Tanks and the substances they hold are a critical part of many business processes with downtime an unacceptable risk if levels run low or, in the case of waste tanks, capacity is filled. Traditionally, tank monitoring has been an inefficient process involving sending a person to check the level of a tank by visually inspecting the level. Alternatively, loose estimates have been used so trucks have been sent to refill tanks that do not need filling or to empty tanks that are not yet full. This is highly inefficient leading to wasted truck journeys, repeated trips, and keeping money tied up in excess inventory.

SEEKING NEW TECHNOLOGIES

For organizations that utilize tanks for fuel, water, waste liquids, and sector-specific substances such as both fresh and used cooking oil, this inefficiency is being eradicated thanks to Internet of Things enabled tanks that can be monitored remotely. The relatively simple addition of a sensor or multiple sensors for different inputs and a gateway to a tank can allow it to communicate its status in real-time, thereby enabling far greater precision to be applied to refilling and emptying schedules. In addition, the need for physical checks is removed and anxiety about the amount left in a tank is taken away by the ability to provide exact, current data.

These benefits enable organizations to optimize their tank operations to ensure maximized uptime, minimized cost, efficient inventory management, enhanced environmental sustainability, and enhanced safety thanks to minimized supply journeys and manual inspections. In addition, the gateway can be utilized to enable other activities such as sensors that monitor the conditions of the tank both inside and outside to ensure the substance it contains is not being affected by extreme cold, heat or moisture. This is a critical consideration for tanks that store volatile substances such as chemicals or gases and for sensitive materials such as grain or fertilizer.

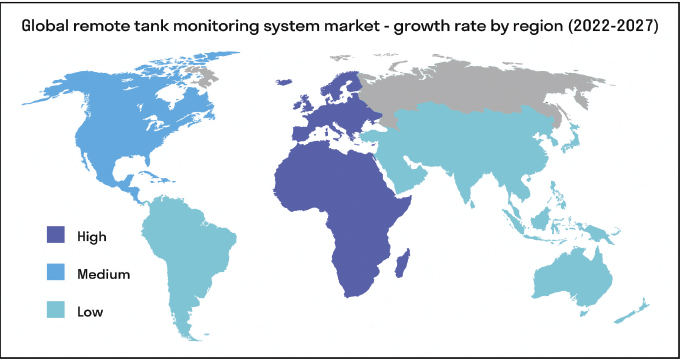

It’s therefore no surprise that remote tank monitoring is a growing and substantial global market. Research firm, Berg Insight, estimates that the global installed base of active remote tanking monitoring systems exceeded 6.2 million units at the end of 2021 and is growing at a compound annual growth rate of 29.9 percent with the firm expecting the active installed base to hit 23 million units in 2026. The North American market leads current adoption with more than 2.6 million active remote tank monitoring units deployed. It is followed by Europe with 1.5 million and the APAC region which has 1.4 million units deployed.

These figures demonstrate a market that is at a relatively early stage. If you consider the sheer number of tanks in the world, a vast volume still need to be connected across industries as diverse as water and wastewater, fuel oil storage, residential oil tanks, propane gas tanks, chemical distribution, liquid fertilizer, groundwater and septic tanks, welding gas distribution, and beverage carbonation. Now, organizations are seeing the value of enabling remote tank monitoring and deploying a variety of solutions to power their systems.

MAKE THE CONNECTION

Although the technology involved in remote tank monitoring is well-established and relatively simple, there are several choices for organizations to make concerning the technologies they adopt. A baseline requirement is to select the sensors that each use case needs to deliver value. Basic examples include a liquid level sensor to report and monitor the amount of the substance left in the tank and these can be augmented with additional sensors to report on heat or moisture and potentially shock or vibration as a means to secure tanks and prevent thefts.

The critical enabler of the “remote” part of remote tank monitoring is the network connection that enables the sensor data to be communicated to the back office. This typically involves installation of a gateway device that contains a wireless module at the tank. Tanks typically utilize cellular networks for wireless communications because they are cost effective, have wide coverage and offer low set up costs. Connecting to a 4G network, for example, requires no wiring and can be a very cost-effective method of delivering the low bandwidth connectivity that tank monitors require. With the ongoing retirements of 2G and 3G networks across the globe, 4G in the form of LTE Cat 1/LTE Cat 1 bis is expected to be the most popular network selection for tank monitoring.

Alternatives include other low power wide area (LPWA) networks, such as narrowband-IoT (NB-IoT). These are dependent on network coverage increasing but they will easily be able to cope with the demands of common remote tank monitoring applications.

The mainstream of the tank monitoring market is well-covered with connectivity options but, away from population centers, further options are needed. Remote mining sites that have large fuel tanks for excavators and other equipment are often in remote locations that are not served by terrestrial cellular networks, for example. Organizations in markets that face coverage issues will need to consider satellite connectivity in the form of non-terrestrial networks (NTN) or other proprietary satellite communications services.

A LOOK AHEAD

In the conclusion of this series, we’ll examine some of the device requirements for bringing accurate date through the gateway as well as the cost benefits remote tank monitoring can provide. To help flesh this idea out, we’ll also look at use case examples reaping these benefits today.

FOR MORE INFORMATION

Quectel’s passion for a smarter world drives us to accelerate IoT innovation. A highly customer-centric organization, we are a global IoT solutions provider backed by outstanding support and services. Our growing global team of 5,900 professionals sets the pace for innovation in cellular, GNSS, Wi-Fi, and Bluetooth modules as well as antennas and services. With regional offices and support across the globe, our international leadership is devoted to advancing IoT and helping build a smarter world. For more information, visit www.quectel.com.

MODERN PUMPING TODAY, May 2024

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!