Introducing its Contactor and Recharger chambers to the industry in 1986, CULTEC helped begin a revolution toward using plastic construction products. Since then, several product developments and strategic alliances have made CULTEC a cutting-edge manufacturer focused on research and development. The company’s Contactor® and Recharger® plastic septic and stormwater chambers were designed to provide a lightweight stormwater management solution compared to heavier concrete structures. A wide variety of sizes ensure there is a chamber to meet virtually any installation requirement.

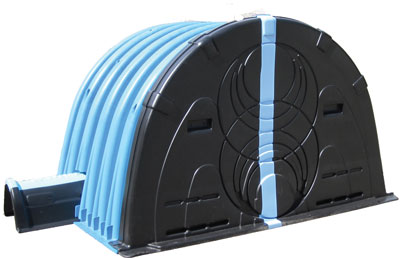

THE RECHARGER® 902HD

The newest chamber CULTEC provides to the stormwater market is also its largest offering yet—the Recharger® 902HD. This ultra-high capacity model offers the benefit of minimizing project costs by maximizing storage volume in a given footprint. The Recharger 902HD is an ideal solution for high-volume stormwater management systems due to its lightweight maneuverability, shipping and stockpiling benefits and design flexibility.

When compared to smaller, lower capacity chamber sizes or comparably sized large diameter pipe, clients achieve the required storage volume in a condensed footprint using the Recharger 902HD and require less labor and excavation, resulting in a lower cost per cubic foot. Additionally, the chamber’s shorter length and light weight (78 pounds [35 kilograms]) allow for easier handling and reduced heavy equipment time when judged against competitive models.

The Recharger 902HD is open on both ends and requires a separate end cap to cap chamber rows.

QUICK ASSEMBLY ON SITE

Units are shipped on pallets at twelve pieces-per-skid, fourteen skids-per-truckload and stockpile neatly on site in a compact area. The installing contractor and heavy equipment operator experience less downtime when receiving CULTEC Recharger 902HD material shipments than when waiting for several truckloads of heavy concrete structures or loose pipe to arrive and to be unloaded.

Chambers are joined using an overlapping rib connection. Each 902HD chamber includes CULTEC’s unique side portal feature which allows connections to take place at any point within the system for maximum design flexibility. Smaller chamber-type cross feeds called HVLV FC-24 Feed Connectors are inserted into the side portal openings to create an internal manifold. Having the manifold incorporated within the system reduces the required bed area and related excavation costs. A custom-fabricated external pipe manifold is eliminated by using this internal manifold feature.

GREATER STORAGE PER FOOT

The model has an installed length of 3.67 feet (1.12 meters) long, 78 inches (1981 millimeters) wide and 48 inches (1219 millimeters) tall. The bare chamber storage capacity of the Recharger 902HD is 17.66 cubic feet per foot (1.64 cubic meters per meter)—more than 20 percent greater storage per foot than the closest competitor chamber size. The chamber boasts a minimum installed storage of 27.27 cubic feet per foot (2.53 cubic meters per meter) when installed with stone. The Recharger 902HD shall be designed to withstand AASHTO HS-25 defined loads when installed according to CULTEC’s recommended installation instructions. The company currently offers the largest variety of chamber sizes ranging from 8.5 to 48 inches (216 to 1219 millimeters) high to fit almost any installation requirement. ◆

To support the engineering community, CULTEC is modeled in Bentley Systems’ PondPack V8i, HydroCAD, Autodesk Storm and Sanitary Analysis and Streamline Technologies’ ICPR and can assist with any design by performing preliminary calculations and supplying job-specific AutoCAD® layouts free of charge. A free Stormwater Management Design Guide is available upon request. For more information, call 203.775.4416 or visit www.cultec.com.

____________________________________________

MODERN PUMPING TODAY, June 2015

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!

![]()