Whether it’s at product launches, factory tours, or trade shows, the staff at MPT is afforded an up-close look at the newest offerings for our industry, and each December, we look back on the year that was and present our choices for the Top Products spanning the industrial pump and rotary equipment markets.

In the pages that follow, MPT shares its selections for the products that speak to the industry’s needs for efficiency, reliability, and innovation. Each of our Top Products was chosen through submissions from our staff, advertisers, and readers like you. The products range from large multinationals you’re likely familiar with to smaller, regional suppliers worthy of your attention.

Regardless of their size or reputation, they all offer value you can take into the new year. Enjoy!

AUTOMATIONDIRECT

ProSense Vibration Fork Liquid Level Switches

ProSense® VFL Series Vibration Fork Level Switches from AutomationDirect are designed using tuning fork technology for reliable liquid point level detection for monitoring, alarming, and control applications. The switch tuning forks vibrate at their natural frequency. When the forks contact a liquid, the fork vibration frequency changes and triggers the switch output.

Suitable for use in tanks, vessels, and pipes, the VFL series is an ideal alternative for applications where other liquid point level technologies such as float switches or conductive, optical, and capacitance sensors are not suitable due to conductivity, turbulence, buildup, air bubbles, foam, pressure, temperature, and viscosity changes.

ProSense VFL series switches are offered in two process connection sizes with short and extended insertion lengths, standard and high temperature constructions, and a three-wire DC switch output for connection to controller inputs or a two-wire AC/DC switch for control of valves and pumps. Fork Level Switches start at $137.

For more information, visit www.automationdirect.com/fork-liquid-level.

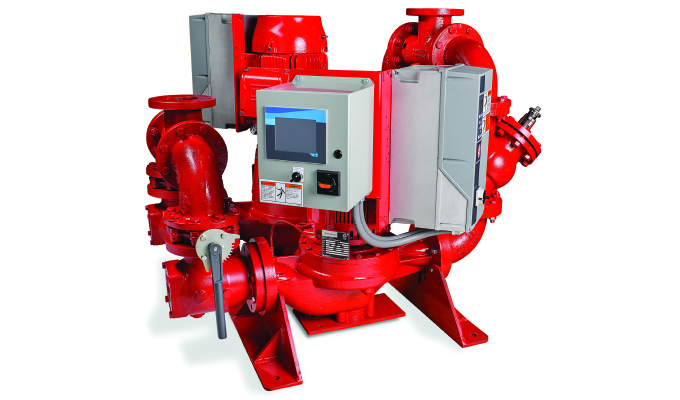

BELL & GOSSETT

Parallel Sensorless Pump

Xylem Inc.’s Bell & Gossett brand is introducing its Parallel Sensorless Controller, a device that provides advanced system staging of up to eight pumps in parallel configuration to maximize system efficiency—an industry-leading offering with a large 5.7-inch touch screen that displays real-time feedback and enables energy modeling.

Sensorless pump control technology relies on pump-specific algorithms, which can accurately predict where a pump operates on its curve. Using speed, torque and power data to know where the pump operates on the curve, sensorless pump controllers can be set up to take action based on those factors.

The staging and destaging multi-pump configurations that are compatible with the Parallel Sensorless Controller are created on the basis of efficiency, thus allowing optimized hydraulic efficiency. It meets ASHRAE 90.1 system efficiency requirements and features advanced system staging with B&G’s expansive Efficiency Island operating range.

With the capability to run parallel configurations with up to eight pumps, B&G’s Parallel Sensorless Controller delivers the best efficiency staging to minimize energy costs and enables individual pumps to take control if one or more units or sensors are not active, ensuring reliable system flow and pressure.

For more information, visit www.bellgossett.com.

BLACOH FLUID CONTROL

SPILLSTOP Pneumatic Version

Being prepared for a system failure or spill is critical. The fully pneumatic SPILLSTOP system safely captures leaked product and automatically shuts down failed pumps to eliminate costly product loss and prevent hazardous spills. Optional warning alarm and backup pump switchover further minimize system downtime for maximum productivity. This unique design is customizable to different material

Unmonitored spills are very costly considering the expense of product loss, system downtime, hazardous cleanup and EPA reporting. By preventing a single spill, the product savings alone would more than pay for your investment in SPILLSTOP.

To increase effectiveness, equip your SPILLSTOP with an optional warning alarm whistle, backup switch, and additional pump shutoff valves for multiple pumps or high suction tank applications.

For more information, visit www.blacoh.com.

CRANE PUMPS & SYSTEMS

Blade NGV and XGV Grinder Pumps by Barnes

The next generation of grinder is here!

Crane Pumps & Systems, a Crane Co. Company, announces an extension of the Blade grinder pump line to include explosion proof (XGV) and non-explosion proof (NGV) options. Backed by the dependability and longevity of the Barnes reputation in submersible pumping, Blade grinder pumps are the Barnes solution to high head wastewater grinding applications in commercial and municipal environments.

