Pump operators should use filters and regulators when needed to condition the air supply. This encourages more reliable pump performance and reduces equipment wear and related energy costs. Air intake filters for the pumping system are designed to remove contaminants from compressed air, preventing damage, and reducing production losses due to contaminant-related downtime. There are three primary types of filters—general purpose to remove water and reduce abrasive contamination, coalescing to remove oil aerosols, and particles down to 0.3 micron and vapor. General purpose and oil removal filters are selected by flow capacity.

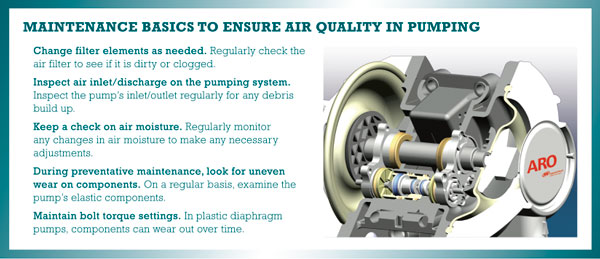

AVOID DIRTY AIR PROBLEMS WITH THE RIGHT ACCESSORIES AND REGULAR MAINTENANCE

Operators should size filters based on OEM-recommended flow ratings and always install filters in the airline upstream of regulators, lubricators, control valves, and air-operated equipment. In most cases, higher-quality air filters provide a lower pressure drop, increase overall efficiency and extend service time. When comparing filters, operators should consider both pressure drop at in-use and maximum flow levels.

Over time, all filter elements reach their contaminate-holding capacity due to dirt, scale, and, rust, causing the pressure differential across the filter to rise. General-purpose elements should be changed when the pressure drop is less than seven psi, while higher-efficiency elements can be replaced at 10 psi. If the filter is outfitted with a pressure-drop indicator, it will automatically signal when a filter replacement is needed.

Filter-regulators, or “piggybacks,” combine the functions of both a filter and regulator. Piggybacks are compact and often fit the bill when space is constrained. Filter regulator lubricators (FRLs) take air from a compressor, which can be hot, wet, and dirty, and make it safer for use in the pumping system.

FRLs come with different filter elements and can be modified with various springs, depending on the filtration and air regulating requirements. Factory assembled and tested, these units save both time and the cost of building an integrated system from individual components. When selecting an FRL, operators should look for one with standard safety features such as locking bowls, lockout, check, and soft-start valves to safely control and manage the air supply.

The FRL will direct the excess moisture from the air stream to the bottom of the filter bowl. The filter housing should be drained daily to release any condensate. Choosing one with an automatic drain option simplifies this process, saving time and protecting the system from water re-entrainment.

SOME APPLICATIONS REQUIRE ADDITIONAL LUBRICATION

In select circumstances additional lubrication may be necessary including applications with a high cycle rate, extremely poor air quality conditions or when nitrogen is being used to run an air operated pump. This requires an air-line lubricator that adds controlled quantities of non-detergent oil into the system to deliver a constant ratio of oil to air flow.

Pump manufacturers provide charts to help users determine lubricator pressure drop at the required flow rate and pressure. If you have need of a lubricator, install it as close as possible to the pump and after any filter-regulator assembly. A quality grade of 80-90 white non-detergent oil or straight 90 white non-detergent oil not to exceed one drop per minute is recommended. (Note: Oil grade recommendations are specific to ARO/Ingersoll Rand pumps and may or may not apply to other brands).

CONCLUSIONS

With air-operated diaphragm pumping systems, good air quality is critical to reliable and efficient pump performance. Maintaining clean air requires selecting a pump capable of handling a wide variety of air intake qualities, installing the right accessories and regular maintenance. A fluid management expert can help identify the necessary steps to keep down costs and minimize downtime related to air quality issues. ◆

For More Information:

Oakley Roberts is vice president of product management at ARO. ARO is Fluid Intelligence—and a leading worldwide manufacturer of fluid handling products that are expertly engineered to deliver performance and serviceability, enabling customers to achieve the best total cost of ownership. For more information, visit www.arozone.com.

____________________________________________

MODERN PUMPING TODAY, February 2016

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!

![]()