Situated on the North Sea coast of North Yorkshire, England, the beautiful town of Scarborough has been welcoming tourists and holiday travellers for over three centuries. Established as the first seaside spa resort along the Yorkshire coastline, the town has two designated beaches for public use: North Bay and South Bay. The quality of the water at these beaches differs. While North Bay already boasts the very highest standard under the current European Union water directive, the waters of South Bay have been playing catch up to earn the designation—earning the area a “Blue Flag” label, a reference to the EU-style pictograms noting clean water on popular public beaches.

CHASING THE BLUE FLAGS

For the past three years, Yorkshire Water has been investing millions to improve local wastewater pumping, storage, and treatment facilities in Scarborough to meet the requirements of the European revised Bathing Water Directive. The goal is to reduce the chance of untreated water entering the sea during times of heavy rainfall. The work should ensure Scarborough’s beaches are even cleaner. By making these improvements Yorkshire Water can play a huge part in securing the highest standards of water quality for the town—helping make both Scarborough North Bay and South Bay eligible for Blue Flags in the future.

Bedford Pumps Ltd has been a vital partner in these efforts and has now completed installation on the first of Yorkshire Water’s pivotal pumping stations situated on the picturesque coastline of Yorkshire. The works are part of an £110 million ($182 million US) investment by Yorkshire Water to ensure that Yorkshire’s beaches and bathing water are among the best in Europe. A new European Bathing Water Directive is due to come into force in 2015 and this investment should ensure an “excellent” standard for water quality with the ability to secure some coveted Blue Flags for Yorkshire’s beaches.

THE BENEFIT OF EXPERTISE

Toll House Sewage Pumping Station in Scarborough is the first to benefit from Bedford Pumps expertise with three suspended bowl pumps for pumping storm water. Toll House SPS is located on Scarborough’s peninsula in an extremely challenging location, and as such is Yorkshire Water’s most significant project in Scarborough, costing the company approximately £10 million ($16.5 million US) at this site alone. The pumping station will encompass a new storm water storage tank capable of holding 1.05 million gallons (4000 cubic meters) of storm water, which will minimise the risk of any untreated water entering the sea during heavy rainfall. Bedford Pumps have manufactured three colossal storm transfer pumps which will discharge the excess storm water from the storage tank out to sea.

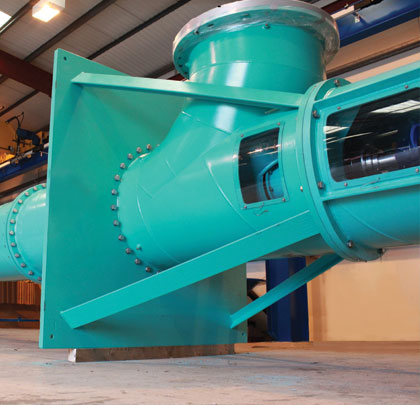

Pump being installed at Toll House SPS on Scarborough’s seafront.

Bedford’s three storm water pumpsets (one duty, one assist and one standby) are of a mixed-flow bowl design with steel rising mains, support plates and motor stools. As Toll House pumping station is situated on the coastline, the open, mixed-flow impellers have been manufactured in bronze to address the potential corrosion problems associated with the saline environment. Each pump is designed to discharge at 54525 gallons per minute (3440 liters per second) at 33.1 feet (10.1 meters) head with a BEP of 86 percent, and driven by a 12 pole 450 kilowatt motor.

BIGGER AND BETTER

Bedford Pumps will shortly commence the second of the trio of pumping station upgrades for Yorkshire Water. Scalby Mills Pumping Station, also situated in Scarborough, will be supplied with four wet well submersible volute pumpsets for handling raw/screened sewage. The order offered Bedford Pumps a challenging design criteria requiring the pumping of solids and stringy material whilst discharging at high heads with low vibration levels. The pumps will deliver a duty of 7021 gallons per minute (443 liters per second) each at a head of 221.8 feet (67.6 meters), making Scalby Mills probably the largest submersible sewage station in the region in terms of power.

The third and final pumping station to benefit from Bedford Pumps expertise is Bridlington Wastewater Treatment Works, which will require four suspended wet well bowl pumps for storm water protection. The construction will be similar to the Toll House units and designed for a duty of 39,625 gallons per minute (2500 liters per second) at 26 feet (8 meters) head and driven by 288 kilowatt 12 pole motors.

A SUCCESSFUL COLLABORATION

Bedford Pumps is looking forward to be working once again in collaboration with civil contractor Morgan Sindall Grontmij (MGJV). In the near future, they will be providing Yorkshire Water with three pumping station upgrades to ensure that the beautiful Yorkshire coastline remains exactly that. ■

ABOUT THE AUTHOR

Lucy Ogden is the marketing manager for Bedford Pumps Ltd. For further information, email her at lucyo@bedfordpumps.co.uk, call 01234.852071, or visit the Bedford Pumps website at www.bedfordpumps.co.uk.

_________________________________________________________________________

MODERN PUMPING TODAY, February 2014

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!

![]()