By Del Williams

When municipal sewer or storm lines become blocked, the trouble typically began with a growth of tree roots that eventually stopped the free flow of wastewater in pipe. Blockages can also occur due to accumulated hard mineral deposits, grease, silt, or debris. The resulting blockage can lead to sanitary sewer overflows, which are monitored by federal mandate and can lead to citations.

Although the skillful use of high-powered nozzles with forward penetrating jets can sometimes dislodge partial obstructions in smaller pipe, resolving the worst cases in large pipe requires the use of special heavy-duty chain cutter nozzles that can remove even a “wall of roots.”

“For smaller clogs a contractor can use forward-penetrating nozzle jets to clear it. A mini chain cutter might be required for light to medium roots. But any pipe 12 inches or larger with heavy roots or heavy mineral deposits will need a tool with more power and capability,” says Dan Story, operations manager at KEG Technologies, a manufacturer of sewer and storm line products including nozzles, chain cutters, and camera nozzle systems.

Contractors must be cautious, however, when placing cutters into sewer lines to avoid severing utility lines.

“Before a root cutter is inserted into the line, it should be inspected by camera first to prevent cutting a gas or power line and inadvertently causing sparking and explosion,” says Story. “The most efficient way to inspect the area is with a camera nozzle that takes video while cleaning.”

STREAMLINE INSPECTION BEFORE CUTTING

Although a variety of visual inspection options are available, not all are economical in terms of time and labor. Sending a CCTV camera crew to acquire video in sewer line is common. However, this usually involves taking them off other tasks, such as documenting pipe condition to satisfy federal mandates. The sewer cleaning team must also wait for the CCTV crew to arrive and take video before the source and severity of the blockage is identified. Inevitably, this leads to additional production downtime.

Portable video recording contraptions such as a nozzle and camera mounted inside of a carrier exist, but are typically not reliable. Some camera nozzles are specifically designed and integrated for reliable video capture during cleaning. As an example, KEG’s KleenSight camera-nozzle system offers operators the ability to clean sewer and storm lines 360 degrees while recording upright image video, as well as quickly assessing the line without having to use a CCTV camera truck.

For clear, reliable viewing, the device has a self-leveling camera head and provides its own illumination with eighty LED lights while recording high-definition video. Only a jetter hose connection is required—no cables or wires. The camera captures the video in memory. With Wi-Fi capability, the files are automatically date and time stamped for easy downloading to mobile phones, tablets and computers for viewing.

The unit also allows videos to be emailed or sent to the cloud for sharing with supervisors that may need to provide input before chain cutter nozzles are utilized.

SELECTING A CHAIN CUTTER NOZZLE FOR TOUGH JOBS

When a severe blockage is identified, chain cutter nozzles are used. Perhaps the most common type is hydraulic base cutters that utilize a hydraulic motor, but instead of hydraulic oil use the velocity of the nozzle’s water to spin the cutting blade.

While relatively inexpensive, hydraulic base cutters often do not supply sufficient power or torque to cut heavy roots or hard mineral deposits. In thick root systems, the units may not get the job done and can also stall or seize up.

For the toughest blockages, chain cutter nozzles that utilize the power of high-efficiency nozzle water pressure provide much more torque to cut through a thick root mass. When high-pressure water enters the chain cutter nozzle chamber, it is directed to spin the cutting chains at high velocity with enough torque to avoid seizing.

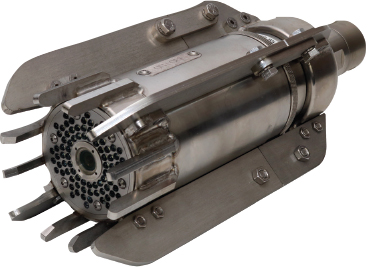

As an example, the SuperNova 4000 Chain Cutter by KEG has a high speed, high torque, water driven design that can eliminate heavy root blockages as well as scale, rust, mineral deposits, hardened grease, and even protruding taps such as concrete and cast iron. The chain cutter is designed for use in offsets, pipe rips, and protruding taps. Intended for use with 6- to 16-inch pipe, the cutter can be adapted for use with up to 48-inch pipe and is compatible with all materials (PVC, clay, iron, concrete).

When municipal sewer or storm line contractors are faced with impenetrable blockages and the risk of federal citations for sanitary sewer overflows, pairing the latest, most effective designs of camera nozzles for easy inspection along with chain cutter nozzles can quickly resolve the issue and get the pipes flowing freely again.

FOR MORE INFORMATION

Del Williams is a technical writer based in Torrance, California. KEG Technologies Inc. is headquartered in Spartanburg, South Carolina. KEG`s patented fluid mechanics directs high pressure water from a truck or jetter hose in a manner so efficiently they were granted a United States patent, meaning operators can usually clean pipes using less pressure, less fuel consumption, and less time than other less efficient nozzles. For more information, call 866.595.0515 or visit www.kegtechnologies.net.

MODERN PUMPING TODAY, December 2021

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!