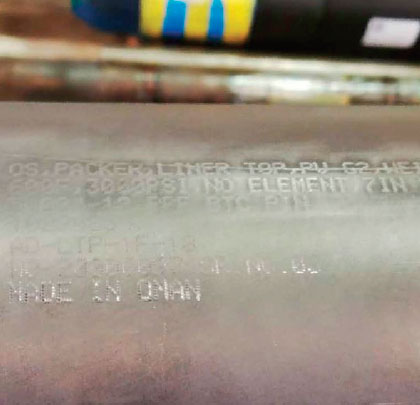

The first thermal Colossus liner hanger systems manufactured in Oman are designed to withstand superheated steam at 600 degrees Fahrenheit (316 degrees Celsius) and prolonged exposure to acid.

In the Sultanate of Oman, Petroleum Development Oman (PDO), accounts for roughly 70 percent of the country’s crude oil production and nearly 100 percent of its natural gas supply. Thanks to a partnership with Schlumberger, the company recently achieved its goal of maximizing local content while acquiring highly specialized equipment to withstand cyclic steam stimulation (CSS).

CHALLENGE

Acquire ten uncemented liner hanger systems rated to 600 degrees Fahrenheit (316 degrees Celsius) and incorporating liner top packers capable of withstanding up to 18 hours of acid treatment before setting.

SOLUTION

Deploy thermal COLOSSUS liner hanger systems manufactured and tested in local Schlumberger facility—a first for Oman.

RESULT

- Saved eight weeks of delivery time for each system

compared with importation. - Increased order by ten additional systems.

- Enhanced in-country value.

LINER HANGER SYSTEM REQUIRED TO WITHSTAND ACID AND STEAM

Petroleum Development Oman (PDO) was planning to use CSS for enhanced oil recovery (EOR) in the Thayfut oil field in southern Oman. During this thermal recovery process (also called steam soak or huff ’n’ puff), steam generated at the surface is injected into the reservoir. The well is subsequently shut in for several days to allow uniform heat distribution to thin the oil. Finally, the thinned oil is produced through the same well. The cycle is repeated as long as the oil production is profitable.

Bids were invited for the supply of liner hanger equipment that could withstand the steam temperature of 600 degrees Fahrenheit (316 degrees Celsius). After setting the liner hanger, the well plan required circulation of acid through an inner string for up to eighteen hours to improve well injectivity. The return path of the acid past the unset liner top packer necessitated a packer capable of withstanding the prolonged exposure.

LOCAL MANUFACTURE PROPOSED TO MEET MULTIPLE OPERATOR GOALS

PDO has traditionally imported liner hanger equipment, but it is keen to advance its strategy of enhancing in-country value (ICV) by increasing the use of local products and services as well as by improving the capability of Omani nationals and companies to manufacture and supply key items.

Schlumberger proposed manufacturing a thermal, uncemented COLOSSUS liner hanger system comprising a hydraulically set pocket-slip (HPS) hanger and a liner top packer at its manufacturing facility in Nizwa, Oman, increasing ICV while reducing both costs and delivery time. Equipped with modern precision machines using computer numerical control, this facility is consistent with Schlumberger’s commitment to a multimillion dollar enhancement in ICV for Oman.

Total commitment and close teamwork enabled efficient delivery of the highly specialized system—the most advanced technology manufactured to date at the Schlumberger facility in Nizwa, Oman.

ADVANCED SYSTEM DELIVERED ON TIME AND ON BUDGET

The proposal was accepted and resulted in doubling of the award to a total of 20 thermal liner hanger systems. Work commenced without delay to meet the 3-month deadline for the first system. Engineering and manufacturing files were developed locally, a dedicated manufacturing and quality engineer assigned, raw materials ordered, specialized equipment sourced, and components manufactured and assembled under expert supervision to form an integrated system, which subsequently passed the stringent Schlumberger qualification process.

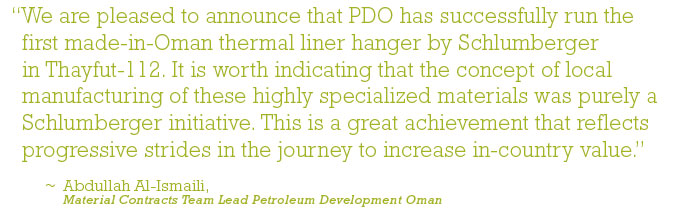

In addition to increasing local content, the operator achieved significant cost savings compared with importation and a reduction of about 8 weeks in delivery time, enabling timely commencement of the drilling phase. All liner hanger system installations to date have been flawlessly executed in accordance with Schlumberger Standard Work Instructions, which maximize successful outcomes. The systems have successfully withstood the extended acid treatments and the superheated steam temperatures in the wells where CSS has commenced, earning formal recognition from PDO and generating considerable interest among other operators in Oman.

ABOUT THE AUTHOR

Guy Arrington is vice president of operational planning and resource management. Schlumberger is the world’s leading provider of technology for reservoir characterization, drilling, production, and processing to the oil and gas industry. Working in more than 85 countries and employing approximately 100,000 people who represent over 140 nationalities, Schlumberger supplies the industry’s most comprehensive range of products and services, from exploration through production and integrated pore-to-pipeline solutions for hydrocarbon recovery that optimize reservoir performance. For more information, visit www.slb.com.

_______________________________________________________

MODERN PUMPING TODAY, July 2018

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!