Blade grinder pumps are available in 3-, 5-, 7.5-, 10- and 15-horsepower explosion-proof models with 2-, 2.5-, and 3-inch discharge sizes. Blade NGV and XGV grinder pumps were designed with the following valuable features and benefits:

- Plug-and-play cord simplifies pump installation with its quick disconnect capability

- Oil-filled motor for optimal motor cooling and maximum bearing life

- Stainless steel hardware provides resistance against corrosion to extend pump life

- Moisture detection probe alerts pending seal issues before water can enter the motor

- Vortex impeller design greatly reduces clogging issues due to troublesome objects

- Exclusive Slicerator™ slices with the full torque of the motor acting on a small area to provide the ultimate solution in solids reduction

- Available in vertical or horizontal discharge (18 frame only) for simple installation and replacement

- Double mechanical seals provide maximum motor protection

- Heavy duty, oil-lubricated bearings extend pump life

- Large lifting bail allows for easy installation

Efficient operation of the Barnes Slicerator™ radial cutting technology reduces torque required to process solids. The cutter uses hardened stainless steel cutting blades in a staggered position against a cutting ring. This unique design prevents clogging due to particularly troublesome solids like plastics, strings, ropes, sanitary napkins, disposable diapers, and cloth materials.

Like most of the Barnes product line, NGV and XGV grinder pumps are manufactured in the United States. Crane Pumps designs, engineers, and manufactures products domestically in the small town of Piqua, Ohio. Crane has been a part of the Piqua community since 1965, providing job opportunities and philanthropic service to the surrounding area. With engineering, operations, customer service, and sales under the same roof, Crane Pumps is able to control the quality of their products and quickly and effectively service their customers.

For more information, visit www.cranepumps.com.

GAS CLIP TECHNOLOGIES

Multi Gas Clip Simple Plus

Introducing Multi Gas Clip Simple Plus, a new portable four-gas detector with three-year continuous run time. Once activated, this unique multi-gas detector is warranted to provide rapid gas detection 24/7 for three full years. Just turn it on and it’s good to go. Gone are the days of charging your multigas detector every day. This detector never needs charging. Continual calibration is not necessary either. Battery and sensors last the life of the detector. It even detects in oxygen-depleted or oxygen-enriched environments. Reliably test for hydrogen sulfide (H2S), carbon monoxide (CO), oxygen (O2) and combustible gases (LEL) with this simple-to-use and simple-to-maintain detector.

Audible, visual, and vibrating alarms alert instantly when the gas level you set is detected. From the moment gas is detected, until it is no longer present, data is stored on the detector in one second intervals providing the full picture of an event. Bump tests and calibrations are also stored. Full access to this needed information is available to your management team using a laptop or computer and a GCT IR Link or MGC Simple Dock. Data is automatically formulated on a simple-to-read Excel spreadsheet, which saves you the unnecessary expense of outside record maintenance.

What makes this ultra-durable detector able to perform this well for this long even under the harshest of conditions? The secret is the sensor technology. The MGC Simple Plus uses energy-efficient Infrared Sensor Technology inside the LEL combustible gas sensor. Gas is detected with an infrared beam of light which doesn’t require the presence of oxygen and doesn’t rapidly drain the battery enabling the battery to last for years instead of hours. The infrared LEL sensor is immune to sensor poisons eliminating the need to regularly calibrate to offset signal loss. The sensor won’t burst if suddenly exposed to high gas levels and it doesn’t contain fragile parts that can easily break. Operation is fail-safe. All these features add up to a durable and dependable detector that lasts for years and years.

Gas Clip Technologies’ continued development and refinement of advanced low-power photometric infrared technology for LEL measurement found in this newest member of their gas detector family makes gas detection simpler and safer than ever! Detectors are available through distributors worldwide.

For more information, call 972.775.7577 or 877.525.0808, email info@gascliptech.com, or visit www.gascliptech.com.

PUMPS 2000

High Volume Pneumatic Diaphragm Pumps

Pumps 2000, the world leading innovator of diaphragm pumps, introduces the world’s first high-volume (HV) pumps. The 3-inch HV ball valve pump can deliver flow rates up to 416 gallons per minute and pass up to 1.3-inch solids. The 4-inch slurry valve pump delivers flow rates up to 540 gallons per minute and pass 3-inch solids. The high-volume pump series give the user the flexibility in applications where traditionally the only option was electrically driven pumps with the same flow capacities or solid handling capabilities. Pumps 2000 high volume AODD pumps are suitable for pumping applications in all industries and gives the user an alternative in using air pumps to achieve desired flows and slurry handling capabilities that could previously only be obtained with electrically driven pumps.

