreement, barring labor strife, catastrophes, shutdowns, etc., in which case equitable pro-rata separation of responsibilities would have to be made.

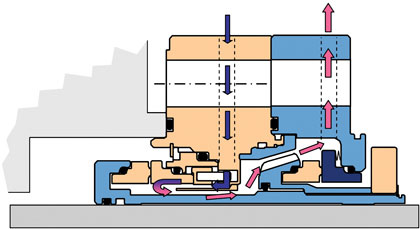

Figure 1: A highly effective tapered, bi-directional, pumping ring (Innovative Vendor).

SUCCESS OVERSIGHT COMMITTEE AND ARBITRATOR

Each party should appoint at least two (but no more than three) individuals to a committee charged with overseeing the timely and successful implementation of the agreement at each plant site. This committee should convene periodically, but no less frequent than every sixty days.

In plants with two or more sites, an executive committee should monitor the overall progress. The committee should have at least one member from each side with sufficient authority to resolve disputes and direct corrective steps to resolve deficiencies in their company’s performance under the terms of this agreement.

Disputes that cannot be resolved by the committee(s) should be submitted to an independent third-party arbitrator who will be designated by mutual agreement at the inception of this agreement and whose fees should be paid equally by both supplier and owner.

COMPENSATION, TERMS AND TERMINATION

The base fee should be set by mutual agreement based on prior yearly seal consumption (equipment MTBR), as well as historic expenditures for such related outlays as seal failure induced collateral damage, production losses, and so on.

In addition, the supplier should earn a mutually agreed-to success fee equivalent to one third of the overall savings generated by the enhancements and to the extent that these exceed the predetermined goals of the program. Savings are defined as direct and measurable savings in labor, parts, energy, incremental production, and so on.

A typical agreement should cover a five-year period, and early termination of the contract without cause will cause monetary damage to both parties. Therefore, the party terminating without cause should agree to pay the other party damages equivalent to twelve months base fee and an annualized success or, as the case may be, non-realized success fee based on the results achieved (or, as the case may be, forfeited) because of early termination.

Of course, the article merely represents a basic proposal for an equitable agreement that serves both parties. While it may not be considered complete, it should form the cornerstone of your partnership agreement with a seal supplier. A number of action steps will be involved in carrying the agreement forward:

- Identify Mechanical Seal Manufacturers A, B, C, and D.

- Provide e-mail with invitation to reply by a deadline date (typically one week).

- Request experience data disclosing seal type and average life attained.

- Request feedback on applicability of gas lubricated seals.

- Provide the four manufacturers with tabulation of data needed for comparison and/or evaluation:

• Materials of construction stationary faces versus rotating faces

• Springs or bellows

• Gaskets or O-rings

• Balance ratios inboard set versus outboard face set - Request manufacturer’s comment on available seal cavity dimension.

- Request feedback on seal cavity modification options.

- Request data from CPRS (highly experienced pump repair shops with full competence in pump upgrading).

- Compare against product flush lost into pumpage (contractor/consultant calculation) to determine incremental savings.

- API Flush Plan Number.

- Heat removal rate of cooler (if a cooler is used).

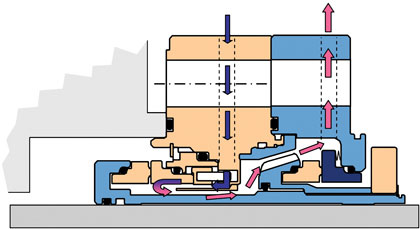

Figure 2: Cog-style pumping rings associated with relatively inefficient flowrate and heat removal capability (Vendor “B”).

THE ROADMAP TO OPTIMIZED SEAL SELECTION

In the final analysis, we believe that structuring mutually beneficial alliance partnerships is possible. Mechanical seals for process pumps rank highest on the list, but other component or services alliances are also feasible. The issue of single-sourcing deserves attention but should not be applied to all conceivable components or subassemblies. A manufacturer of process pumps may well elect to provide—and thus “single-source”—pump shaft, casing, bearing housing, base plate, and so on. In like manner the mechanical seal manufacturer may decide to be the sole provider of all the parts which he then assembles into a mechanical seal cartridge.

At issue for reliability-focused users are technology updates and the grooming or nurturing of future generations of professionals. The needs of these long-range activities will not be met by removing from other competent providers the incentive to participate in presenting best technology. Including one or two presumed second tier (size-wise) seal manufacturers in your plans will be the best possible assurance for a user company to become familiar with innovation and quality of service. These are rarely available from the largest size/largest volume manufacturers—just look at the automobile industry.

Give serious consideration to inviting Vendors “B” through “D” if the opportunity presents itself. Ask them to propose all mechanical seals for a certain add-on project or process unit. Make your plant an 80 / 20 percent plant and reap benefits far in excess of a mere percentage reduction in the cost of mechanical seals originating from a single source. The value of using best available technology and long-term effective training by different innovative parties must be factored-in as we try to list all the benefits of an engineering approach.

And here’s an update on training via lunch-and-learn meetings: That type of training is very much on the decline. Until relatively recently, component manufacturers allocated some of their marketing money for lunch-and-learn sessions at select EPC and user locations. The frequency of such in-office or in-plant sessions has notably lessened wherever global supply agreements are firmly in place. Money spent on lunch-and-learn sessions for the non-empowered and for employees intent only on grabbing a free lunch is considered money wasted. The situation will change only if total received value is shifted toward the positive. A shift in value will be perceived when technology updates are again provided through responsible teaching and mentoring by innovators.

Look back to the first installment of this series. If mechanical seal consumers are unaware with where, when and why the assembly in figure 1 exceeds the value of the assembly in figure 2, Vendor “C” would be pleased to explain. Without having the answers, an owner-user’s exposure to potential cost and risk will be much greater than it needs to be.

About The Author

Heinz P. Bloch, P.E., is one of the world’s most recognized experts in machine reliability and has served as a founding member of the board of the Texas A&M University’s International Pump Users’ Symposium. He is a Life Fellow of the ASME, in addition to having maintained his registration as a Professional Engineer in both New Jersey and Texas for several straight decades. As a consultant, Mr. Bloch is world-renowned and value-adding. He can be contacted at heinzpbloch@gmail.com.

MODERN PUMPING TODAY, March 2015

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!