Being a world-class machine designer, manufacturer, field service, and repair company means meeting customer needs across an array of conditions. Recently, Logan Industries International Corporation has successfully delivered a unique, space-saving coiled tubing (CT) reeler suite for OneSubsea, designed to maximize profitability.

APPLICATIONS BEYOND STORAGE

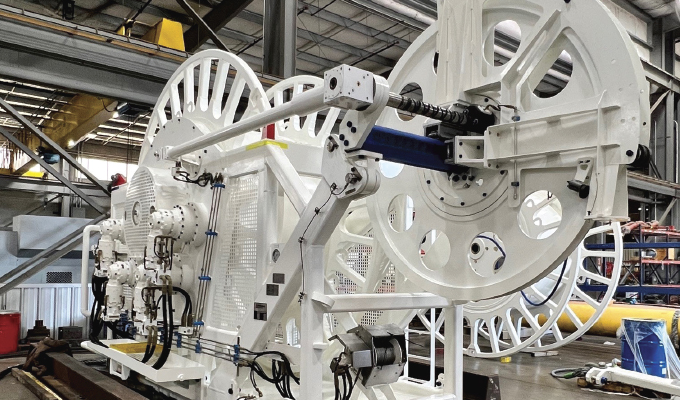

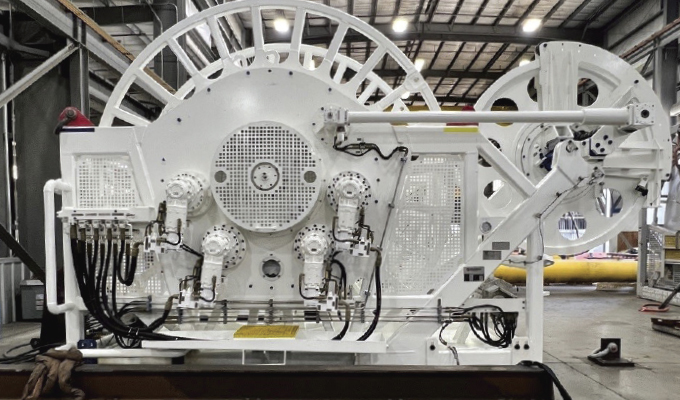

More than simply storage reelers, Logan’s CT reelers are coiled tubing winches, where the reelers provide full torque control for the tubing without the need for a standard injector head. This reduces space required compared to standard tubing reeler / injection head combination, and allows for a larger fluid storage footprint on deck. When the equipment required to handle CT has a small footprint, more deck space can be dedicated to hauling fluid, which increases profitability for the operator.

Whereas Logan has built several sets of these machines in the past with fixed drums, this is the first unit Logan has delivered with a removable drum, which means the unit footprint can remain static on the vessel while the drums can be taken to a shore base for unspooling and respooling. They are transported in a purpose-built DNV lift rated drum basket, fully secured and protected. The swap out drum also makes the machine faster to build, reducing typical assembly time for the drum and drive train from two weeks to two days.

THE NEXT EVOLUTION IS HERE

At 15,000 psi working pressure, 10,000 feet of 2-inch CT was provided on the drum, with live swivel and isolation valves on the unit. The suite of equipment provided for this work includes a spare drum, adapter to allow it to fit into most tubing service spoolers at the tubing manufacturer’s facilities, transport basket, and lifting set along with the reeler, HPU, control stand, and interconnect lines. Logan also provided a purpose-built overboarding platform with a translating / clamshell to accommodate OneSubsea’s unique end connection philosophy.

Logan’s team placed a work deck, dimple connector, test tool, controls, and safeguards on this overboarding platform to give the crew plenty of access to the volume of space under the overboarding point. The overboarding platform also provided a reeler deck loading spreader effect on the vessel’s deck. We believe this is truly the next evolution in coiled tubing deployment offshore, and provides significantly more convenience for our customers. This is one of the most comprehensive reeler equipment suites Logan has had the pleasure to provide, and we expect it to remain in service for quite some time.

CLIENT CLOSE-UP: ONESUBSEA

OneSubsea delivers integrated solutions, products, systems, and services for the subsea oil and gas market. Our company offers a step change in reservoir recovery for the subsea oil and gas industry through integration and optimization of the entire production system over the life of the field. OneSubsea leverages Cameron’s flow control expertise, process technologies and world-class manufacturing and aftermarket capabilities, along with Schlumberger’s petro-technical leadership, reservoir and production technology, and R&D capabilities.

FOR MORE INFORMATION

Headquartered northwest of Houston in Hempstead, Texas, Logan Industries provides precision hydraulic energy and control management system solutions within a range of industries, including oil and gas, lumber, steel, industrial, dredging, mining, and marine. Logan Industries designs, engineers, and manufactures fit-for-purpose equipment. The company provides field commissioning and field service. Logan also performs machine refurbishments and provides rental equipment. Logan backs all of this up with strong engineering and corporate support for challenging projects. Logan Industries holds several manufacturing certificates (API Q1, 6A, 8C, ASME U & R, ISO 9001:2015), and is qualified to work under API 16AR. For more information, visit www.loganindustries.net.

MODERN PUMPING TODAY, September 2022

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!