Meter users who have sought a reliable tool for continuous level measurement of liquids and solids have a new option from Krohne, Inc., who now produces a wide range of level products at its Peabody, Massachusetts, facility, and can offer a ten-day lead time for its most popular level products, as well as enhanced sales and service capabilities.

ANSWERING CUSTOMERS’ NEEDS

After a major investment in tooling and inventory, and the addition of production personnel, Krohne now provides made-in-the-USA convenience for the Optiflex 1100 C time domain reflectometry (TDR) level instrument for low cost or OEM type applications; the Optiflex 2200 C/F TDR for process industries with high pressure or high temperature applications; and the Optiwave 5200 C/F frequency-modulated continuous-wave (FMCW) radar level meter for liquid applications.

COST EFFECTIVE AND INTUITIVE

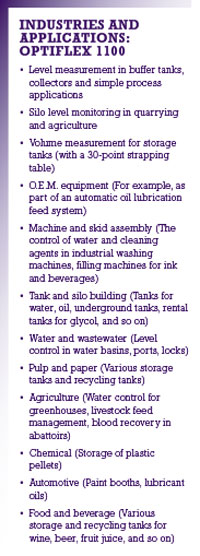

The Optiflex 1100 C TDR level instrument, a cost-effective two-wire loop-powered TDR level meter especially designed for continuous level measurement of liquids and solids, has an intuitive five-step quick setup procedure featuring easy menu navigation without opening the housing. With a measuring range up to 65.6 feet (20 meters) for liquids, and 32.8 feet (10 meters) for solids, this model works well for process temperatures up to 212 degrees Fahrenheit (100 degrees Celsius) and pressures up to 16 bar(g) /232 pounds per square inch gage (psig). All probes and process connections are made of stainless steel.

ELIMINATING FALSE REFLECTIONS

The Optiflex 2200 C/F level meter for liquids and solids features software-based dynamic parasite rejection (DPR) technology, which eliminates false reflections caused by environmental disturbances and product build-up. The two-wire device is the newest addition to Krohne’s guided radar level meters. This model is a cost-effective device for tank and silo applications in the chemical industry, as well as in the oil and gas, energy, waste water, mining or pulp and paper sectors. It is ideal for replacing traditional level meters that require higher maintenance, including displacer, RF capacitance, conductive and pressure level meters. The Optiflex 2200 C/F has been designed and developed for use in SIL 2 safety-related systems, in accordance with IEC 61508 functional safety requirements.

Also now made in the USA is the Optiwave 5200 C/F, a new 10 GHz FMCW radar level meter for liquid applications in up to a 98 foot (30 meter) measuring range. The cost effective two-wire loop powered device measures level and volume in storage or process tanks with process conditions up to 482 degrees Fahrenheit (250 degrees Celsius) and pressures up to 40 bar/580 psi. The Optiwave 5200 C/F also meets IEC 61508 requirements for safety-related systems. ◆

Sandy Olley can be reached at 800.356.9464 or s.olley@krohne-inc.com. Krohne is a worldwide technological leader in the development, manufacture and distribution of accurate, reliable and cost-effective measuring instruments for the process industries. For more information, call 800.FLOWING or 978.535.6060 in Massachusetts, email info@KROHNE.com, or visit www.us.krohne.com.

____________________________________________

MODERN PUMPING TODAY, July 2015

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!

![]()