VAF Filtration Systems, based in Arvada, Colorado, addressed the challenge of providing a small footprint, cost-effective filtration solution to replace an outdated filter system head-on with Canadian-based Irving Tissue of Dieppe, New Brunswick. An outdated carbon steel filter system had outlived its usefulness and was in need of retrofitting and/or replacement. Faced with an obsolescence of existing parts, combined with the need for a simpler and more efficient design, the choice was clear: it was time to replace. VAF’s patented V-1500, 316L stainless steel filters with custom 316 stainless steel manifold, provided the ideal solution.

Teaming up with their Canadian distributor, Newterra, VAF supplied a state-of-the-art filtration package, while Newterra’s controller group brought their expertise to design a custom PLC control package that interfaced with the Irving Tissue maintenance control system. Newterra also provides on-site training and service to support the plant.

A SPECIAL DELIVERY

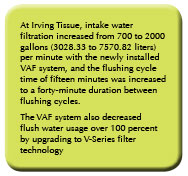

“It’s a first-rate system and looks great,” says Trevor Downey, project manager for Irving Tissue. Delivered and installed in ten weeks, the totally new stainless steel system replaces the old system. Using American made, patented mechanical barrier screen filtration with a flushing volume of less than 1 percent of the total flow, the new system substantially reduced the flushing volume: something the competition could not provide.

With the updated system in place, Irving Tissue also realized a reduction in its ecological footprint. “Optimizing water usage, increasing productivity, and identifying and analyzing the cost-benefits of an integrated system is what we do,” says VAF vice president Steve Springer.

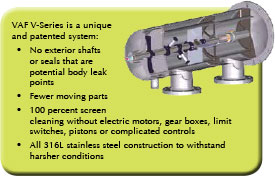

“We chose VAF for our site for several reasons,” Downey continues. “It was the most effective system solution with the least amount of moving parts. And the follow-up from VAF has been great—they really back up their product.”

IMPORTANT QUESTIONS

Similar to Irving Tissue, VAF can help decide when a system solution is a viable option:

- Is your current system more than ten years old; even five years old?

- How efficient and effective is your current filtration?

- Are your maintenance costs out of line each year?

- Would you like to deal with an American manufacturer?

- Can you afford not to replace now rather than later?

EFFICIENT SOLUTIONS

Filters and filtration systems over ten years old may not be meeting the level of filtration required to achieve your highest ROI. Furthermore, the efficiency of newer systems includes continuous filtration and near zero water waste. Replacing a current system rather than configuring your existing one may require less in maintenance, electrical costs, and with fewer parts, less in added training costs. Irving Tissue examined all of these and chose VAF for a cutting edge, state-of-the art design.

VAF’s unique and advanced systems include individual, manifolded, and skid-mounted automatic self-cleaning filtration systems all manufactured in the United States. The VAF V-Series filters can remove suspended solids from 1500 to 10 micron; and the cleaning cycle takes less than fifteen seconds with no interruption of flow or the filtration process. Instrumental in providing various types of pre-filtration, including, but not limited to, RO, UV, cartridge, membrane and other micro-filtration technologies, VAF provides both individual filters and pre-assembled systems to meet any flow demand. ■

FOR MORE INFORMATION

For thirty years VAF Filtration Systems has been providing filtration solutions worldwide with a business model built on simplicity, quality, and integrity. VAF filters qualify for LEED and ARRA funding—as all materials, manufacturing, and assembly are done in the United States. For more information, call 303.425.4242, email sales@vafusa.com, or visit www.vafusa.com.

MODERN PUMPING TODAY, July 2014

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!®