Pumps 2000 is a superior brand of diaphragm pumps that out-perform and outlast all others. It is the first redesign of the diaphragm pump specifically designed for abrasive, solid-laden, and corrosive fluids in mining and industrial environments. The use of engineered, injected molded plastics gives us greater freedom in material composition and has led to the development of lubrication-free pumps and our own plastic blends. This has created an alternative to other heavy and maintenance-intensive diaphragm pumps. You will find greater flow, larger solids handling, lower air consumption, lower noise levels, and reduced weight but the most important aspects are the reliability, performance and longer maintenance free life.

Pumps 2000 patented features make it possible to offer market-leading low life‑cycle cost and energy savings while delivering outstanding performance in the harshest environments and most difficult applications. Our unique combination of in-house R&D and manufacturing enables us to offer pumps that are technically superior and of significantly higher quality than those offered by competitors.

- Patented double‑hinged diaphragms eliminate the stress on the diaphragm when it flexes, which significantly increases the life over other brands.

- Patented self-cleaning and larger solids handling ball valve and slurry valve design eliminates the problems that plague other brands.

- Patented longer lasting modular air motor components with self-lubricating wear resistant plastics that are non-stalling / freezing and less sensitive to grit / debris in the air lines.

- Patented main seal that eliminates the need to replace the shaft.

- Reduced CFM requirement resulting in lower energy costs.

- Lightweight design reduces neck and back injuries.

- Lower noise levels (below 84 db).

For more information, visit www.pumps2000.com and www.pumps2000america.com.

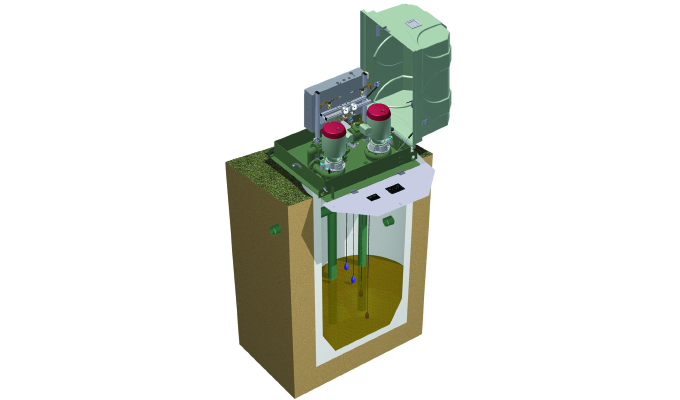

SMITH & LOVELESS

EVERLAST® Wet Well Mounted Pump Stations

Smith & Loveless above-ground EVERLAST® Wet Well Mounted Pump Stations strike the perfect balance between cost-effectiveness, reliability, and operational efficiency for municipalities, private developments, and businesses transferring small- to medium-sized flows of wastewater.

With all pumping equipment, valves, and controls immediately accessible at ground level, these systems are more convenient and cost-effective to operate than traditional submersible pumps. These packaged stations arrive pre-assembled with all equipment installed on a common base and a quick-access enclosure, allowing quick and easy installation on the wet well after basic suction pipe and electrical connections were completed.

Immediate and safe ground-level access to the pumping equipment means these systems significantly reduce the time and personnel required to perform regular O&M. Confined space entry and associated requirements are virtually eliminated, including permitting, harnesses, gas monitoring equipment, and other OSHA and Class 1 Division 1 requirements.

Routine tasks like pulling a pump to change a seal or impeller can be completed in minutes by a single operator, without the use of outside contractors or pricey pump maintenance centers. This contributes significantly to lower S&L EVERLAST® parts and O&M costs when compared to submersibles—documented as much as 50-plus percent—and long service life.

Naturally, operating a pumping system above the liquid level requires priming assistance. There are a variety of ways this can be achieved—including via liquid or compressed air assistance—but S&L’s EVERLAST® sets itself apart from other “self-primers” with a proprietary vacuum-priming system that is more energy-efficient, safe, and serviceable.

For more information, visit www.smithandloveless.com.

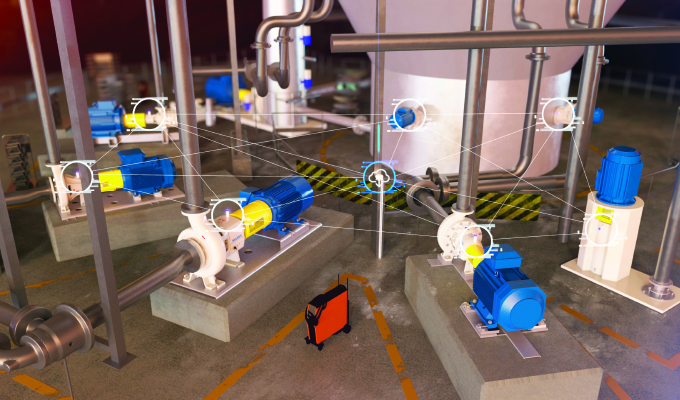

SULZER

Sulzer Sense: Sulzer introduces wireless condition monitoring

Sulzer takes its expertise in pumping solutions to the next level by introducing the Sulzer Sense wireless IoT condition monitoring system. Sulzer’s long experience in demanding industrial processes ensures that the Sulzer Sense monitoring device is built for real-life needs and conditions, to the benefit of our customers.

