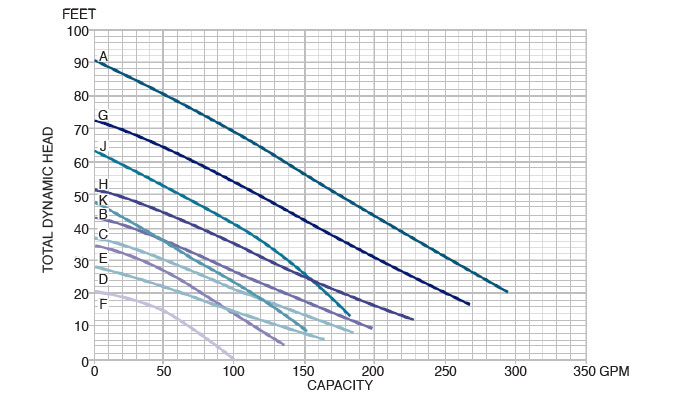

Performance Curve

From self-cleaning toilets to hands-free faucets, new technologies optimize comfort and convenience of everyday life. However, some innovations can expose vulnerabilities in existing systems, thereby prompting the need for improvements and technological advancements to accommodate these modern amenities.

This is the case in the modern wastewater stream. The waste being flushed through the wastewater stream today is very different than in the past, due in part to new consumer products that are entering plumbing systems. As a result, residential wastewater pumps are working overtime to handle these challenges, and new solutions in pump engineering are being developed to help avoid the unintended consequences like clogging and system damage.

Modern wastewater contains a higher amount of synthetic cloth and artificial fibers than ever before. The vast array of disposable cleaning products and personal hygiene products like “flushable” wipes available on the market are to blame. Although these products should be disposed of in the trash, many consumers instead flush them down the toilet, thus adding harmful fibrous material to the wastewater stream.

Despite their ease of use factor, these modern conveniences can come at a high cost considering the detrimental effects these products can have on plumbing systems. Unlike toilet paper, wipes don’t disintegrate easily or quickly and can clog sewage treatment equipment and home septic systems. Clogging can occur when a number of wipes get stuck in the pump, or if debris builds up on the flushable wipes that are already stuck in the system.

Buildup of fats, cooking oil and grease present another significant challenge for residential and municipal wastewater pumping stations. Accumulations of these substances can clog the impeller, reducing pump efficiency or causing pump blockage, which can result in operational problems and the need for costly repair. Obstruction by grease in particular is one of the most prevalent causes of force main backups and sewage overflows, costing the wastewater industry billions of dollars annually.

Current pump technologies commonly used to address modern wastewater challenges and help avoid system damage include grinder pumps and vortex impellers.

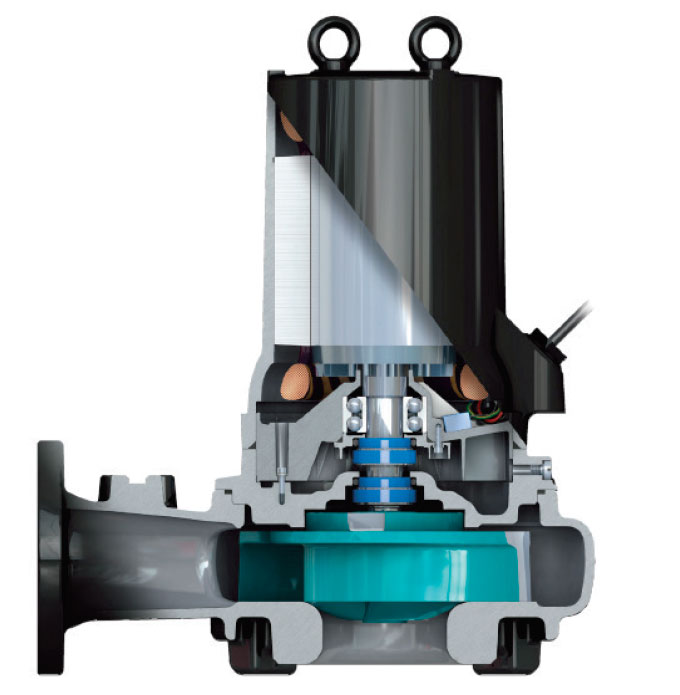

The GFK submersible sewage pump has been proven dependable in efficiency and waste-handling capabilities through extensive field testing.

GRINDER PUMPS

Installing a grinder pump is a standard solution to handle pump clogs and sewer obstructions caused by wipes and other hygiene products that get flushed down the toilet.

