By Soren Rasmussen, Landia

When it comes to industrial wastewater, few industries provide the challenges of poultry processing. Beside the strict regulations that come with this particular aspect of food processing, the content of the stream itself can be difficult to manage without frequent clogs, harsh wear, and flow shutdowns. In the examples below, we’ll show how Landia’s pumps and mixers answered the call and provide the solutions this global industry relies on.

CHICKEN RUN FOR CHOPPER PUMP

First up, Ferrier Pumps has brought about a successful solution to a tricky wastewater application at a chicken processing plant in Scotland. With washdown water containing feathers, feces, and sawdust, achieving the required flow rate was critical, as was the selection of a pump that could cope with the difficult solids.

As part of its design, which included two screens, pipework, control panels, and flow meter, Ferrier Pumps (established 1981) brought in a submersible chopper pump from Landia, as Peter Ramsay, sales engineer, explains, “Critically, we knew that if the minimum self-cleansing velocity could not be not maintained for this packaged pumping station, then the solids in the pumped product would settle out causing blockages.

“We’d also seen from previous experience that the Landia chopper pump is extremely effective and reliable—even when having to deal with very hard-to-handle solids such as feathers. We’ve had no issues at all. It really is the best pump for these challenging applications”.

Operating at 1,500 rpm, the submersible Landia chopper pump installed by Ferrier Pumps is designed with its classic external knife system that relentlessly chops solids before they get inside the pump’s casing—continuously reducing particle sizes for the benefit of the process.

POULTRY WASTEWATER INSTALLATION BY WATERMARK PROJECTS

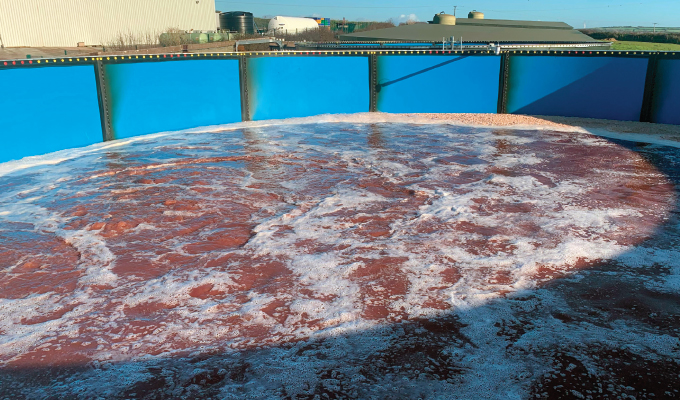

Next, Watermark Projects (part of leading engineering services company, W.A Cooke & Sons) has introduced a Landia mixing system to help handle wastewater at an expanding organic poultry producer in South Wales. Prior to the effluent being treated by Watermark Projects’ bespoke DAF (dissolved air flotation) as part of their design and build service, Landia’s AirJet will keep the balance tank aerated, ensuring that solids are kept in suspension.

Comprising a Landia chopper pump and a venturi nozzle (ejector) that sucks in air (and, therefore, oxygen) and then mixes the wastewater, the AirJet eliminates the need for compressors, bottom-mounted diffusers, and advanced controls.

Alistair Fielding, water projects manager for Watermark Projects, says, “Landia equipment is always very reliable, easy to install, and maintain. We know we can depend on it to deal with the peaks and troughs of this application, including after clean-down in the poultry processing plant when the wastewater is more contaminated. Working on the specification with Landia was very straightforward. They are always quick to respond.”

He adds, “Together with our DAF system, which is built in-house, Landia’s AirJet plays an important part in the help we are giving our poultry customer in reducing their environmental impact—significantly reducing their operational costs, as well as ensuring that they achieve local discharge consent.”

The Landia MPTKR-I chopper pump for the externally-mounted AirJet, is a soft-start, 1,500 rpm, 7.5kW unit, mixing and aerating screened poultry effluent with a pH of 4 to 8 in an above-ground 79,000-gallon steel balance tank.

MIXING AND AERATION SOLUTION FOR POULTRY PLANT EFFLUENT

Finally, Landia has supplied stainless steel mixers to a large poultry plant in the West Midlands, where previous equipment had failed due to corrosion. For the customer, a major supplier to supermarkets, the installation of the 4kW, 1,500 rpm mixers will also introduce much-needed air into the process to eliminate odors.

Serving 26,000-gallon balance tanks, the Landia PODBR-I submersible mixers/aerators simultaneously mix and aerate the acidic, screened poultry plant effluent and prevent septicity from occurring.

Landia’s Paul Davies comments, “For smaller tanks where a little oxygen is required, together with thorough mixing, the Landia direct-drive mixer/aerator provides a one-stop solution, because it performs both jobs in a single operation. For this project, our fully-cast stainless steel units were specified, although we also offer a cast iron variant for less aggressive effluents.”

Landia has decades of experience worldwide in supplying mixers, aerators, and pumps for food industry effluent applications, with a growing customer base that extends around the world.

FOR MORE INFORMATION

Soren Rasmussen is the director of Landia, Inc. For more information about Landia’s range of applications, call 919.466.0603, email info@landiainc.com, or visit www.landiainc.com.

MODERN PUMPING TODAY, December 2021

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!