As we introduced in part 1 of this article last month, the potential of Single Pair Ethernet (SPE) is huge and experts consider it to be the next generation of communication architecture in automation. Originally developed for automotive applications, it promises nothing less than a continuous connection from the sensor to the cloud. And this is the case in practically every application, whether in industry, logistics, buildings, or wherever data is generated. The concept behind it is essentially an extension of the Ethernet to the sensor, that is wherever “tracks” (in the literal sense) rather than data highways are needed in every inch of space within the plant—it is compact, flexible, and offers extensive reach.

This explains why there is such a high level of interest in standards across all industries and why the standardization process is well underway. Naturally, at this stage of the process, some manufacturers tend to communicate proposals as regulations without further ado in order to issue their product as a new standard.

THE CONNECTOR IS THE FIRST STEP

Weidmüller supports connector development for the IEC 63171-2 variant for IP20 environments and the IEC 63171-5 variant for IP67 environments. With a focus on cross-sections in the range AWG 26—AWG 22, an extremely user-friendly portfolio can be established—with M8 connectors for plugs and sockets. This applies both to free connectors on the cable as well as the fixed variant on the housing. This means there is no need for extension cables that only have plugs or sockets at both ends. This is essential for PoDL especially, as the live side must always be designed as a socket. A third advantage of this solution is the significantly improved HF performance compared with competitor products, which means that the cabling will also meet even higher performance demands in the future.

A further advantage of the solution is that the connection systems in accordance with IEC 631712 (IP20 environment) and IEC 63171-5 (IP-67 environment) have the same mating face. Both can therefore be freely combined. This compatibility is most beneficial in field measurement technology. Furthermore, the mating face can also be used independently of any application, from the workstation through computing centers and industrial cabling and to the cloud.

On this basis, the developers have established the key properties for SPE connectors used at machine level in order to satisfy all forms of industrial application. Initially the product range is wide, although this does not mean a plethora of different components, but rather components that are as versatile as possible to use. This includes the above mating face that is the same for IP20 and IP67 environments. This limits the number of components without reducing the application possibilities, which is advantageous in warehousing. The mating face naturally needs to be available as a free connector and also on the device side as both male and female. PoDL and daisy chaining are thus supported, as was already typical for devices with M12/M8 connectors. This also includes straight and angled variants with and without LED for IP20 printer circuit board connectors; as well as continuous IP67 cabling on the basis of M8/M12 connectors.

A further point is unrestricted industry suitability, which includes a robust locking mechanism as is the case with RJ45 connectors. The pull-out force is at least 50 N. Also, all components should also be easy to assemble in the field. Typical key technical data defined were cabling in the AWG 26—AWG 22 range, an industrial dielectric strength of 2.25 kV DC and a permissible pollution degree of 2 on the printed circuit board. The electrical and mechanical connection must also be guaranteed in extreme applications at machine level. A Flexion Test in accordance with IEC 60998-2-X provides evidence for this. As part of this test, not only is the cable tested for axial strain, it is also loaded vertically. This simulates the loads that the cable is subjected to on a robotic arm, for example

As there is virtually no space for cabling in many Industry 4.0 applications, the design must remain compact. With a pitch of 7.62 millimeters, this version is just half the size of an RJ45 connector. This means that two Single Pair Ethernet ports can be installed in the space occupied by an RJ45 PCB connector, doubling the port density. These points go together as they ensure flexibility in terms of faster transfer rates in further development and also enable existing installations to be expanded. The connector therefore offers investment security in all respects.

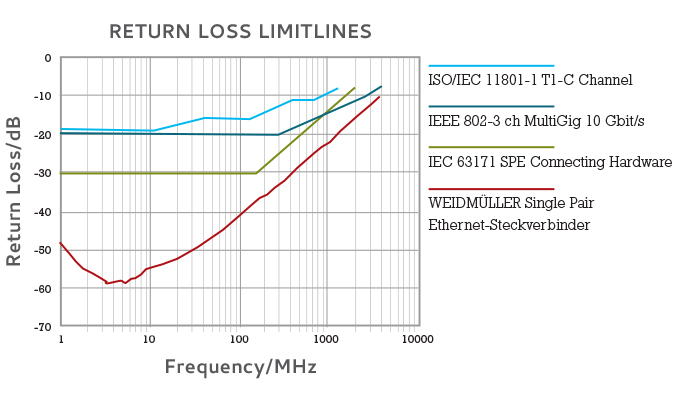

This is guaranteed through aspects including high TCL (transverse conversion loss) as well as good RL (return loss). The return loss describes the impedance behavior between the connector and the socket. A high return loss ensures optimal data transfer to the interface. The TCL describes the connector symmetry. Optimal symmetry minimizes external interference and is therefore an important characteristic for robust industrial environments. The connector is also suitable for use in multi-gig applications (2.5, 5, 10 gigabit), as it is designed for data transfer rates of up to 4.0 GHz. This mating face thus provides a solution for transfer rates of 10 megabit to 10 gigabit, from the sensor to the cloud.

