According to the United States Energy Information Administration, there are almost one million oil producing wells in the United States alone, and most require the use of an artificial lift system. There are various methods of artificial lift which are utilized to increase pressure within the reservoir to push oil to the surface. This allows operators to enhance production and extend well life.

THE ELECTRICAL SUBMERSIBLE ADVANTAGE

One of the most efficient and reliable methods of artificial lift for moderate to high volumes of fluids from well bores is through use of electrical submersible pumps (ESP). It is important for ESP systems that every component stands up to the rigors of high pressures, high temperatures, and direct contact with the well fluids and contaminates common in oilfield environments.

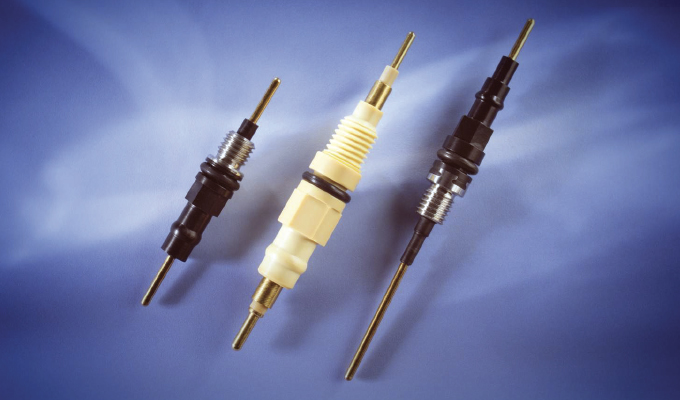

One type of critical component is the electrical thermal insulators that mate with electrical connectors and feedthroughs downhole. Electrical thermal insulators are designed to protect sensitive electrical connectors and feedthroughs transmitting critical data in extreme temperatures and pressure environments. Without an effective insulator, connectors are at risk of not being able to transmit a continuous signal and power to vital surface equipment. This could have serious consequences, such as unscheduled and costly oil well downtime.

Finding an insulation material that can deliver the required electrical performance and reliability while also withstanding the harsh HPHT downhole environmental conditions is critical, but finding the right material is not easy. To address these downhole needs, Greene Tweed has developed a patented cross-linked PEEK thermoplastic, Arlon® 3000XT. This innovative material platform can withstand temperatures ranging from 500 to 572 degrees Fahrenheit (260 to 300 degrees Celsius), environments with high pressure in excess of 35,000 psi, and harsh media such as hydrogen sulfide, methanol, drilling fluids, and well products.

ADOPTED ACROSS THE INDUSTRY

Arlon 3000XT is already being rapidly adopted by global oilfield companies. Let’s see why: Our engineers put Arlon 3000XT through a rigorous test in extreme oil and gas applications. It demonstrated superior performance at high temperatures ranging from 500 to 572 degrees Fahrenheit (260 to 300 degrees Celsius)—typical temperature range in oil wells.

Compared to competitive materials (polyimides, other polyketones), Arlon 3000XT performed consistently even when exposed to fluids at temperatures ranging from 500 to 572 degrees Fahrenheit (260 to 300 degrees Celsius) for 112 days. It delivered superior mechanical property retention and outperformed standard grades of PEEK in tensile strength and Young’s Modulus, showing no statistically significant difference after aging at 572 degrees Fahrenheit (300 degrees Celsius) compared to baseline data (unaged samples). Both surface and volume resistivity were above standard insulative requirements at high temperatures, tested up to 572 degrees Fahrenheit (300 degrees Celsius).

In addition, any exposure even to minimal amounts of water or moisture may irreversibly attack polyimides; while Arlon 3000XT is able to withstand not only moisture but has even withstood the harsh chemical exposure conditions required to successfully attain Norsok certification.

Regarding manufacturability, Arlon 3000XT can be net molded or near net molded with no additional machining steps required. Custom or standard injection molded parts with final machining are also available.

DECADES OF EXPERIENCE AT WORK

From extensive industry knowledge, Greene Tweed knows having a robust material platform you can use in your ESP systems is critical to meeting or exceeding the run life and operation of your artificial lift systems. Let us put our decades of experience and innovative material and product solutions to work for you. Our engineers can design a custom solution for your electrical thermal insulator needs to protect your sensitive electrical connectors and feedthroughs.

FOR MORE INFORMATION

Greene Tweed is a leading global manufacturer of high-performance thermoplastics, composites, and engineered components, including custom-engineered sealing solutions for the aerospace/defense, energy, semiconductor, industrial, life sciences, and chemical processing industries. For more than 150 years, Greene Tweed has remained dedicated to new ideas and high-performance products, providing its customers with solutions that have pushed the boundaries of material science, while exploring and testing the use of new polymers. For more information, visit www.gtweed.com.

MODERN PUMPING TODAY, September 2022

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!