The solution includes wireless sensors that are attached to a pump, agitator, motor or any rotating equipment. The sensors measure temperature and vibration and send the data to the cloud. This means that the operating status of the equipment can be remotely monitored twenty-four hours a day, seven days a week. Sulzer Sense devices are battery powered and they operate in a wireless mesh network, making them easy and cost-efficient to deploy and operate.

The condition monitoring feature identifies changes in condition parameters and indicates potential faults at an early stage. The new Sulzer Sense monitoring device will detect possible imbalance, misalignment, looseness, and bearing wear. This supports predictive maintenance and helps to avoid sudden pump failure and eventual downtime.

The Sense data is sent to the cloud and can be monitored in Sulzer’s online service on a mobile, tablet, laptop, etc. anywhere and anytime. The customer can set an alert value and will automatically be alarmed if this value is exceeded. No manual measurement is required.

The cloud-based platform is easy to use and offers various value-adding services. The customers have secure access to the latest equipment data and related services, including documentation and condition monitoring values.

Sulzer Sense increases the productivity and efficiency at the site. It takes care of the process equipment in an easy, safe, and convenient way.

For more information, visit www.sulzer.com/sulzersense.

VAUGHAN COMPANY

Conditioning Pump

One of the most common problems lift stations/collection pits encounter is how to eliminate floating grease mats. If left unattended, the layer will continue to thicken until, eventually, a vacuum truck is required to suck out the mat. Over time, the frequent vacuum truck calls can result in thousands of dollars of maintenance and dumping fees. Alternatively, the proper solids-handling pump system can bypass the frequent service calls and contribute to a more cost-efficient lift station.

While most pumps in today’s market will effectively pump fluid, inputting the variable of debris, thickened sludge, and other solids into the mix drastically hinders the ability of those pumps to do their job. Furthermore, unclogging those pumps can be expensive and some pumps can even cost upward of $350,000 to replace if they clog beyond repair. The Conditioning Pump was created to help resolve this problem at a fraction of the cost.

A Conditioning Pump is a submersible chopper pump that is designed by Vaughan Company to be used in several different scenarios to save on costly clean out cycles and maintenance. Conditioning pumps are mounted on a portable stand and fitted with a high-velocity mixing nozzle to recirculate the contents of a wet well. The Conditioning Pump can be placed directly in the wet well to chew up all of the rags and solids so that the existing pump won’t get clogged. Floating mats are removed and solids that have accumulated on the floor are re-suspended. As the pump is mounted on a portable stand it can easily be used in multiple applications at a single job-site, facility, or municipality.

Recently, the Otay River Pump Station (ORPS) in San Diego, California, had a problem in the large 50-feet long x 10-feet wide x 30-feet deep wet well. A floating blanket of grease and debris, sometimes as thick as 4 feet, would occur on a regular basis. The City of San Diego had been contracting two vacuum trucks to clean out the station every three to four months at a cost of approximately $50,000-$100,000 per year. As the city previously had a good experience with Vaughan Chopper pumps, they turned once again to Vaughan Company for a more cost-effective solution.

For ORPS, an 8-inch Submersible Chopper Pump with a 25 horsepower, 1,200 rpm motor, mixing nozzle, and portable stand. In eighteen months of use with the Vaughan Conditioning pump, the wet well has not required cleaning. Based on the cost of the pump and installation the pump paid for itself in two and a half months of use.

For more information on Conditioning Pumps, visit www.chopperpumps.com.

WANNER ENGINEERING

Hydra-Cell T200 Series Medium Pressure Pumps

Wanner Engineering, Inc. introduces its new Hydra-Cell T200 Series Medium Pressure pumps. They feature a seal-less design that avoids the maintenance problems of mechanical or dynamic seals and packing that can leak and wear. With flow rates up to 95 gallons per minute and a maximum pressure rating of 3500 psi (241 bar), Hydra-Cell T200 models are ideal for a variety of high-capacity applications including salt water disposal (SWD), salt water injection, bulk transfer, and hydraulic lift in oil fields, as well as steam generation, reverse osmosis in water and wastewater treatment, mine dewatering, boiler feed, and high-pressure cleaning.

The seal-less design means that Hydra-Cell T200 pumps do not have a leak path and therefore eliminate hazardous VOC emissions and the clean-up and disposal costs of packed-pump leakage. This also eliminates the need for external lubrication and maintenance as well as plunger wear problems associated with packing.

