Motor testing is among the most common yet underutilized diagnostic and measurement tools that yields an incredible return on investment. The following case study illustrates this point. In 2015, a motor distributor in the Netherlands provided a 17-kilowattt, 400-volt motor to a local hospital. The hospital rented a portable crane to install the motor onto the roof of the building. The motor is used to operate a fan that is mounted on the hospital’s roof. However, not even a full year into its service life, the motor suddenly stopped running, so the motor distributor was contacted for field service, troubleshooting, and on-site support.

DIAGNOSING THE PROBLEM

The motor had been connected to a variable frequency drive (VFD), and when the motor stopped running, the hospital’s maintenance technician reset the VFD. The motor did start, but unfortunately, the VFD shut the motor down again. Next, the technician performed an insulation-to-ground test and determined the motor winding was not shorted to ground. Using a digital multimeter, he then measured phase resistance and learned the phases were not open. The motor testing tools the technician used pointed to a “good” motor; therefore, they decided to replace the VFD.

After the new VFD had been installed, the motor started up but did not continue to run. Much to the technician’s chagrin, they were experiencing the same problem, which compelled the hospital’s maintenance manager to contact the distributor who had supplied the hospital with the motor.

The responsive motor distributor, who has a service center and support staff, sent one of their technicians to the hospital to test the motor. The service center technician used a meg-ohm meter and digital multimeter to determine that the motor was not grounded and the phases were not open, which was no different from the previous test results. Since the motor still did not run, the decision was made to replace the motor.

A crane was brought in to remove the motor from the roof of the hospital and allow a replacement motor to be installed. The replacement motor started and operated normally, confirming the new VFD was working as intended. The “suspect” motor was sent to the service center for a more thorough inspection.

THE SOLUTION: THREE MINUTES OF MOTOR TESTING

An All-Test Pro 5 was used to perform a de-energized, non-destructive motor circuit analysis (MCA) test at the service provider’s facility. Motor circuit analysis evaluates the condition of the electric motor connections, stator, and rotor in just minutes.

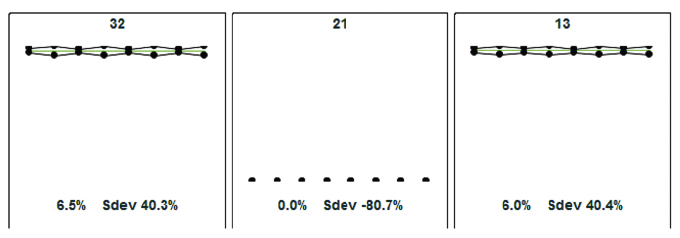

Using the AT5, connections were made to the three phases of the motor and a static test was performed. Next, the motor shaft was manually moved during the dynamic portion of the 3-phase test, and at the end of the test the instrument showed the results.

When performing the dynamic test between phases 2-1, it became clear that this was the phase that had the problem.

LESSONS LEARNED

Owners and Operators Can Reduce Maintenance Costs

A 17-kilowatt, 400-volt motor is not expensive, but when it is mounted on the roof of a building, and the owner has to rent a crane to lift that motor for installation and removal, the cost to the owner can become extremely expensive when it comes to maintenance and reliability. If the hospital’s maintenance team had owned and utilized a motor circuit analysis instrument such as All-Test Pro units, then they would have been able to tell right away that the motor had been the “bad actor” and not the VFD. Many hours were wasted by ordering and installing a new VFD when it had not been the true cause of the problem.

Distributors and Suppliers Can Improve Quality Assurance

Motor distributors and suppliers should implement an additional quality control measure prior to delivering new or off-the-shelf motors to their customers. Spending three minutes to check the condition of motors will help distributors and suppliers avoid warranty issues and increase customer satisfaction.

CONTINUING TO IMPROVE

Since the time of this success story, All-Test Pro has continued to develop and manufacture reliable motor testing equipment to meet the needs of the industry. The newest design, the All-Test Pro 7, uses the company’s proven, patented technology to look beyond vibration, temperature, and ultrasound test methods—giving technicians instant answers on a motor’s health. It represents the seventh generation in product innovation that ensures the reliability of motors in the field and helps to maximize the productivity of maintenance teams everywhere.

Technicians can use the All-Test Pro 7 to boost motor testing methods. Test any motor’s resistance, stator, rotor, contamination, and insulation stats all on one device and receive accurate diagnostics within as little as a few minutes.

With the All-Test Pro 7, technicians can use the patented stator and rotor signatures to test the squirrel-cage rotor and stator with a single assessment. Technicians can also diagnose common fault types using this product’s patented test value static (TVS), which provides a sum calculated from a three-phase MCA static assessment.

This product tests every AC motor type. It evaluates the electrical health of synchronous, single-phase motors by assessing their stator wings, rotors, cables, and other components.

FOR MORE INFORMATION

Since 1985, All-Test Pro, LLC has provided industry with the most advanced predictive maintenance testing and troubleshooting tools for AC and DC motors, coils, windings, transformers, generators, and more to a wide range of industries worldwide. With a full line of testing instruments, software, accessories and training programs, All-Test Pro has the tools you need to perform advanced non-destructive motor testing and analysis for both de-energized motor circuit analysis and energized electrical signature and power analysis. The extensive capabilities of the instruments, coupled with dependable post-sale training and technical support, ensure improved productivity, reduced downtime, and a rapid return on investment.For more information, visit www.alltestpro.com.

MODERN PUMPING TODAY, May 2022

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!