There are philosophical choices that have sparked some of the great debates of our time: Star Wars or Star Trek? Thin crust or deep dish? In the world of truck transport of liquid commodities such as motor fuels, heating oil and chemicals, the question that typically divides people into two distinct camps is “repair or replace?” Or more to the point, what is the best pumping technology with which to outfit your transport vehicles, one that can be repaired in the field, or one that should just be scrapped and replaced with a new model once it fails?

While both sides have their strong points—that is, after all, what makes for a good argument—the feeling here is that there is one solution that stands above the rest: Outfitting your truck fleet with sliding vane pumps featuring components that can be quickly, confidently and cost-effectively replaced in the field with no unnecessary vehicle downtime.

SURVEYING THE FIELD

The operators of transport-truck fleets have a basic choice of three customary truck-mounted pump technologies: the aforementioned sliding vane, along with external gear and centrifugal. Let’s take a closer look at all three technologies:

External Gear

This pump technology uses the meshing of gears to facilitate the flow of liquid through the pump at consistent volumes, which makes them a positive displacement (PD) pumping technology. They will deliver a constant amount of liquid with each revolution of the gears, while their tight clearances and speed of rotation restrict any fluid from moving backward, or “slipping,” during their operation. Since the gears are rigid, the pumps create a smooth, pulse-free flow, but also one that can handle very high pumping pressures, especially those that are needed to transfer high-viscosity liquids. However, the contact inherent in the meshing of the gears will cause them to wear over time. This wearing of the gears will compromise volumetric consistency and increase the risk that product slip will occur as the pump ages, which will result in decreased productivity over time. External gear pumps are also generally inexpensive, though they do have a relatively high number of wear parts, which will prompt many of their users to run them to failure and then replace, rather than repair, them. The cost to replace the wear items is a substantial percentage of the entire cost of the pump and directs users to scrap the entire pump for common wear.

Centrifugal

This technology uses the rotational energy created by an internal impeller to “throw” the liquid to the discharge port. Although less efficient than PD pumps (meaning they require more energy to perform the same amount of work) this method of operation produces a smooth, pulse-free flow. Conversely, to achieve this effect and the resulting operational benefits, by design centrifugal pumps are more complex, which means higher downtime and maintenance costs when they fail. Centrifugal pumps also tend to have a steeper purchase price, which can put the operator between a rock and a hard place when considering the repair-or-replace question. From an operational standpoint, while some manufacturers claim they are self-priming, most centrifugal pump models cannot prime unless they are first pre-primed. Also, they do not have the capability to fully deplete tanks during unloading, cannot strip lines for product recovery and spill reduction, and cannot run in reverse for recovery between loads. Lastly, centrifugal pumps must operate at a speed that requires either a hydraulic-drive system or a gearbox to convert typical PTO speeds to the required pump speed.

Sliding Vane

This PD-pump technology features a rotor with retractable vanes that protrude and retract as the rotor turns. This setup draws liquid into chambers that are created by the spaces between the vanes, from where it is pushed to the discharge port. The self-adjusting vanes sustain the pump’s volumetric performance, making it energy efficient while simultaneously preventing product slip. Another feature of sliding vane pumps is a lack of metal-to-metal contact, which reduces the possibility that pump friction and galling will occur. An additional sliding vane attribute is its self-priming ability and suction-lift capabilities, which allows the creation of an internal vacuum that is strong enough to strip lines and tanks. Since there is no metal-on-metal contact inside the pump, sliding vane pumps have a liquid-handling range from ultra-thin liquids (0.2 cP) all the way up to liquids with a thickness of as much as 22,500 cP.

At this point, it makes sense to acknowledge that not all sliding vane pump technologies (the same goes for external gear and centrifugal) are created equal. Knockoff models have entered the market that may look the same as a high-end sliding vane pump (while costing less), but their performance leaves a lot to be desired. Mainly, their components (vanes, shafts, bearings, seals, etc.) fail quicker during normal operation. Because of their reduced purchase cost, these sliding vane pump models will more likely than not be run to failure and then replaced, rather than repaired.

CONSIDERING THE VARIABLES

Taking all of this into account, we recommend that the best choice for truck transport of liquid commodities is a premium, precision-engineered sliding vane pump that can be quickly and confidently repaired without the need to remove the pump from the truck or ship it off to a service provider for the installation of replacement parts or general maintenance.

Before making that final decision, though, there are a few variables that must be considered. The first may be the most obvious—purchase price. On principal, a pump that is designed to be repaired will have a higher purchase price than throwaway technologies. Therefore, the developers and manufacturers of pumps that are designed to be repaired take great pains to make the purchase price as palatable as possible, knowing that any excess upfront costs—while potentially off-putting to the buyer—can be recouped on the back end via longer service life and more manageable and bottom-line-friendly repair costs.

For example, it’s a fact of life that a sliding vane pump is more expensive to buy than a competitive truck-mounted external gear pump. Still, if that vane pump can be placed on a truck and only needs to be repaired two or three times over twenty years of service, while the external gear pump needs to be replaced three or four times in that time span, the higher upfront purchase cost is more than worth it.

