In the previous installments of this series, we’ve taken a thorough look at how Efficiency Islands mark the improvements in a centrifugal pump’s operating performance—both via the component and system perspectives. In this concluding section, we will examine control curves and variable speed operation, as well as an operating cost comparison for the three test cases introduced in the previous article. These comparisons offer a detailed look at the benefits Efficiency Islands bring to the bottom line.

CONTROL CURVES AND VARIABLE SPEED OPERATION

Previously, the aspect of the control area has been reviewed (see figure 3 in part 1 of this series). This indicates the variations which pumps in HVAC systems must operate. When the aspect of Efficiency Islands is paired with the control area, it becomes evident the best, most efficient operation will result from variable speed operation. The width and depth of the Efficiency Islands of Product A address the type of systems encountered in the HVAC industry; however, even with a variable speed drive, pump selection relative to BEP can impact the overall system efficiency. Examples of two selections – one to the left of BEP and one to the right of BEP – illustrate this consideration.

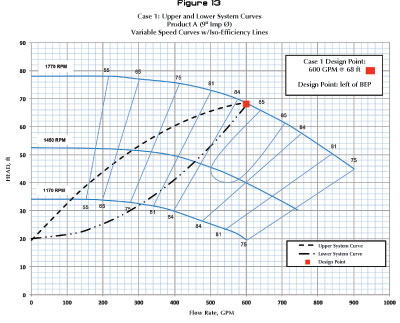

Figure 13 illustrates the historical, traditional pump selection with the design point to the left of BEP. While it offers meaningful operating cost savings through variable speed operation, there are opportunities for improvement. As operation occurs at the many load conditions from the design point down to very low loads, the pump efficiency will always decrease.

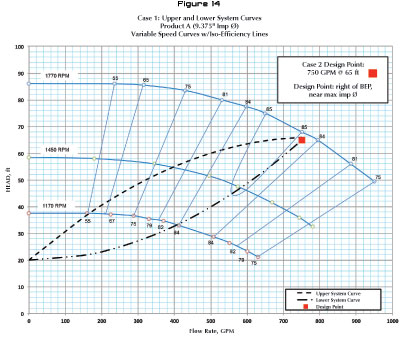

The next example in figure 14 shows a pump selected with the design point to the right of BEP. As can be noted when the pump operates at load conditions below design, the pump moves back through the higher Efficiency Islands. This yields a more economical operating system throughout the load profile.

OPERATING COST COMPARISONS

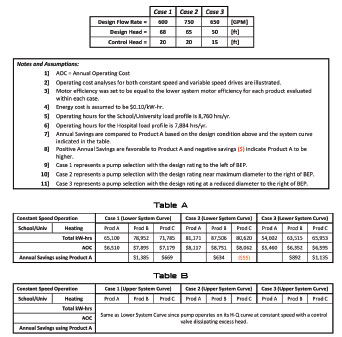

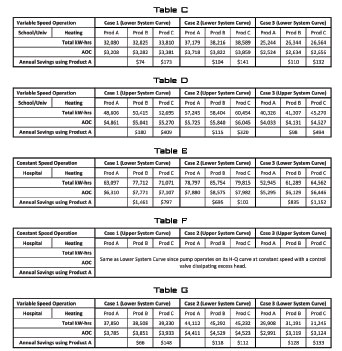

Some examples follow which illustrate the results one can see using modern design enhancements with the resulting advantages of the Efficiency Islands. Three cases are illustrated with operating costs tabulated for Products A, B, and C.

An example of the cost analysis for Table H is provided in Table I. This provides the data for Products A, B, and C for variable speed operation for the hospital heating profile for Case 1 (Upper System Curve) in Table H.

OPERATING COST ANALYSES SUMMARY

Constant Speed Operation

In virtually all cases for the system loads evaluated, there are prominent annual cost savings using Product A versus Products B and C. Power savings realized with Product A are typically in the 10 to 20 percent range when operating at constant speed.

