Vesconite bushings, fitted in cooling water feed pumps at the largest New Zealand gas fired thermal power station, have significantly overcome problems caused by the interruption of process water which often resulted in serious bearing failure.

A RECIPE FOR FAILURE

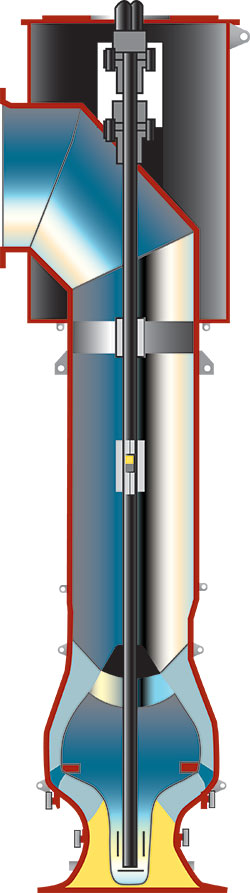

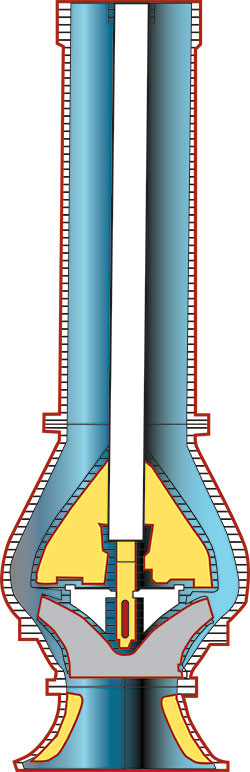

Originally the pumps, used for pumping sea water were fitted with rubber bushings.

The water supplied to the pumps is interrupted by sea weed blocking the inlets. The “no cooling water” alarm triggers when this happens but the pumps can run dry for up to forty-five seconds before they are stopped.

The rubber bushings often overheat and are severely damaged within thirty seconds, often before the alarm is triggered.

THE LIMITS OF RUBBER BUSHINGS

Rubber is an acceptable pump bushing material provided a stable supply of cooling water is available. This is, however, not always the case in practice as this case study demonstrates. The bushings may be dry at startup before the pumped water reaches them or they may run dry if the water flow is stopped due to blockages.

In their search for a solution, the power station first tried replacing the rubber bearings with an elastomeric material widely used for pump bearings. However, this material wore the expensive 316L stainless steel shafts. This proved more costly than the bearings, and was more difficult to repair and entailed additional downtime. The bushings were then replaced with Vesconite.

The pumps fitted with Vesconite bushings have overcome the problems associated with rubber bushings and dry start up. Vesconite bushings have outlasted the rubber bushings by far and have shown to be more shaft friendly than the previous materials that were used. The chief engineer is now committed to using Vesconite bearings for these pumps.

INTERNAL LUBRICATION IS CRUCIAL

The internal lubricants in Vesconite (and an even more advanced lubricant in Vesconite Hilube) make this an ideal material for pump bushings where there is the possibility of a dry start or an interrupted flow during operation.

The following dry running tests were conducted on Vesconite Hilube.

- Operating conditions are typical to pump bushings.

- Pressure P = 5.7 psi (0.4 kg/cm²)

- Surface velocity v = 1152 fpm (360 m/min)

- PV = 6566 psi.fpm (136 kg.m/min.cm²)

Vesconite Hilube survived these conditions for well over a full minute without damaging the bearing. With very low friction, it is a major advance, offering long wear life. It shows exceptionally low wear rates when lubricated, whether this occurs at fitting only or regularly.

BACKGROUND OF VESCONITE HILUBE

Developed to solve wear problems in unlubricated and dirty applications, Vesconite Hilube is a premium long life, low maintenance plain bearing material, which also gives outstanding performance when lubricated.

Vesconite Hilube is compounded from an advanced engineering thermoplastic incorporating a PTFE internal lubricant, so it has a very low dynamic friction (approaching that of PTFE) and an even lower static friction. The low static friction means no stick-slip problems in applications with intermittent motion.

Vesconite Hilube overcomes the limitations of metallic bearing materials and conventional engineering plastics. Vesconite Hilube combines a load bearing capacity higher than white metal with more than ten times the wear life of bronze in poorly lubricated or dirty conditions. Its self-lubricating properties are far superior to nylon. But unlike nylon based products, Vesconite Hilube does not swell in water or in humid conditions.

This is far better than alternative water lubricated pump bushing materials, many of which melt down or burn within seconds; 90 percent of dry start up specifications require only a one-minute running time.

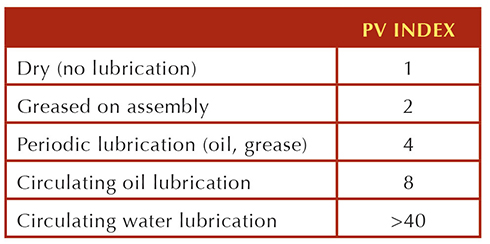

LOAD AND SPEED LIMITS

The product of load and bearing surface speed—commonly called the PV limit (pressure x velocity) is often given as a design guide. The PV limit of Vesconite Hilube is over four times that of nylon and twice that of Vesconite Standard. PV limits are usually determined in laboratories and are not always applicable to field applications.

Many factors affect PV limits, particularly lubrication, load and speed. For a given load, the bearing surface speed may be greatly increased with improved lubrication and cooling through circulation.

SAVINGS INTO THE FUTURE

At this power station, a further advantage noted is that the installed running clearance was much closer for the Vesconite bushings than was possible with the rubber bushings. The benefit is that the impeller does not run on the casing and therefore the pump is more efficient, both in respect of pumping ability and a saving in power consumption. ■

_________________________________________________________________________

ABOUT THE AUTHOR

Aitor Laso is gerneral manager at Rotork Controls Iberia, S.L. He can be reached at aitor.laso@rotork.com. For more information, visit www.rotork.com.

_________________________________________________________________________

MODERN PUMPING TODAY, June 2013

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!

![]()