No matter the size of your operation, you need to keep pumping stations running around the clock to push water or wastewater where it needs to go—no matter how far away they are from a well or plant. This means personnel must frequently monitor the status of environmental conditions and equipment. Because pumping station sites can be physically difficult to access on a regular basis, installing a remote monitoring system can save time, money and anxiety. Newer monitoring systems that use cloud-based technology let you see real-time status of all monitored conditions and receive alerts on your mobile device of potential problems.

Installing a monitoring system and sensors can be easier than you might think. Here are answers to ten questions to ask before installing a cloud-based monitoring system:

1. WHAT IS REQUIRED TO USE A REMOTE MONITORING SYSTEM?

Most remote monitoring systems require an internet or WiFi connection and access to an electrical outlet to power them. If you don’t have an internet connection at your location, you’ll want to choose a cellular system. You’ll have to register the cellular monitoring device on a wireless network before you can send or receive messages. Before purchasing a cellular device, you’ll want to make sure that there’s sufficient signal strength at your site.

2. HOW DO WE DETERMINE WHAT KIND OF MONITORING SYSTEM AND SENSORS WE NEED?

A reputable manufacturer will have a well-trained support team that can assess your needs even without a site visit to determine which products are best for your application. If you feel you need them to check out your water pumping operation, many companies can set up a video conference to substitute for being on site. Alternatively, the manufacturer may be able to recommend local contractors.

You will want to provide details about the scope of your water pumping operation. Then, work with the equipment provider to determine a system that fits seamlessly with your existing floats, pump alarm outputs, and level transducers for an easy installation. Ask about hard wiring, programming, software setup, and integration requirements. Many monitoring devices can easily interface with any equipment that is being controlled by a PLC. The device should be able to pull values from any MODBUS equipment or sensors and make that information available remotely. Users can set alarm limits on that data and receive alarms. In addition, the monitoring device can serve as a simple dial out for any PLC alarms that are already set up.

The monitoring system representative will then determine the type of system that would best serve your operation, the number of base units you will need, and the types of sensors required. Note that there shouldn’t be a cost for a demo, consultation, or assistance throughout the sales process. Be sure to ask if there are any fees or licenses to keep using the monitoring equipment after you purchase it.

3. ARE SENSORS INCLUDED WITH A MONITORING SYSTEM?

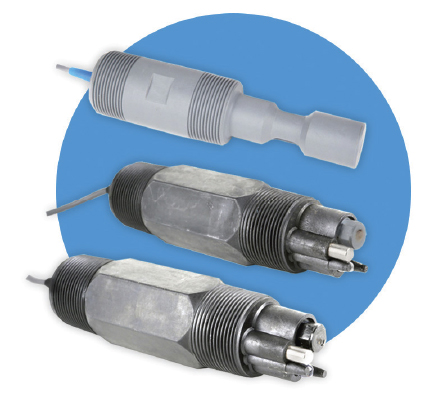

In most cases, sensors are sold separately. The sensors you select depend upon the conditions you want to monitor and how many you can connect to your base unit. Conditions you want to monitor include tank levels, pump status, flow rate, vibration, pressure, run times, and voltage.

Of course, your entire pumping operation relies on electrical power. Not only does a power outage monitoring sensor detect power failure, it also monitors equipment for conditions that predict if a problem is looming, such as power fluctuations that occur at specific times.

To monitor the physical security of your pump stations, you can add sensors to doors and windows. That way, you can remain vigilant and be alerted to any unauthorized entry into the facility, no matter how remote or what time of day.

4. DO MONITORING SYSTEMS ONLY WORK WITH THE MANUFACTURER’S SENSORS?

Not necessarily. For example, certain monitoring units can connect with most digital, analog, or MODBUS sensors and transmitters regardless of the brand. When selecting sensors, you might have a choice between ones that are designed by the manufacturer to work specifically with the monitoring system or universal components made by a third party. If the components aren’t made by the system manufacturer, you’ll want to find out if they have been tested with the monitor you are choosing and if you need to work with another vendor to purchase the parts.

5. DO WE NEED TO HIRE AN ELECTRICIAN TO HELP WITH INSTALLATION?

In general, monitoring systems are quick and easy to install, and users can often set them up without hiring an outside expert. However, installations at pump houses can be more involved than those at other facilities, and you might need the help of an electrical contractor depending on the conditions you are monitoring. If you’re monitoring conditions from an existing PLC, you may need to have the panel manufacturer review your plans.

Therefore, it’s best to have an electrical expert set up the system. If the manufacturer doesn’t offer installation services, ask if they can recommend a local representative in your area who can set up your system.