Variable Speed Operation

There are annual savings accrued utilizing Product A in virtually all situations compared to the competition with variable speed operation. The savings attributed to the gain in pump efficiency are much lower in magnitude compared to constant speed operation. This can be explained, in part, by the fact that variable speed operation reduces the power needed to much lower values than constant speed operation. At the lower power requirements for variable speed operation, the differences in power savings do not generate as much dollar cost savings although the changes are meaningful from a percentage basis. Savings are typically in the 3 to 6 percent range when comparing variable speed operation. Also caution must be used since variable speed operation can occur within the control zone region bounded by the upper and lower system curves. It is not good practice from an evaluation standpoint to assume all operation will occur on the traditional, lower system head curve.

When variable speed drives are considered, the most advantageous operating efficiency will be obtained when the design point is selected to the right of BEP. Product A also provides for situations when reduced impeller diameters can be selected to satisfy a driver non-overload requirement with VFD situations.

Summary Analysis

Design enhancements which yield enhanced Efficiency Islands provide multiple advantages for engineers and users. Recognizing the wide variation in flow and pressure demands of HVAC systems should place additional emphasis on the capability of pump units to meet these varying conditions while sustaining efficient operation. The large majority of the Product A sizes will yield results similar to those presented in this comparison. Knowledge of heating, cooling and water supply systems by the centrifugal pump supplier organization and sales network, enables combined system and pump expertise to come to the forefront. This ensures practical design solutions for systems and pumps providing long term, cost effective operation.

Let’s review results from this effort. Whenever possible there has been focus on the HI POR for pump selection. Coupling this with variable speed operation provides many benefits, including:

- Higher operating efficiencies

- Lower mechanical loads on the shaft and bearings

- Longer mechanical seal life

- Lower vibration levels

- Lower noise levels.

Comparison of Product A efficiency performance to Products B and C from several perspectives illustrates the meaning and results obtained from the improved Efficiency Islands of Product A.

THE POWER (AND ADVANTAGE) OF E

How do the improved characteristics of Product A that result in larger Efficiency Islands translate to advantages for the customer?

- When comparing constant speed operating units, lower operating costs will predominantly result.

- When pump and driver sizes are compared, there will be occasions when smaller pumps and/or smaller drive sizes can be used.

- Sustaining efficiency levels at reduced impeller diameters can allow non-overloading motor sizes to be limited with variable speed drives when at maximum speed.

- While not directly compared in this discussion, variable speed units offer significant annual operating cost savings when compared to fixed speed units for the same service conditions. Additional benefits relating to maintenance and operational flexibility result when comparing a variable speed drive versus a fixed speed unit.

- When variable speed units are compared, operating cost savings will not be as dramatic as comparing fixed speed units, but when savings are indicated it leads to an overall, more efficient pump operation. This yields the best balance of operating cost and flexibility from energy, operational and maintenance perspectives.

- Especially with variable speed drives, consider selecting pumps with the design point to the right of BEP. This allows operation at reduced loads to move back through the most efficient pump range rather than continue to move away from the most efficient range when a pump is selected to the left of BEP.

NOTES

ASHRAE 90.1 – 2010 Energy Standard for Buildings

ANSI/Hydraulic Institute Standard 9.6.3 – 2012, Guideline for Allowable Operating Region

Simplified Analysis of Flow in Closed Loop Hydronic Systems, Bell & Gossett Technical Brochure TEH-802P, August 2001

Variable Primary Flow Systems, Bell & Gossett Technical Brochure TEH-910, 2010

ABOUT THE AUTHOR

Christopher S. Johnson is the global engineering manager for centrifugal pumps in Xylem Applied Water Systems in the commercial building and HVAC business unit, while also supporting the other business units with crossover products. He has held leadership roles in sales, application engineering, product management, global sourcing, global product development, and engineering.

_______________________________________________________________________

MODERN PUMPING TODAY, MARCH 2014

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!