Hydra-Cell T200 Series pumps can run dry without damage, will operate with a closed or blocked suction line, and can pump hot abrasive fluids effectively. The patented, seal-less Hydra-Cell T200 Series pumps employ hydraulically-balanced, multiple diaphragms that enable the pump to handle high pressures with low stress and process abrasive particulates up to 800 microns in size.

For more information, call 612.332.5681, email sales@wannereng.com, or visit www.hydra-cell.com.

YASKAWA

U1000 Industrial Matrix Drive

Increase efficiency in your industrial pumping applications with Yaskawa’s U1000 Industrial Matrix Drive, the product that goes beyond conventional drives, providing outstanding harmonic performance and regeneration in a single standalone compact drive solution.

Enjoy low harmonic distortion and regeneration in a space-saving design, completely without the need for additional components.

Unlike conventional drives, Yaskawa’s Matrix technology creates a variable output by switching directly from the input power (AC to AC), eliminating the DC bus. Additionally, the Matrix drive is a member of the Yaskawa industrial drive family, and provides the same user experience.

For more information, visit www.yaskawa.com.

XYLEM

Godwin CD100S Smart Pump

The Godwin CD100S is ideal for utility and construction applications, as well as emergency response dewatering. The CD impeller, generally used in construction dewatering applications, can be exchanged with a Flygt N-Technology self-cleaning, non-clog impeller, which delivers sustained hydraulic efficiency. This provides customers with the flexibility to tackle stringy, fibrous materials most commonly associated with modern wastewater applications, all with the same pump. The NC100S and CD100S models feature a redesigned pump-end, resulting in 20 percent greater pump uptime and 40 percent reduced service time.

For more information, visit www.xylem.com.

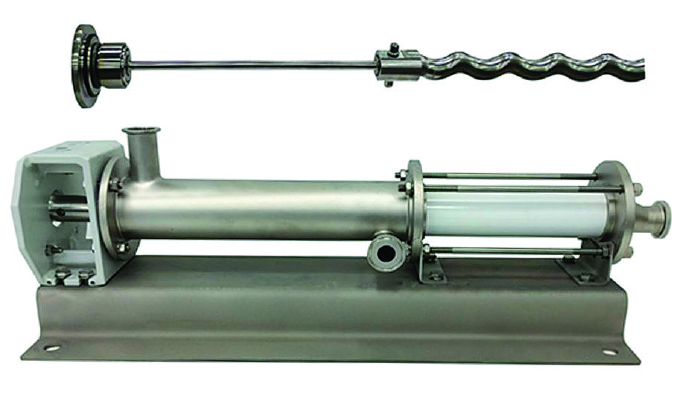

SEEPEX

Sanitary Progressive Cavity Pump with Flexible Rod Drive Train Design

The new BCF range sanitary progressive cavity pump incorporates a flexible rod drive train design for simpler maintenance and CIP/COP processes as well as increased safety. COP is simplified with easier disassembly of rotating parts and without disassembly of the flexible rod. Existing BCS pumps can be upgraded by simply changing the wetted rotating parts. For more information, SEEPEX will be presenting their new 3-A Sanitary Standards certified BCF range progressive cavity pump, with flexible rod drive train design, at PackExpo 2019, booth US-7665, or visit www.seepex.com.

GRUNDFOS

CR Vertical Multistage Pumps

Grundfos releases its newest generation of the legendary Grundfos CR pumps. The much-anticipated, redesigned pumps offer best-in-the-market efficiency and reliability, making them a perfect solution for pressure boosting in various applications. The pumps are being released after extensive research, development, and testing of new hydraulic designs, and are engineered using state-of-the-art production methods, including a fully automated and flexible production line. Once the new generation is fully released, it will include three extra-large flow sizes of up to 580 psi pump pressure. For more information, visit www.grundfos.us/cr.

LIBERTY PUMPS

LSG-Series Omnivore® Grinder Pumps

The Omnivore® Series of grinder pumps by Liberty Pumps meet the demanding needs of commercial and residential sewage applications where difficult solids-handling is crucial. With thousands of units installed globally, the Omnivore has a proven track record in a variety of applications, including homes, motels, schools, shopping centers, and lakefront communities.

The pumps feature patented V-Slice® Cutter Technology developed by Liberty’s own engineering team. This new innovation provides more cuts per revolution for superior shredding performance in demanding sewage applications. The hardened stainless-steel cutting system aggressively shreds, jeans, shop rags, diapers, sanitary napkins, and other difficult solids into fine slurry with less jamming than other cutter designs. A unique open volute eliminates the traditional cutwater found in other pumps—improving solids flow and reducing potential jamming of material in the volute. Other features include a one-piece cast iron body, quick-connect power cord, stainless steel impeller and dual shaft seals. Models are available in single stage or two stage designs—providing maximum pumping heads to over 180 feet. Complete pre-designed grinder systems are available in a variety of basin sizes and backed by Liberty’s three-year limited warranty.

