Growth, progress, prosperity. There’s no shortage of it in North Alabama, which has seen its population grow by 30,000 over the last five years and is projected to rise by a further 24,500 by 2027. Jobs are also on the up, having increased by almost 50,000 in the past five years—with a projected growth of 33,000 more jobs, also in the next five years.

In Etowah County, Alabama’s smallest yet most densely populated county, vibrant Southside (population 8,000—about an hour north west of Birmingham), is its fastest growing city, but this prestigious position held by the place described as the “loveliest village on the Coosa River” has been faced with the recent possibility of being overtaken by other fast-rising locations in the state.

ADJUSTING TO THE GROWING PAINS

With growth, naturally, comes the need for new infrastructure. Southside’s old sewage lagoon system, despite decades of excellent management, had finally reached its capacity. All that growth, progress, and prosperity—but a potential halt on building more homes and attracting more business to the area—without a new wastewater treat “Everything was perfectly in order with our treatment levels,” says David Fry, assistant superintendent for Southside Water Works and Sewer Board, “but we’d reached the point where there was a moratorium on the lagoon, so to keep Southside on track, the city knew it had to invest in a treatment system that would futureproof the well-being and continued success of Southside.”

CDG, Inc., who operate across the whole of Alabama, were brought in to work with the city of Southside to find the best solution. Bordered by the Coosa River in the foothills of the southern Appalachian Mountains, the area is blessed with wildlife, as well as top quality boating and fishing, so not surprisingly, it is very well monitored by Alabama’s Department of Environmental Management.

Scott Trott, P.E., chief strategy officer at CDG, comments, “As always, we wanted to do much more than just collaborate; we wanted to build a unified team with trust, so we brainstormed long and hard with Brandon Sewell (superintendent) and David Fry (assistant superintendent) at the Water Works and Sewer Board to explore all the options.”

He adds, “This included seeing how or if the lagoons could be improved, but they just can’t economically and reliably meet today’s environmental needs. Some poorly maintained lagoons have well-documented issues of unwanted odors, bacterial spread, and nitrogen/phosphorous overload, but the Southside Board and its predecessors had always managed the lagoon system very professionally and successfully.”

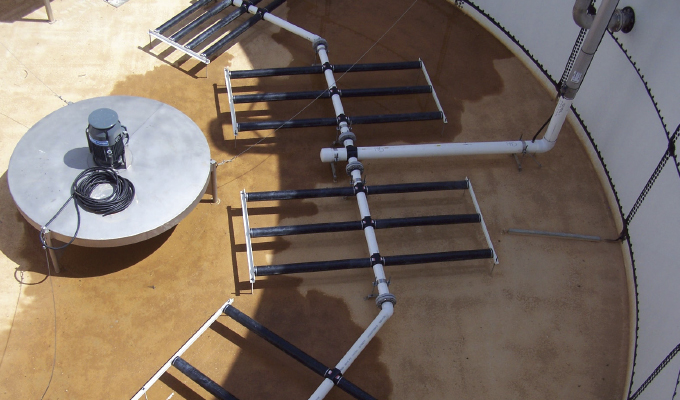

Ultimately, an SBR (sequencing batch reactor) was chosen, one that was very robust—simple to operate—and could be easily scaled up for future needs. A site was identified, and after the equipment opportunities went out to bid, an SBR from Lakeside Equipment Corporation was chosen from its long-established agent in Alabama, the Eshelman Company.

Trott continues, “Bringing the team together, including Aaron Schmidt at Schmidt Environmental Construction, Inc., we started mapping out the project with a detailed analysis so that we all knew where we were, understood what our success would look like, and how every move we made was in that right direction.”

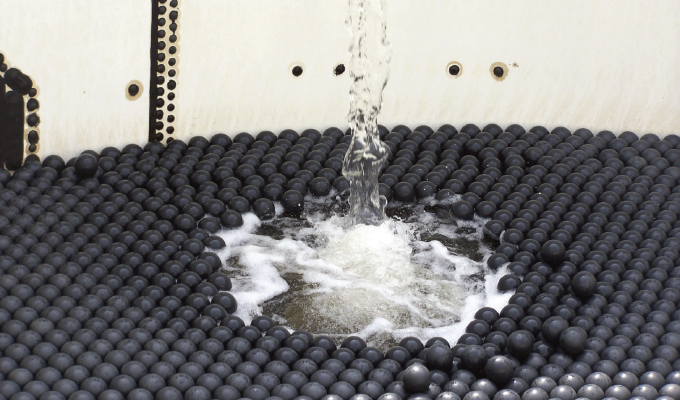

Designed as a cost-effective biological treatment process, Lakeside’s SBR benefits from a fully automated system that treats raw wastewater flow in a single basin using timed based phases to fill, mix, aerate, settle, decant, and waste sludge. It incorporates diffused aeration with mixers to provide optimum mixing and aeration for high oxygen transfer. An innovative decanter minimizes decanting intervals while extending the biological process time. The resultant clear water discharges without foam or floating scum.

