In the conclusion of this series, we will examine the necessity of a functional precision alignment program, specifically how savings will begin to accrue whenever an alignment program begins, whether at initial commissioning of equipment or after machines are already in service. For example, a misaligned pump uses much more power than it should.

Factoring in the cost of that wasted power, we can calculate the savings. Energy prices vary widely, but using a mid-level global price of about $0.16 per horsepower, we see that precision alignment of that single pump could lead to an immediate savings of almost $1,700 per year. Aligning multiple or larger machines translates to a corresponding and substantial reduction in operating costs.

A PRECISION ALIGNMENT PROGRAM: RETURN ON INVESTMENT

With precision laser alignment, savings will begin to accrue whenever an alignment program begins, whether at initial commissioning of equipment or after machines are already in service. Program expenses can be recouped very quickly. For example, measured solely against operating costs, an alignment program that includes just five 270 horsepower machines could cover the expense of introducing precision alignment in as little as one year.

Alignment programs benefit from economies of scale; the greater the number of machines aligned, the more quickly the purchase cost of alignment equipment will be recouped.

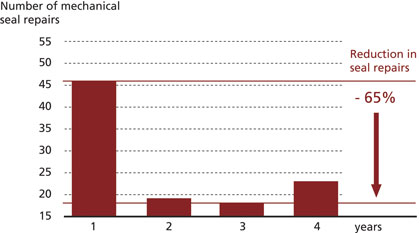

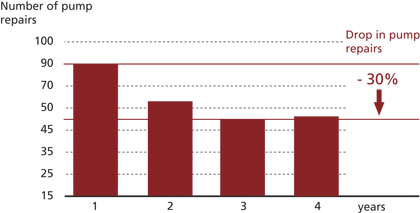

Moreover, precision alignment offers benefits in addition to the immediate energy savings. Implementation of a regular precision alignment program means that repairs on mechanical seals will decline by up to 65 percent; pump repairs can drop by 30 percent; and the expected service life of bearings may increase by as much as 50 percent.

When savings on maintenance costs like these are included in the calculation, a precision alignment program can achieve returns on the investment almost immediately.

ESTABLISHING AN ALIGNMENT MAINTENANCE PROGRAM IS KEY

The guaranteed benefits of precision alignment make establishment of a laser alignment program essential; the innovative laser technologies developed by PRUFTECHNIK make it possible. PRUFTECHNIK laser alignment and condition monitoring instruments are designed to be user-friendly and intuitive. Sag-free brackets are available for any type of shaft or coupling, and they set up quickly, even in tight or hard to reach spaces. Simple onscreen wizards make it easy to enter the required machine data. PRUFTECHNIK’s precision laser system can check alignment while machines are in operation and over time to reveal the true alignment condition of a “live” machine. Alignment software allows to present alignment data graphically in the form of a trend line or chart in order to monitor the alignment condition over time and help detect underlying machinery issues. With a resolution of 1 micron (0.00004 inches), accurate alignment values and tolerance checks guarantee precise, money saving results. Reports that conform to ISO requirements are generated directly from alignment instruments and can be sent wirelessly to anywhere in the world.

When faced with spiraling energy costs, precision alignment can be an easy way to fight back. For companies that use rotating equipment, a plant-wide alignment program can save millions of kilowatts and tens, or even hundreds of thousands of dollars in energy costs. The added benefits of machine reliability and production improvement make a precision alignment program a cost-saving essential. PRUFTECHNIK precision alignment systems and expert alignment engineers provide the products, services, and support that deliver precision alignment solutions worldwide. ◆

With many years of experience in industries, processes, and applications PRUFTECHNIK offers innovative and customer-oriented solutions for maintenance and quality assurance. For more information, email usa@pruftechnik.com or visit www.pruftechnik.com.

____________________________________________

MODERN PUMPING TODAY, July 2017

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!

![]()