For more information, call 800.543.2550 or visit www.libertypumps.com.

BIONOMIC INDUSTRIES, INC.

Series 9000 Preformed Spray Scrubber

Designed to simultaneously remove solid and gaseous particulates from dryers and other processing operations, the Series 9000 features a specially designed fine droplet scrubbing liquid spray zone within a confined involute section that eliminates any bypass of untreated gas. A fully open, cyclonic entrainment removal section without internal droplet removal components makes the scrubber highly reliable with extremely low maintenance. For more information, call 201.529.1094 or email sales@bionomicind.com. For more information, visit www.bionomicind.com.

INVERTEK DRIVES

Optidrive E3

Simply power on and Optidrive E3 is up and running, providing precise motor control and energy savings using the factory settings. Users can switch between three modes at the touch of a button to optimize Optidrive E3 for their application: Industrial Mode optimizes Optidrive E3 for load characteristics of typical industrial applications, Pump Mode makes energy efficient pump control easier than ever, and Fan Mode makes air handling a breeze, ideal for simple HVAC systems. For more information, visit www.invertekdrives.com.

BASETEK

Polymer Concrete Baseplates

Keeping your rotating equipment level is essential. BaseTek polymer concrete baseplates offer precision flatness while providing significant vibration damping and superior corrosion resistance. Installation time and cost is greatly reduced by eliminating or reducing typical grouting activities in comparison with typical steel designs. Upkeep and preventative maintenance no longer required. Off-the-shelf availably for most ANSI/ASME pump products along with a complete range of custom configurations including the patented GreenShield Foundation Systems.

For more information, visit www.basetek.com.

GREYLINE INSTRUMENTS

AVFM 6.1 Area Velocity Flow Meter

The AVFM 6.1 uses a submerged ultrasonic sensor to measure both Velocity and Level in the channel. The sensor is completely sealed with no orifices or ports. It mounts inside a pipe or at the bottom of a channel. Min, Max, and Total Flow data from the last 365 days is available on the LCD display, or download directly to a USB for easy reporting. At a glance, view flow rate, velocity, level, totalizer, relay status, and important diagnostic information on the LCD display as well. For more information, visit www.greyline.com.

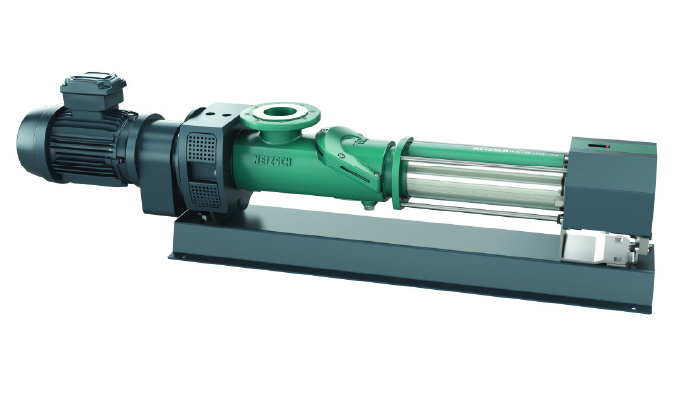

NETZSCH PUMPS AND SYSTEMS

xLC® Stator Adjustment System

The xLC® unit triples the service life of the pump, particularly when conveying difficult, abrasive media. When wear occurs in the rotor-stator system, the new xLC® unit allows the performance of the pump to be re-established by adjusting the preload between the conveyor elements. It is important for the xLC® stator adjustment system that the elastomer in the rigid metal sleeve of the stator is flexible, which was made possible with the development of the proven iFD stator® 2.0. For more information, visit www.netzsch.com.

JWC ENVIRONMENTAL

Muffin Monster® Grinders

JWC Environmental’s 30K and 40K In-Line Muffin Monster grinders have been providing peace of mind to plant operators for over forty-five years. They cut their teeth protecting pumps in wastewater treatment plants around the world and today are used in a wide range of municipal and industrial applications. Wastewater professionals repeatedly turn to JWC’s Monster grinders as the ultimate sludge grinder solution to cut down troublesome solids. It is ready to shred down rags and other debris that can damage pumps, clog valves, and foul treatment equipment—causing costly damage and excessive repairs. Muffin Monster® grinders from JWC Environmental® cleanly and easily shred through wipes, rags, plastics, and other waste materials, preventing costly pump problems and sewer back-ups. The units feature a low-speed, high-torque design that keeps waste flowing freely.

For more information, visit www.jwce.com.

