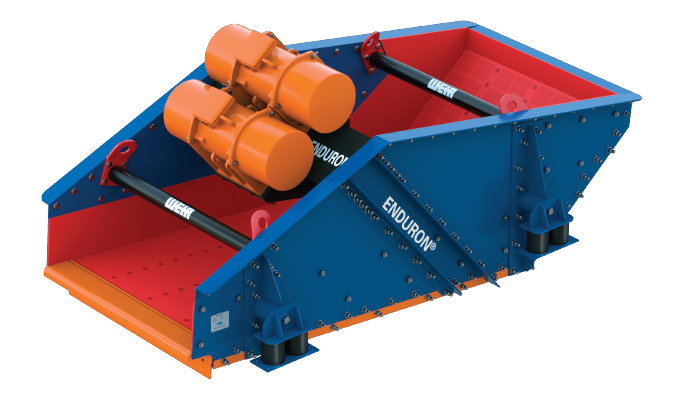

The Enduron dewatering screen plays an integral part in a plant’s success, combining effective particle classification with robust wear life. When in operation, the Enduron dewatering screen receives the hydrocyclone feed, which is between 65 to 70 percent solids content by weight, and produces a dewatered product ready for sale.

The screens are linear-motion and inclined uphill—meaning that product is moved up a 5 to 10 percent inclination, which is only achievable through linear motion excitation. Gravity causes the water to run back downhill into the sump, producing a dry sand product.

Enduron dewatering screens use an apogee designed to achieve a cut size of 300 microns, which combines with a large compact bed of sand to filter trapping fines less than 300 microns. Our screens utilize epoxy adhesive between all mating surfaces to protect against corrosion. Additionally, an all-bolted construction with locking bolts ensures the overall structural integrity of the screen.

These robust screens also feature Linatex premium rubber on all key areas of wear. This industry-leading wear material is complemented by the Enduron dewatering screen’s first-class manufacturing process. The fabricated components are full-penetrated welded, heat stress-relieved and validated through a range of non-destructive testing including x-ray measurements and die penetration testing to produce a screen you can rely on.

For more information, visit www.global.weir.