In recent years, the demand for clean and affordable energy has increased the popularity of gas turbine power generation in industrial and commercial co- generation, or co-gen, power plants. Co-gen power plants require gas pressures in the range of 250 to 750 psig to operate their turbines in an optimal fashion. Interstate gas pipelines transport gas at different pressures—ranging anywhere from 30 to 125 psig. In order to boost incoming gas pressures to levels required by turbines, many co-gen facilities at refineries, chemical plants, hospitals, universities, and other industrial plants are deploying Sundyne fuel gas boosters.

PLAYING A VITAL ROLE

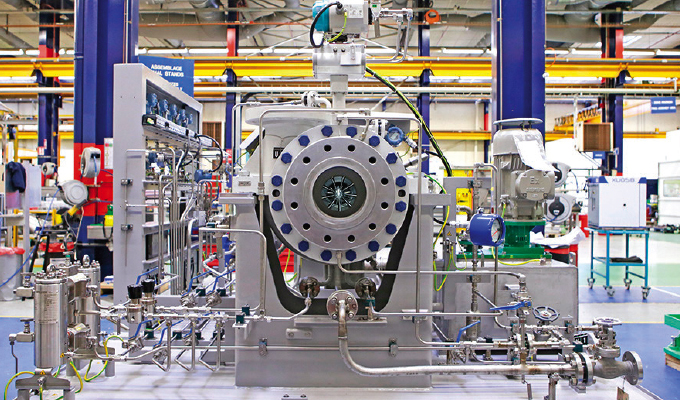

The fuel gas booster is one of the most important pieces of equipment in co-gen power plants, because if the fuel gas compressor fails, the entire power plant stops. Common requirements for fuel gas boosters include high efficiency across variable suction pressures and several gas turbine operating modes, a small footprint, simplified installation, and short delivery times.

KEY VALUES ARE CRUCIAL

To address these requirements, Sundyne compressors feature a design that emphasizes the following key values for the industry.

High Efficiency

Sundyne’s high-speed digital control system integrates all the compressor control functionality in a single system—including surge protection, load-sharing capabilities, compressor-switching, and discharge pressure control. This system has been designed to provide the highest efficiency and reliability, and it can be configured to control compressors in multiple configurations, including variable inlet guide vanes, suction throttling, variable speed, and/or gas recirculation.

Safety

Unlike alternative sealing arrangements such as labyrinth, carbon rings, or single seal configurations—Sundyne’s Tandem Dry Gas Seals configuration is the only sealing arrangement to provide a fully controlled gas emission system. This oil-free operation avoids fuel gas contamination and assures greater process stability. Sundyne’s oil-free design eliminates concerns related to oil contamination. For fuel gas boosting applications, oil content should be less than 1 part per million to guarantee optimal gas combustion in the turbine. Compared to alternative technologies, such as oil-flooded screw compressors, Sundyne’s technology eliminates oil contamination without relying on filtration or separation systems.

Pulsation-free, Smooth Gas Flow

Fuel gas boosting compressors need to continuously deliver a steady supply of fuel gas at pressures needed for optimal gas turbine operation, under all load conditions. Sundyne’s centrifugal technology is specifically designed to deliver smooth, pulse-free flow.

Small Footprint

Now 75 percent smaller than volumetric compressor technology, Sundyne’s single-skid packages eliminate the need for large foundations and lengthy installations, making them ideally suited for smaller co-gen facilities (or offshore units) where space and manpower are limited.

Minimal Maintenance

Reducing maintenance and maximizing uptime are key requirements for profitable power generation. Sundyne compressors are designed for five-year minimum uninterrupted operation.

Shorten Delivery Times

Sundyne fully-integrated compressor trains include auxiliary systems such as: air/water cooled gas heat exchangers; nitrogen generators; valve skids, and all the associated monitors and controllers. As a result, third-party packages are not required, which shortens delivery times. While many Sundyne gas compressors are built “fit-for-purpose,” Sundyne also manufactures units to meet stringent API 617 standards.

THE DEMAND IS RISING

Ever-growing demand for cleaner and more affordable energy is increasing the popularity of gas turbine power generation in industrial and commercial power plants—and most of these plants prefer centrifugal compression to boost fuel gas from pipeline pressures to the higher pressures they require. With more than fifty years of technological development and investment, Sundyne gas compressors are specifically tuned to handle fuel gas boosting applications in any type of plant.

FOR MORE INFORMATION

Colin Guppy is Sundyne’s chief commercial officer. He is responsible for developing strategies and tactics for Sundyne’s chemical industry sector. He can be reached at colin.guppy@sundyne.com. Sundyne has assembled industry-leading brands that provide customers with a wide range of fluid and gas handling services and solutions. Brands like Ansimag, HMD Kontro, and Marelli have broadened the original Sundyne portfolio for a wider range of markets. Sundyne equipment can be built to most standards, including ANSI, ISO, and API. For more information, visit www.sundyne.com.

MODERN PUMPING TODAY, May 2022

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!