The city of Santa Cruz, California, wastewater treatment facility processes an average daily flow of 10 million gallons (3.7 billion liters) per day, providing regional wastewater treatment and disposal for both the city and Santa Cruz County Sanitation District, including the communities of Live Oak, Capitola, Soquel, and Aptos. In operation since 1928, the facility has undergone numerous expansion projects to accommodate growth in the region and now boasts a rated design capacity of 17 million gallons (6.4 billion liters) per day.

Aiming to achieve better visibility and reduce energy consumption, the facility recently modernized its exterior area and site lighting, upgrading from high-pressure sodium (HPS) and mercury vapor (MV) fixtures to new Dialight DuroSite® LED fixtures in several areas. As a result, the plant has reduced lighting energy usage and cost by more 50 percent, significantly lowered CO2 emissions, and realized a dramatic improvement in visibility that contributes to more robust security throughout the facility. With fixtures that are expected to last more than ten years, the project will pay for itself in just a third of that time.

THE CHALLENGE

With hundreds of fixtures to light its exterior structures twelve hours a day, seven days a week, the Santa Cruz treatment facility previously used a combination of high pressure sodium units ranging from 70W to 400W and mercury vapor fixtures in 175W to 400W models. For safety and security purposes, the entire facility is under 24/7 closed-circuit television surveillance, yet the poor quality of light emitted by the antiquated fixtures hindered visibility and reduced the image clarity of the closed-circuit system.

In addition, the HPS and MV fixtures required constant maintenance to change bulbs and ballasts, costing the plant both money and valuable personnel time. Not to mention, the cost of hazardous material disposal for the bulbs added to the ongoing maintenance expense and the environmental impact.

THE SOLUTION

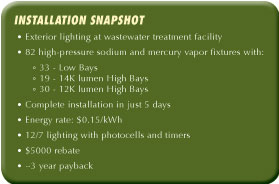

As part of a citywide Climate Action Program to reduce energy consumption and to resolve its lighting challenges, the facility experimented with several LED lighting solutions, including one from Dialight. Impressed with the way the Dialight fixture outperformed the others, the facility ultimately chose Dialight to replace eighty-two fixtures in its solids dewatering building, pre-aeration and trickling filters with the company’s DuroSite LED fixtures, including thirty-three Low Bays specially designed for areas of low clearance, and forty-nine High Bays—nineteen with 14,000 lumen output and thirty with 12,000 lumen output.

The entire changeout took just five days—about thirty to sixty minutes per fixture. The 12/7 lighting was outfitted with a combination of photocells and timers, taking advantage of the Dialight LED’s instant-on capabilities.

THE RESULT

LED fixtures typically draw less than half the wattage of high pressure sodium and mercury vapor (on average). With the new fixtures, the Santa Cruz facility reduced its lighting energy usage and cost by more than 50 percent, significantly lowered its CO2 emissions and realized a dramatic improvement in visibility that contributes to more robust security throughout the facility.

With each fixture expected to last up to ten years, the retrofit has reduced lighting maintenance and costs for the next decade. A rebate was also approved through a local incentive program, based on energy savings, and the entire project will pay for itself within three years. ■

FOR MORE INFORMATION

With a high-specification range of products Dialight is uniquely positioned for a number of long-term global growth trends, many of which are driven by government regulations and environmental initiatives. These include the current global infrastructure build-out, and the need for improvements to the efficiency, reliability, and productivity of the electrical grid. For more information, visit www.dialight.com.

_________________________________________________________________________

MODERN PUMPING TODAY, February 2014

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!

![]()