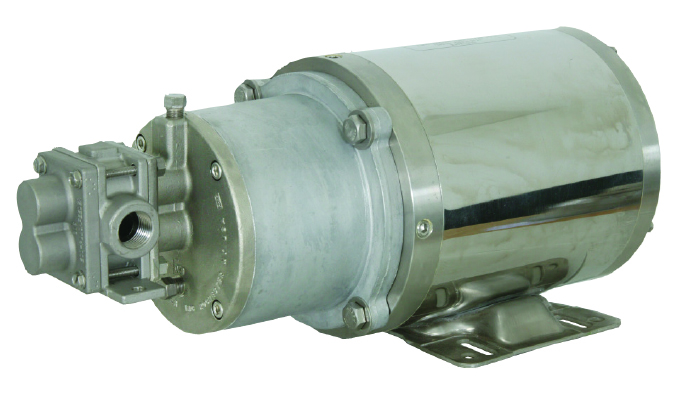

PULSAFEEDER

ISOChem Metering and Transfer Pumps

Sometimes, pumps are purpose-built to address stringent requirements for specific applications—and other times, new applications emerge that fall directly into the sweet-spot of existing pumps.

The rapidly-growing CBD extraction market is a great example of a “new need for an experienced pump”—and ISOChem offers the right mix of features, performance, reliability, price, and immediate availability that CBD extractors need.

ISOChem pumps are compact, magnetically-driven, sealless gear pumps designed to safely handle hazardous and expensive chemicals. For years, they’ve been used in a variety of industrial transfer and metering applications. This past year, newly-enhanced versions of ISOChem (featuring sanitary connections) have seen record growth because they precisely address the needs of CBD extractors.

The ISOChem line offers the flow and pressure envelop needed to address any ethanol extraction process. Its sealless design ensures no leaks, no downtime and minimal maintenance. Its compact footprint makes it easy to incorporate into any skid, and Pulsafeeder distributors prefer ISOChem because of its price point, and the fact that it can be provisioned within hours, and shipped to the customer in a matter of days.

When it comes to pumps for CBD extraction, no single feature dominates. It’s the combination of flow and pressure, sanitary connections, sealless/leak-free reliability, price, and quick availability that have enabled ISOChem to carve its niche in the rapidly-growing CBD extraction market.

For more information, visit www.pulsa.com.

SUNDYNE

LMV-803Lr, API-610, OH3 Pump

The API-compliant OH3 LMV-803Lr is a direct-drive, heavy duty vertical inline centrifugal pump that features Sundyne’s inducer technology and backswept impeller—which can reach unparalleled NPSHr performance without the risk of cavitation.

Recent updates include an enhanced throat bushing which improves seal performance for light hydrocarbon applications; an oil mist option which offers robust loading capabilities and reduces the need for periodic greasing; an updated cryogenic design for NGL recovery, ethane, and LNG production and storage applications; and a smaller hydraulic package which meets a wider range of process parameters and delivers ultra-low NPSHr up-and-down the curve.

The size of the LMV-803Lr is just 25 percent as large as competitive horizontal pumps.

In many instances, a crane is not required to install and maintain the pump because the LMV-803Lr can be installed at grade level, eliminating the need for a sump pit or elevated tower skirt. The small footprint and overall design reduces service and maintenance costs.

The LMV-803Lr is ideally suited for low NPSHr processes that require booster pumps, LNG applications, or downstream refining applications. The LMV-803Lr is also used in industrial applications, such as boiler feeds or seawater applications.

For more information, visit www.sundyne.com.

KROHNE, INC.

Waterflux 3000 Meter Sensor

When combined with the IFC 070 battery powered converter electronics the resulting Waterflux 3070 is the first all-in-one water meter with available integrated pressure and temperature sensor. The new integrated pressure and temperature sensor option allows Waterflux to be used for a wide variety of drinking water network tasks, including pressure monitoring, maintaining the water balance, and district zone management. It can also be used for leak detection in drinking water networks when comparison of pressure and flow values is used as the leak detection method. The meter’s unique sensor design can be installed without the need for any upstream or downstream piping to meet its accuracy specifications.

For more information, visit www.us.krohne.com.

VESCONITE BEARINGS

Water Flinger Polymer Bearings

A Southern African pump manufacturer found that its horizontal centrifugal pumps, as a result of high pressure, had a problem of water escaping from the gland packing—the material that should form a watertight seal around the shaft. This resulted in dirty water being sprayed on to the non-drive-end bearing assembly and, in turn, resulted in seizure, failure, and a high maintenance and down-time cost to replace the bearing assembly. Vesconite works as an alternative material that does not swell or delaminate and has the added advantage of being suitable in dirty environments. For more information, visit www.vesconite.com.

WATSON-MARLOW FLUID TECHNOLOGY GROUP

PureWeld XL Tubing

PureWeld XL tubing, from Watson-Marlow Fluid Technology Group (WMFTG), offers extended lifespan and steady flow consistency, overcoming the technical challenges associated with continuous bioprocessing. The results of a recent study demonstrate significantly longer peristaltic pump life and sustainable flow rate delivery when compared with competing TPE (thermoplastic elastomer) tubing. Continuous processing has the potential to significantly increase the efficiency of biologics manufacture, reducing production costs and hence the price of pharmaceuticals. In order to achieve this, all single-use components must be able to maintain integrity for extended production cycles of up to potentially ninety days.