6. IS THERE A MONTHLY FEE TO ACCESS ALL THE FUNCTIONALITY OF A MONITORING DEVICE?

Many web- or cloud-based systems provide free functionality with some limitations. You might have to purchase a premium subscription to unlock features such as text messaging, phone call alerts, and unlimited data logging access. If your device is required to be on a cellular network, you should budget an annual subscription cost as well.

7. SHOULD WE GET A SYSTEM THAT IS WIRED OR WIRELESS? WILL WE NEED TO HAVE A PHONE LINE, CABLE, INTERNET, OR SOMETHING ELSE?

Wireless can mean two different things as it relates to monitoring: how the system communicates its data to the outside world and how the sensors communicate with the system.

As noted above, some monitoring systems require an internet or WiFi connection to communicate their data to users, but if that’s not an option, cellular systems are available. Monitoring devices that use cellular communications must be registered with a wireless network provider. Landline phone-based systems are also available.

Sensors communicate with the base unit either through wires that connect them to the monitoring device, or wirelessly through built-in radio transmitters that communicate with the base unit. Some monitoring systems can accommodate a combination of hardwired and wireless sensors.

8. CAN ONE SYSTEM MONITOR SEVERAL SENSOR INPUTS AROUND THE CLOCK?

The number of sensors a base unit can monitor varies. Make sure to evaluate your needs and to select one that can accommodate your present situation and future growth. Once the monitoring system is installed and programmed, it will constantly read the information from the sensors 24/7.

If seeing the data in real time, rather than just a few times a day or on a delay, is important, then you’ll want to ask about that feature before you select your device. Cloud-based systems have data logging capabilities and store limitless amounts of information that you can view from any internet-connected device via a website or app.

If the system detects any sensor readings outside of the preset range, it immediately alerts people on your contact list. If you don’t want all your personnel to receive notifications at the same time, some devices can be programmed to send alerts in a tiered fashion or on a schedule.

Multiple communications methods like phone, email, and text provide extra assurance that you’ll get the alert. It’s a good idea to check the number of people the system can reach and if the system automatically cycles through the contact list until someone responds. Some systems allow for flexible scheduling, so that off-duty personnel don’t receive alerts.

9. DO MONITORING SYSTEMS HAVE A BACKUP POWER SYSTEM, SUCH AS A BATTERY, THAT WILL ENSURE THE ALARMING FUNCTION STILL WORKS IF THE POWER GOES OUT OR IF SOMEONE DISCONNECTS THE POWER?

The safest choice is a cloud-based system that comes with a built-in battery backup that will last for hours in the event of a power failure. Cloud-based units constantly communicate a signal to the cloud to validate their online status. If the communication link is interrupted—for example, by a power outage or an employee accidently switching off the unit—the system generates an alarm indicating that the internet connection is lost or that there is a cellular communications problem. Users are alerted about the disruption through phone, text, or email. All data collected during this time will be stored in the device and will be uploaded to the cloud when the internet connection is restored.

If you opt for a cloud-based monitoring system, make sure the infrastructure used to create the cloud platform is monitored 24/7 by the manufacturer’s team. Ask if they have multiple backups across the country to ensure the system is never down.

10. WHAT ARE THE COSTS ASSOCIATED WITH REPAIRS TO THE SYSTEM?

Purchase your system from a reputable manufacturer that provides a warranty and offers full repair services in the event the product stops working as it should. Also, research to make sure their tech support team is knowledgeable and willing to walk you through any questions you have about your monitoring system. Often, support specialists can diagnose and correct unit setup and programming issues over the phone.

It helps to record your observations regarding the problem, so the tech team can look for trends and circumstances concerning the issue and better diagnose the problem. Ideally, the manufacturer can provide loaner units if your problem requires mailing the device to their facility for repair.

As you can see, installing a monitoring system is an easy and affordable way to make sure your equipment is running properly and environmental conditions are where they need to be to keep the pumps working and water flowing.

FOR MORE INFORMATION

Siemens Digital Industries Software, a business unit of Siemens Digital Industries, is a leading global provider of software solutions to drive the digital transformation of industry, creating new opportunities for manufacturers to realize innovation. With headquarters in Plano, Texas, and over 140,000 customers worldwide, we work with companies of all sizes to transform the way ideas come to life, the way products are realized, and the way products and assets in operation are used and understood. For more information, visit www.sw.siemens.com.

Rob Fusco is director of business development with Sensaphone, a developer and manufacturer of remote monitoring and alerting systems. He can be reached at rfusco@sensaphone.com or 877.373.2700. For more information, visit www.sensaphone.com.

MODERN PUMPING TODAY, July 2019

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!