Equipment Maintenance and Monitoring Best Practices

Pumping machinery is continually subjected to wear and tear and therefore is vulnerable to failure. Correct operation, timely maintenance, and upkeep of pumping station...

Pump Selection Is Just a Click Away

Successfully maintaining a pump system takes countless man-hours and sizeable investment capital. However, one of the most critical steps in ensuring a pump operates...

Lubrication Technology that Can Take the Heat

Across a variety of compressor applications, some things remain constant. Operators are seeking greater efficiency in the face of an increasingly volatile range of...

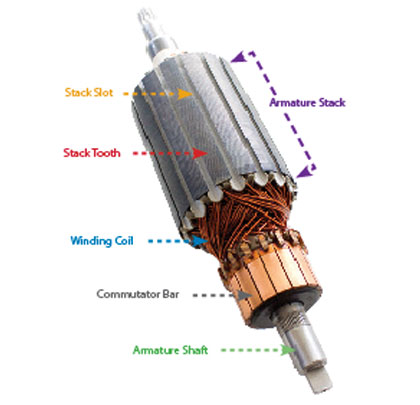

How to Check a Motor Armature for Damaged Windings

If you have access to a volt/ohm meter, there are three quick checks you can do that will tell you if a motor armature...

Pump Rebuild Protection to Help Maximize Pump Life

Pumps are major investments for any company, and the practice of rebuild over replacement not only yields cost savings, but often lessens the amount...

The New Iron Age

Across a range of industries, 3D printing technology is changing what manufacturers, design engineers, and maintenance professionals think is possible. The old cost-benefit analysis...

Torque Density vs. Durability

For a wide range of applications, disc couplings are the best solution to link a drive or other power source to rotating equipment. Even...

Maintenance Is No Surprise Part 2

In part 1 of this article, we discussed that a rotating machine begins to diminish in life immediately upon its first use. Although this...

Maintenance Is No Surprise Part 1

Rotating machinery has an expected life cycle based upon engineered rate of wear due to load, lubricity and speed. Our predominant speed for machinery...

Explaining Unexplained Failures: Breaking the Cycle of Pump Repairs Part 4

Lubricant contamination originates from a number of possible sources and can also be a factor in so-called unexplained repeat failures. As if it requires...