By Simla Ay, Hernon Manufacturing

Hernon Manufacturing, Inc. produces high performance adhesives, sealants, UV LED curing lights, and precision dispensing systems. Headquartered in Sanford, Florida, the company maintains an ever-expanding network of over 100 distributor and partner locations around the globe. Already shipping to over sixty nations, Hernon can provide adhesive solutions to manufacturing operations anywhere in the world. In a recent case study, one of the largest and best-known manufacturers of variable speed water pumping systems in the United States, QuantumFlo, was facing leakage issues during final tests.

THE PROBLEM

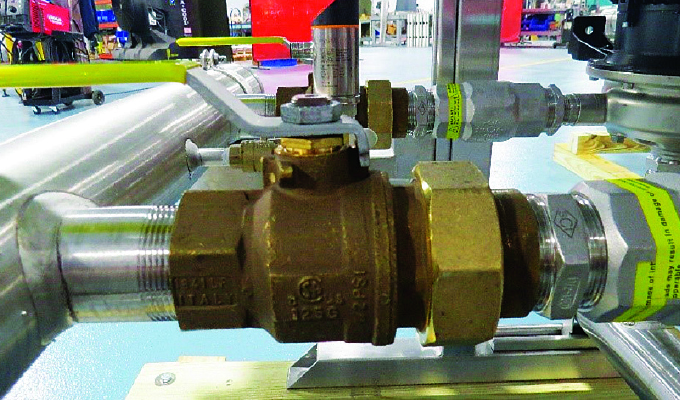

Only 75 percent of finished systems were passing hydro pressure tests for final inspection. Failing systems would be sent back to production stages to be resealed resulting in loss of time and money to re-work. Originally, QuantumFlo was applying coatings of pipe sealant on threaded fittings and adding teflon tape followed by more sealant. This process was time consuming, messy, and failed to meet QuantumFlo’s high quality standards.

THE SOLUTION

QuantumFlo received a sample of Hernon’s Dripstop 940 pipe thread sealant which they applied to their threaded fittings between stainless steel and bronze substrates. Dripstop 940 is specifically formulated to react to metal ions and cures quickly at the exclusion of oxygen for an instant seal. After applying Hernon’s Dripstop 940, QuantumFlo saw an immediate improvement in quality results and after fully adopting Dripstop 940, their finished systems now pass the hydro pressure test at a rate of 98 percent. By using Hernon’s Dripstop 940 only, they saved time, energy, and money.

“We were pleasantly surprised when Hernon technicians directed us to use only a small amount of their Dripstop 940. We were able to significantly reduce the amount of sealant we applied to our fittings and still saw a massive gain in quality,” says David Carrier, president and CEO, QuantumFlo.

“With nearly 100 years of combined industry experience, QuantumFlo is a pioneer of variable speed pumping technology and we have become the standard of the plumbing industry worldwide. We don’t compromise on quality which is why we are so pleased to be using Hernon’s Dripstop 940.”

CLIENT CLOSE-UP

QuantumFlo

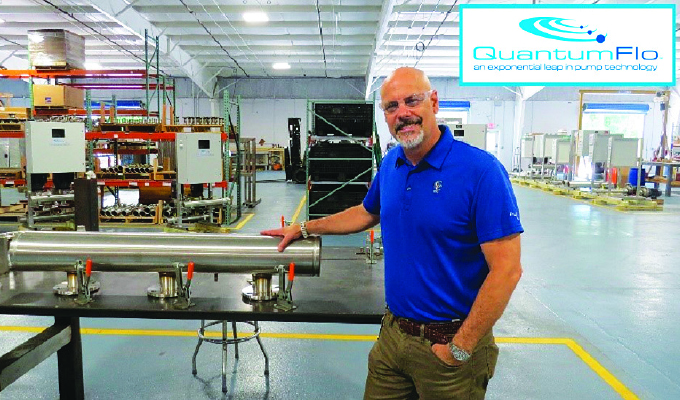

Founded in 2007, QuantumFlo is housed in a state-of-the-art, 30,000 square foot manufacturing facility in Sanford, Florida, just north of the Greater Orlando area. QuantumFlo’s systems are assembled and flow tested in an on-site test lab that features a UL508A industrial custom control panel facility and a large production shop.

QuantumFlo began as a result of the efforts of a determined team of professionals committed to redefining the packaged pump systems market. From perfecting classic designs to the innovation of new products, QuantumFlo has applied creativity and out-of-the-box thinking to develop the quality and integrity of the systems it produces today.

FOR MORE INFORMATION

Hernon Manufacturing maintains a library of over 5,000 unique adhesive and sealant formulas in addition to creating customized formulas to address specific manufacturing challenges. A full in-house chemical laboratory ensures quick turn around on testing and development projects and an on-site machine division allows Hernon to build, service, and integrate unique dispensing systems to even the most exacting specifications. This horizontal integration helps Hernon to provide customers with a Total Solution for any unique application. For more information, visit www.hernon.com.

MODERN PUMPING TODAY, December 2019

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!