A grinder pump is a wastewater transportation device that helps reduce solids to fine slurry so it can be pumped through small-diameter pipes. Many grinder pumps are designed for residential and commercial sewers where flushable wipes are present in the stream. Flushable wipes can go through toilet plumbing, but not necessarily the entire sewage system. This is where a grinder pump takes over. Outfitted with steel blades, the grinder pump cuts solids found in sewage into tiny pieces, which are then passed down the piping network before being discharged at a collection point. Residential grinder pumps are designed for continuous use and are capable of grinding domestic sewage in high head sewage applications.

While grinder pumps are a good choice if solids like flushable wipes are present in the wastewater stream, it is important to understand that these pump installations still need to follow the rules of pump hydraulics. For example, a minimum scouring velocity needs to be maintained so solids are not permitted to settle down, which can cause issues farther down the sewage line.

VORTEX IMPELLERS

Vortex impellers are designed so the wastewater stream material traveling through the impeller does not need to touch it in order to pass. This helps to prevent cloth-like materials from collecting on the impeller and eventually clogging the system.

The design of a vortex impeller pump is such that the impeller is completely recessed within the pump casing, minimizing contact with the process fluid. The impeller creates a whirlpool of pressure that pulls solids through the system without touching the vanes of the impeller, providing free flow-through passage of solids and liquids. If the waste material traveling through the pump is stringy, stranded or even cloth-like, a vortex impeller helps prevent the slurry from forming a twisted mess that would otherwise bind or clog the pump.

Although the vortex impeller pump is a popular choice for demanding residential wastewater applications, the vortex impeller design is not without its drawbacks. The vortex impeller is recessed and not in the primary waste flow path, making its solids-handling ability one of the best in the industry, but also one that results in lower efficiency.

Despite the practice of back flushing—a process where the pump is run backwards to clean the leading edges of the impeller and push the accumulated solids through the pump’s suction opening back into the pump sump, these solids return during normal operation, leading to decreased efficiency and potentially higher energy bills.

MODERN PUMP HYDRAULIC DESIGN

Today there are better, more advanced hydraulic designs available to increase a residential wastewater pump’s clog resistance and maintain pump efficiency over time. A state-of-the-art self-cleaning design, with substantially backswept leading edges and a relief groove, is proving to be the answer to most clogging problems.

Recently, Goulds Water Technology introduced its patented K-impeller technology—a unique anti-clog impeller design for residential wastewater pumps that significantly reduces maintenance and energy costs.

Key to the K-impeller design is the dynamic interaction of the extreme back-swept impeller vanes and the stationary relief groove in the volute suction where the leading edge of each impeller vane is cleaned during pump rotation. The reliability of the K-impeller can be attributed to the semi-open, screw-shaped impeller that prevents clogging and facilitates the unobstructed flow of fibrous material. The leading edge of the pump’s rotating impeller passes across a stationary relief groove located in the pump suction port. The dynamic action cleans and pumps away any rags, stringy materials and solids from the impeller without compromising the hydraulic efficiency.

The self-cleaning impeller design greatly reduces the risk of clogging and makes the K-impeller pump a practical solution for residential applications. Unlike standard residential wastewater pumps, a pump with self-cleaning hydraulics will not accumulate the solid objects that are more likely to be found in modern wastewater.

The K-impeller’s increased clog resistance results in lower power consumption, which in turn improves overall reliability and energy efficiency.

The design of the self-cleaning K-impeller has been proven to reduce clogging and maintain efficiency when pumping wastewater.

SMART TECHNOLOGIES

In addition to newer non-clog technology, smart monitoring technologies are being incorporated into today’s wastewater pumps. Monitoring equipment that detects common threats against wastewater pumps like overheating and seal leaks or failure provide peace of mind through real-time status of the wastewater pump system, sending alerts when maintenance is required.

While dual seal design and sensors for high temperature and seal leak detection come standard on pumps with K-impeller technology like the Goulds Water Technology GFK Series Submersible Sewage Pump, homeowners can right size the pump installation and opt out of connecting the smart pump controls, which are more commonly used in commercial applications.

With the challenges of modern wastewater pumping growing more complex, residential and commercial wastewater pump technology must keep pace. Pump maintenance and replacement can be expensive, which increases the cost of investment, so residential wastewater pumps with non-clog technology that minimize maintenance and decrease downtime are fast becoming the preferred choice.

FOR MORE INFORMATION

Goulds Water Technology is one of Xylem’s global brands that have served the market for several decades. Xylem brands meet the world’s most critical water challenges by engineering a broad portfolio of products, applications and services to create efficient systems and sustainable solutions. For more information, visit www.goulds.com.

_______________________________________________________

MODERN PUMPING TODAY, August 2018

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!