Secondly, even those fleet operators who prefer to repair their external gear or centrifugal pumps when required can be better served by choosing sliding vane technology. That’s because sliding vane pumps have only one major sacrificial component: the plastic vanes that will wear down over time, and when the day for replacement comes, the worn vanes can be swapped out for new ones in a matter of minutes without having to remove the pump from the truck. The pump’s other wear components—gaskets, O-rings, seals, bearings, etc.—can also be replaced quickly and easily without taking the truck out of service.

External gear pumps have more wear parts that will need to be repaired or replaced. The quandary that arises here is found in the fact that while the user may replace a worn or broken part, there is no way to know when any of the other wear parts in the pump will fail—it could be in two years or two days. In other words, the more components in the pump that will eventually need to be repaired or replaced, the better the chance something will break at the most inopportune time possible.

Complicated or reoccurring component repair or replacement also brings the potential for a large amount of ancillary costs to be incurred by the fleet owner. The more complicated the pump and its drive system, the less likely that fleet operators—which are quite often lean three to four truck operations with small staffs—will have the expertise on hand to perform repairs or preventive maintenance. In this case, an outside service provider will need to be scheduled, or the pump shipped out for repairs, which can mean excessive idle time for the truck, along with significant labor costs.

All of this sounds like an argument to simply replace the failed pump with a new one, but that returns us to the first consideration of purchase cost, acknowledging again that initial cost may be lower, but over the twenty-year life cycle of a high-quality sliding vane pump, an external gear or centrifugal pump need to be replaced three or four times.

The reliability of premium sliding vane pumps also allows their manufacturers to confidently offer best-in-class warranties and performance guarantees. In fact, one of the industry’s top sliding vane manufacturers offers a five-year warranty for its truck pumps, along with a two-year performance-assurance guarantee, meaning that if any part fails in the first two years of operation, it will be replaced, no questions asked.

CONCLUSION

In general, many people take a sense of pride in keeping a piece of mechanical equipment operating over an extended period of time. Sure, that snow blower may be 30 years old, but by taking care of the impeller, it hasn’t failed yet. Or there are instances of fuel-oil suppliers who will re-chassis their transport trucks but install their ten-year-old sliding vane pump on the new chassis. Sliding vane pumps have become the standard for efficient, reliable and cost-effective performance for liquid-handling on transport trucks—and their ease of part repair should put an end to the old repair-or-replace argument: Repair in a knockout!

FOR MORE INFORMATION

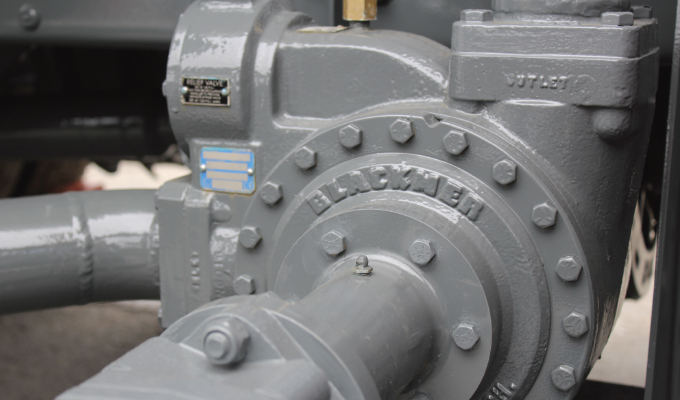

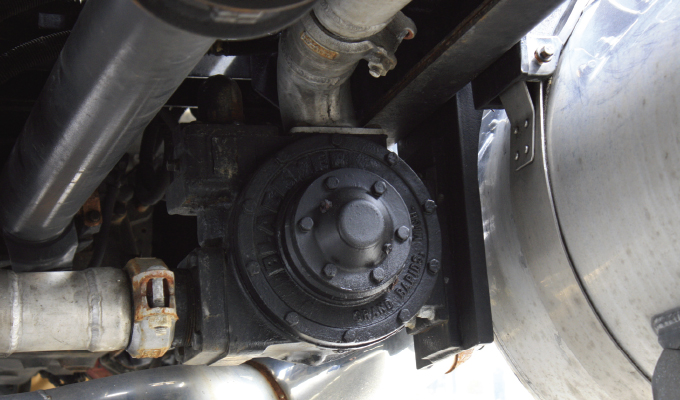

Chris Hordyk is a product manager for Blackmer®. He can be reached at chris.hordyk@psgdover.com. Blackmer is the leading global brand of sliding vane, gear, regenerative turbine, and centrifugal pump, and reciprocating compressor technologies for the transfer of liquids and gases. Blackmer is a product brand of PSG®, a Dover company. PSG is the global pump, metering and dispensing-solution expert, enabling the safe and efficient transfer of critical and valuable fluids that require optimal performance and reliability in applications where it matters most. PSG products are manufactured in state-of-the-art facilities that practice lean manufacturing and are ISO-certified. PSG is part of the Pumps & Process Solutions segment of Dover Corporation. For more information, visit www.psgdover.com/blackmer.

MODERN PUMPING TODAY, January 2024

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!