LONG-LASTING AND EFFECTIVE

Ed Moore from the Eshelman Company says, “For me, the choice of CDG, Inc. and such a long-lasting and effective Lakeside SBR underlines the city of Southside’s desire to do things properly. The old lagoon system was hampering the growth and prosperity of the city, so it was exciting to see Scott Trott’s forward-thinking design for what was clearly going to be a very well thought out, scalable new plant that would keep Southside one step ahead of the rest for many years to come.”

The new site was laid out so that capacity—peak flow of one million gallons per day—could easily be doubled by building new tanks. Initially, it would only be running at around 150,000 to 175,000 gallons per day on average—or up 300,000 gallons per day, depending on the time of year. The site required a fair degree of earth moving for it to be raised—with ample ground water to contend with – but according to contractor, Aaron Schmidt, this proved a straightforward challenge as the team quickly gelled together.

“Most of the equipment was sourced by the Eshelman Company,” says Schmidt, “so being able to call upon Ed Moore’s knowledge and experience was a big help. Lakeside were also always quick to respond to any questions during the ten months of construction.”

It would be interesting to know just how seamless or otherwise it was when Southside’s first water system was constructed when the city was incorporated in 1957 and constructed its first water system. Now, more than six decades on for its first dedicated wastewater treatment plant, CDG, Inc. through Scott Trott’s design, took great care not to overbuild the new facility, putting a constant review process into place with certified personnel to see the layout from the customer’s viewpoint; carefully considering heights, spaces, and repeat activities—all to make the treatment plant operator’s job easier—without unnecessary obstacles.

TOTAL SUPPORT THROUGHOUT

CDG’s Trott continues, “With designs that aren’t overly-complicated for the sake of it, Lakeside clearly understand the needs of operators, so this, together with being excellent communicators, made everything much easier and enjoyable to work on. Some companies only work well when the sun is shining, so to speak, but as always, you soon find out who you are really working with when you hit a few stumbling blocks—and I can safely say that Jim Aitkenhead and his colleagues at Lakeside were with us from start to finish—total support throughout, taking huge pride in the job. There have been no problems with the SBR. It is very reliable and effective.”

Based on a thirty-five-year cost analysis, with key component assets forecast for a minimum of twenty-five years, the Lakeside SBR comprises five key stages in its process:

- Mix-fill: Raw wastewater is introduced into the basin where it is mixed with the mixed liquor suspended solids (MLSS). This phase is anoxic and can be adjusted to anaerobic for phosphorus release.

- React-fill: Aeration is added as the basin is fed with raw wastewater to create aerobic conditions for BOD and ammonia removal. This phase can alternate between aerobic and anoxic conditions for nutrient removal.

- React: Raw wastewater flow is stopped from entering the basin. Aeration and mixing are controlled to provide final treatment.

- Settle: Aeration and mixing are stopped to allow separation of liquid and solids.

- Decant and sludge wasting: Clear effluent is removed from the surface by the decanter. Near the end of decanting cycle, a set amount of settled sludge is wasted from the system.

Brandon Sewell, superintendent for Southside Water Works and Sewer Board, continues, “From managing chlorine levels at the lagoon, there is obviously far more to a full treatment plant, but that said, the SBR is very easy to operate, with the back-up of the SCADA system and the team always ready with help if required. The Lakeside SBR was the right solution for us. It works really well.”

The Eshelman Company’s Moore adds, “Southside now has a delightful plant to walk around. It has a really good vibe and feel. Considering it has such a high level of design and such rugged equipment, the final cost of $4.3 million is an outstanding achievement by all concerned, especially because the new facility is so easily scalable for the future. This is a great example of a long-lasting investment for the wastewater industry.”

CRUCIAL TO THE CONTINUING SUCCESS AND GROWTH OF THE CITY

Fry, assistant superintendent for Southside Water Works and Sewer Board, concludes, “The final effluent from the SBR looks just like drinking water, which is pretty remarkable when you see where it has come from. Overall, the plant is very maintenance-friendly.

“Maybe it sounds strange to some people, but the new plant is a great environment to work in—and Southside is a great place to live. This new treatment plant is crucial to the continuing success and growth of the city. Now that there is all this new capacity, Southside can welcome the building of more new homes and investment from new business.”

FOR MORE INFORMATION

Dan Widdel is regional sales manager at Lakeside Equipment Corporation. Lakeside Equipment Corporation is an engineering and manufacturing company concentrating on helping to improve the quality of our water resources. Lakeside started in the spring of 1928 to engineer, develop, and provide water purification systems to municipalities and companies throughout North America. For more information, visit www.lakeside-equipment.com.

MODERN PUMPING TODAY, September 2022

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!