For more information, visit www.watson-marlow.com.

SCHROEDAHL

TDL Automatic Recirculation Valves

Schroedahl’s, a Circor International brand, self-modulating TDL Automatic Recirculation Valves (ARVs) are designed to keep pumping systems in process, firefighting, refinery, power, and chemical applications modulating and running smoothly, without cavitation or overheating. Without minimum flow, a pump can quickly suffer grave damage, causing downtime and costly repairs—but control valves for recirculation require continuous control of complex equipment, a flow measurement device, control unit, and energy supply. Unlike control valve packages, the self-operated flow-sensitive Schroedahl TDL Automatic Recirculation Valves operate without a separate power supply or any control system—and begin protection immediately once installed.

Schroedahl TDL Automatic Recirculation Valves combine a high-quality main line check valve and the automatic bypass control system in an innovative and durable design—developed by the inventor of automatic pump protection. The valves’ self-actuated integrated bypass control function ensures minimum flow rate, guarding pumps against overheating and cavitation. The systems provide high pump stability—with less vibration and fewer coupling or gear problems—for less downtime and lower maintenance costs. TDL ARVs’ modulation bypass function also offers savings for operators with reduced energy consumption for frequent partial load operation.

For more information, visit www.circor.com/products/valves/pump-protection.

Greene Tweed

WR® 650 PFA Composite

The WR 650 is a next-generation PFA composite with superior dry run characteristics designed to replace metallic wear parts in centrifugal pumps and any other applications where wear resistance is required. Greene Tweed’s WR 650 delivers high chemical compatibility, excellent wear characteristics, and operability from subzero to 500 degrees Fahrenheit (260 degrees Celsius). The advanced material with 3D carbon-fiber architecture, provides a coefficient of thermal expansion comparable to steel over a wide range of temperatures, offering a constant running clearance, no interference, and no efficiency drop.

The WR 650 solution may be applied as stationary wear parts in vertical, horizontal, single, and multistage centrifugal pumps. Greene Tweed products can be used to improve the reliability and efficiency in refineries, chemical plants, power plants, pipelines, and water treatment plants. WR 650 is available in a broad range of stock shapes, ranging from ID1 to OD12.

For more information, visit www.gtweed.com.

ENDRESS+HAUSER

Field Xpert SMT77

Endress+Hauser’s Field Xpert SMT77 is a rugged tablet PC tool for commissioning and maintenance staff to manage field instruments and document the work progress. The SMT77 comes preinstalled with device configuration software and device library—so it is ready to go, right out of the box. The device enables plant asset management in Class 1 Div 1 hazardous areas.

The Field Xpert device library has more than 2,700 pre-installed device and communication drivers, allowing it to work with many different instruments from a wide variety of vendors. It can connect to field instrumentation devices directly via a USB or Bluetooth wireless modem, or via a gateway, remote I/O or multiplexer to a bus system.

The Field Xpert SMT77, therefore, works with virtually every modern field instrument with one click connectivity. To connect the Field Xpert SMT77 to a flowmeter with HART interface, for example, the operator simply clicks on the application, which then prompts the user to select automatic connection and the application connects to the instrument, and the SMT77 is ready to perform diagnostics, configurations, or commissioning with the built-in device configuration software. The SMT77 also supports Endress+Hauser Heartbeat Technology and FieldCare instrument diagnostic and monitoring functions.

For more information, visit www.us.endress.com/SMT77.

NEPTUNE

NSP Series and NXP Series Pumps

Earlier this year, Neptune™, part of PSG®, a Dover company, launched its NSP Series Solenoid Metering Pumps and NXP Series Stepper Motor-Driven Metering Pumps for chemical applications that require reliable and accurate dosing.

Featuring a durable, low-maintenance solenoid drive equipped with double-ball valves, the NSP Series ensures consistent and precise dosing of a variety of chemicals, including acids, alkalis, coagulants, and flocculants. The compact design and easy-to-use control of the NSP Series provide more efficient operation and shorter setup times for the operator. The small footprint allows it to easily integrate into dosing systems with limited space. The NSP Series is available in manual-, analog-, and pulse-controlled models.

Meanwhile, the NXP Series combines the advantages of a solenoid-driven pump with the precision of a motor-driven pump. This makes it an ideal solution to safely feed chemicals in highly accurate, reproducible applications. The NXP Series is fully adjustable to produce a constant supply stream during low-pulsation dosing, and the stepper motor with its wear-free tooth belt dive ensures a homogeneous and gentle dosing process. Available in six sizes, the NXP Series is plug-and-play and includes a universal power supply unit.

For more information, visit www.neptune1.com.

MODERN PUMPING TODAY, December 2019

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!