GREATER FLEXIBILITY WITH A FOUR-CHAMBER SOLUTION

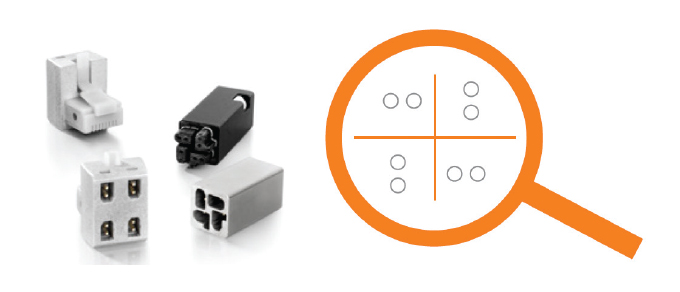

Besides the connector for a single cable as described above, Weidmüller is also planning to bring a four-chamber version onto the market that can be used to achieve four SPE cablings via one interface (cable sharing). The arrangement of contacts allows for ideal electrical properties. The contact pairs are arranged perpendicular to each other and minimize interference between the individual cables. The additional shielded cross reduces the remaining interference.

Thanks to this extremely compact design, four Single Pair Ethernet ports are possible in the installation space of an RJ45 connector. A typical application would be a welding robot with closely spaced sensors at the far end of the arm. These can be connected without the need for an additional switch or via trunk cable. This kind of bundled structure is difficult to implement using other connection technologies.

Due to the increased demand for these connectors in category 8.2 in accordance with ISO/IEC 11801-1:2017-12, the four-paired connection technologies can be used in accordance with IEC 63171-2 and IEC 63171-5, independently of any application. Computing centers, offices, homes and industry are equally conceivable areas of use. With these features, the SPE solution from Weidmüller offers perspectives that go beyond those generally required in industry. The offering will be completed with active components in the future, meaning that the user will have a complete SPE infrastructure from a single source.

THE RIGHT CABLE

Standardization also deals with cabling of course. Manufacturers are currently developing lighter, thinner, and more cost-effective cables that allow more Ethernet channels in existing cable runs, while supporting PoDL and enabling data and power to be transferred over distances greater than 3,000 feet. They are also distinguished by broader bandwidth and robustness to electromagnetic interference. In the future, this will enable a cabling and network standard that can communicate with each sensor or actuator while supplying it with power. Just like the connectors, the cables also need to be robust enough for industrial use. Typical examples include a smaller bending radius for installations where there is a shortage of space as well as the flexion test previously mentioned.

IMPULSES FROM THE AUTOMOTIVE INDUSTRY

To conclude, let us take a look at the latest developments from the automotive industry, the original initiator of SPE. This sector is also driving forward standardization. Ethernet systems are being increasingly installed in the current vehicle generations. Further innovations in the areas of driver assistance systems, such as LIDAR (light detection and ranging, used for detecting objects), high-resolution displays, autonomous driving, 4K cameras, and infotainment can only be achieved by networking control units and sensors. The development of the automotive Ethernet has resulted in two official IEEE standards: 100BASE-T1 (100 megabits per second based on BroadR-Reach technology) and 1000BASE-T1 (1 gigabit per second).

Fundamentally, this was centered around defining limit values for the connector and cable components as well as associated measurement methods based upon the requirements of the entire channel that was defined in the IEEE standard.

HARDWARE FOR THE ETHERNET OF THE FUTURE

SPE will play a major role in many areas of communication architecture. It offers continuous, scalable, and deterministic networking from the sensor to the cloud. Thanks to PoDL, besides a data interface it also delivers power wherever it is needed, even where there is a severe shortage of space—provided that the cabling is suitably compact. Weidmüller has, therefore, developed a connector that is only half the size of an RJ45 connector and offers the same mating face for both the IP20 and the IP67 versions. It can be used from the workstation through to computer centers and machine-oriented sensors. This makes the Weidmüller solution the ideal tool for IoT and Industry 4.0 applications.

FOR MORE INFORMATION

Simon Seereiner is head of product management for sensor-actuator interface and industrial ethernet and cable harnessing. Since 2005, he is expanding the range of solutions for the passive, industrial networking of the Weidmüller Group. In addition, Seereiner works in various national and international committees for industrial networking. For more information, visit www.weidmueller.com.

MODERN PUMPING TODAY, January 2022

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!