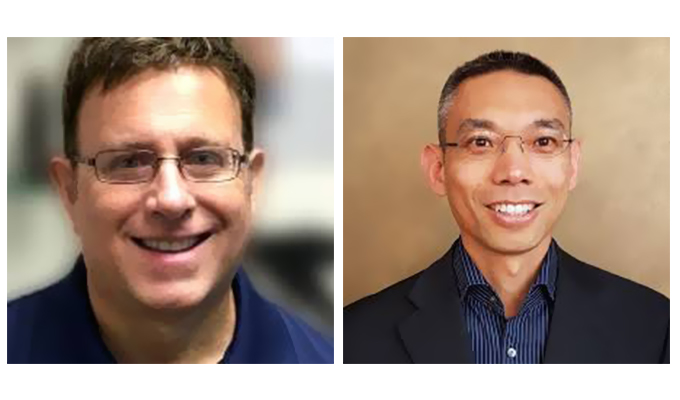

The use of real-time data has become a major leap forward in both efficiency and management decisions. Jim O’Rourke is an academic principal with OSIsoft and, along with his coauthor Dr. Osvaldo Bascur, has recently released the book “Digital Transformation for the Process Industries: A Roadmap,” which provides readers with a blueprint to digitally transform their facilities and entire enterprises. He and Gary Wong, OSIsoft’s industry principal for water, recently joined MPT’s podcast to discuss this technology’s bright future. An excerpt of that conversation appears below.

MPT: What are some of the ways industries can effectively integrate operational technology with information technology to become more predictive?

Jim O’Rourke:The first thing that any company that wants to go through its digital transformation and become more efficient, it is to consolidate their operations, data, all of it into a system of record that people in the enterprise, whether it be operations people, subject management, or subject matter experts like maintenance and process and safety. And all those people can have the data at their fingertips the way they want to consume it, to make sure their assets are running at peak performance, make sure that they’re running sustainably, and make sure that that safety is enabled. And then really to minimize controllable costs, whether that be any off-spec product, you make unscheduled downtime because equipment not performing the way it was supposed to, or simply just wasted energy because the process or the equipment is inefficient.

MPT: What are some of the more creative ways you’ve seen companies use real-time data infrastructure to improve their performance?

Gary Wong: I would say in the early days of the twenty-first century, the paper business went through a pretty traumatic downturn, as communications went from paper to electronic communication. And for so many of these paper mills, the demand went way down; however, they had their own ways of making power. So they said, “Well, how about if we sell this excess power back to the grid to have another revenue stream?” With the data that they had in the plant of the operations when things were scheduled, how much power was being used, then they could focus on selling excess power back to the grid and increasing the revenue streams.

MPT: In many cases, that raw sensor data was already there, so how has OT become more useful and adaptable in modern infrastructure?

Gary Wong: Yeah, when you hear about “big data,” for example, like before that was coined, all these automation and SCADA systems have been, like you say, generating a lot of data from the OT side of things. So having that context available is critical, and in terms of how, for example, we have templates set up, and we’ve got some customers, say Water Corporation in Australia, they’ve got over 1,000 pumping stations. They can easily create a single template for all these various pumps. And as that raw data comes in, context is automatically put beside it, in terms of the type, the location, the manufacturer, when it was last serviced, and so on.

Jim O’Rourke:Gary’s right on the money there regarding the sensor data. What our approach has been for many years is to contextualize the data as it’s collected. And more importantly, we have tools that can send this data with the context up to corporate analytics, and also the data scientists so that they can use it quicker and decrease time to value for their findings.

To listen to an extended version of this interview, be sure to subscribe to MPT’s podcast, The Efficiency Point.

MODERN PUMPING TODAY, March 2021

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!