One of the most common problems lift stations/collection pits encounter is how to eliminate floating grease mats. If left unattended, the layer will continue to thicken until, eventually, a vacuum truck is required to suck out the mat. Over time, the frequent vacuum truck calls can result in thousands of dollars of maintenance and dumping fees. Alternatively, the proper solids-handling pump system can bypass the frequent service calls and contribute to a more cost-efficient lift station.

While most pumps in today’s market will effectively pump fluid, inputting the variable of debris, thickened sludge, and other solids into the mix drastically hinders the ability of those pumps to do their job. Furthermore, unclogging those pumps can be expensive and some pumps can even cost upward of $350,000 to replace if they clog beyond repair. The Conditioning Pump was created to help resolve this problem at a fraction of the cost.

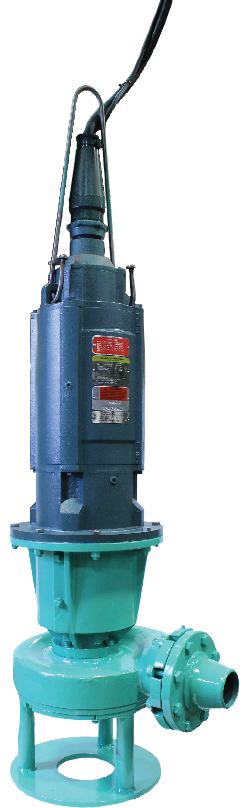

A Conditioning Pump is a submersible chopper pump that is designed by Vaughan Company to be used in several different scenarios to save on costly clean out cycles and maintenance. Conditioning pumps are mounted on a portable stand and fitted with a high-velocity mixing nozzle to recirculate the contents of a wet well. The Conditioning Pump can be placed directly in the wet well to chew up all of the rags and solids so that the existing pump won’t get clogged. Floating mats are removed and solids that have accumulated on the floor are re-suspended. As the pump is mounted on a portable stand it can easily be used in multiple applications at a single job-site, facility, or municipality.

Recently, the Otay River Pump Station (ORPS) in San Diego, California, had a problem in the large 50-feet long x 10-feet wide x 30-feet deep wet well. A floating blanket of grease and debris, sometimes as thick as 4 feet, would occur on a regular basis. The City of San Diego had been contracting two vacuum trucks to clean out the station every three to four months at a cost of approximately $50,000-$100,000 per year. As the city previously had a good experience with Vaughan Chopper pumps, they turned once again to Vaughan Company for a more cost-effective solution.

For ORPS, an 8-inch Submersible Chopper Pump with a 25 horsepower, 1,200 rpm motor, mixing nozzle and portable stand. In eighteen months of use with the Vaughan Conditioning pump, the wet well has not required cleaning. Based on the cost of the pump and installation the pump paid for itself in two and a half months of use.

For more information on Conditioning Pumps, visit www.chopperpumps.com or visit us at WEFTEC Booth #1017.