The Proper Pump, Maintenance, and Air Line Accessories Mitigate Problems Caused...

Pump operators should use filters and regulators when needed to condition the air supply. This encourages more reliable pump performance and reduces equipment wear...

Prevent Expensive Pump Cavitation Damage

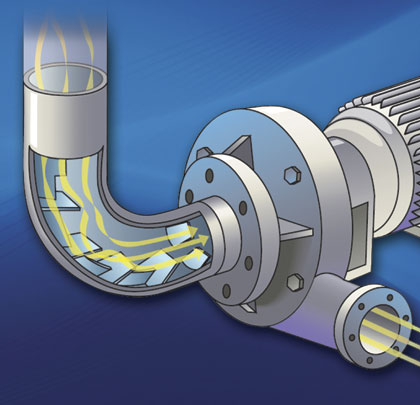

Process engineers responsible for keeping the pumps running in plants crowded with equipment and awkward pipe layouts will find the Vortab Elbow Flow Conditioner...

The Proper Pump, Maintenance, and Air Line Accessories Mitigate Problems Caused...

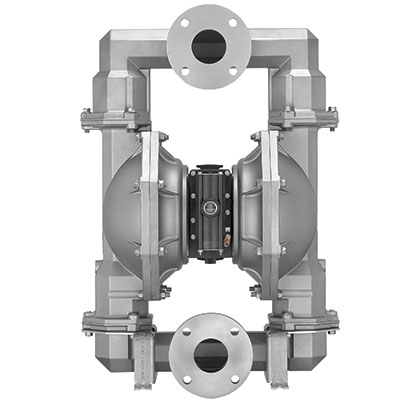

Pumping system operators seeking durable, low-maintenance, easy-to-run equipment for fluid management often look to air-operated diaphragm (AOD) pumps. These pumps can move fluids of...

Meet the New Breed of Thermoplastic Polymer Composites for Pumps

EGC Critical Components, a leading manufacturer of high-performance thermoplastic performance-critical components, today announced its dures™ brand of materials—a new family of proprietary thermoplastic polymer...

Arc Flash Hazards: Are Your Employees Trained?

Previous editions of NFPA 70E required an arc flash hazard analysis. The 2015 edition now requires an arc flash risk assessment to determine if...

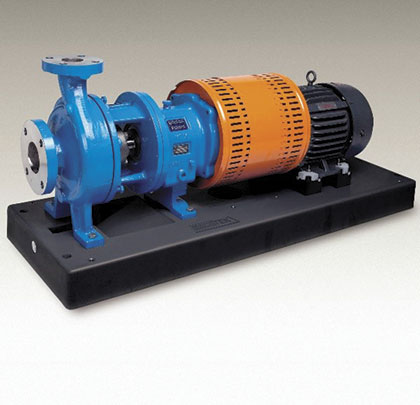

Reliability Starts from the Ground Up

Asolid foundation is a proven way to increase the mean time between planned maintenance for most types of rotating equipment. Pump bases and foundations...

Root Cause Analysis: The Justification Game Part 2 of...

In last month’s introductory article, we discussed some of the barriers to selling not only the concept of Root Cause Analysis (RCA) but also...

Root Cause Analysis: The Justification Game

How often are good ideas turned away because we cannot seem to justify their returns with hard dollars? More often than not, it is...

See the First One-Piece Silicon Carbide Degassing Rotors

The presence of gas—typically hydrogen—and other particles inside gravity or sand castings has the potential to severely compromise both appearance and performance through the...

Curing a Raw Water Pumping Facility’s Unremitting Driveshaft Failures Part 2...

In the first part of this article, a major pump OEMs had invited Mechanical Solutions, Inc. to resolve an occurrence of multiple pump driveshaft...