In the first part of this article, we discussed some of the materials that have been tested extensively for use in diaphragms in AODD pumps—rubber, TPE (thermoplastic elastomer) and PTFE (Polytetrafluoroethylene or Teflon®)—with special attention given to rubber diaphragms. In this month’s installment, we will examine TPE and PTFE diaphragms and conclude by rating and comparing all three diaphragm materials for the properties and attributes that make them suitable for different applications.

THERMOPLASTIC ELASTOMER (TPE) DIAPHRAGMS

TPE diaphragms are manufactured by injection molding. As a result of their dimensional stability and tensile strength, TPE diaphragms do not need fabric reinforcement. Following are the available types of TPE diaphragms:

- Polyurethane is an outstanding general-purpose diaphragm for nonaggressive chemical applications such as water, wastewater and seawater. It provides excellent flex life, abrasion resistance and durability at an economical price.

- Wil-Flex™ provides a low-cost alternative to PTFE with a cost comparable to neoprene. Made of Santoprene™, Wil-Flex is ideal for use with acidic and caustic fluids such as sodium hydroxide, sulfuric acid or hydrochloric acid. Exhibiting excellent flex life, abrasion resistance, temperature range and durability, it is widely used in the chemical process, food, pharmaceutical and wastewater industries. Versions of Wil-Flex are available that comply with FDA 21 CFR 177 standards for food and beverage applications.

- Saniflex™ is an excellent material for food processing applications. Made of Hytrel®, it exhibits good flex life and excellent abrasion resistance. Hytrel also offers superior sealing or seal energizing due to its low compression set characteristics. Saniflex versions are available that comply with FDA 21 CFR 177 standards.

- Geolast® exhibits enhanced oil-resistance and low oil swell making it ideal for petroleum industry applications. Equivalent to nitrile (Buna-N), Geolast provides moderate flex life and good abrasion resistance over a wide temperature range at a lower cost than fabric-reinforced Buna-N.

POLYTETRAFLUOROETHYLENE (PTFE) DIAPHRAGMS

Because it is one of the most chemically inert compounds available, PTFE can be used with an extremely wide range of fluids. Also known as Teflon®, PTFE is excellent for highly aggressive fluids such as aromatic or chlorinated hydrocarbons, acids, caustics, ketones and acetates. Its properties provide excellent flex life and moderate abrasion resistance. In addition, PTFE complies with FDA 21 CFR 177 and USP Class VI standards for food, beverage and pharmaceutical applications. Because PTFE is non-elastic, a backup diaphragm of a different material must be used to provide flexibility and memory. Material options for backup diaphragms are Neoprene, Saniflex and high temperature Buna-N.

RATING AND COMPARING DIAPHRAGM MATERIALS

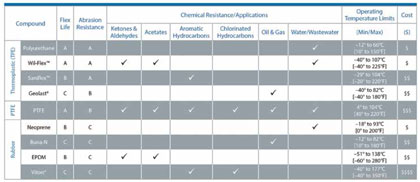

Using extensive material testing and field data, Wilden® compiled a that compares and rates the flex life, abrasion resistance, chemical resistance, temperature limits and relative cost of each material type. It is important to note that this chart should be used only as a guideline and in conjunction with thorough additional research and expert advice to determine the suitability of diaphragm materials for individual applications because one factor can affect another.

Correct diaphragm material selection for each application is critical to assure safe and efficient AODD pump operations.

When using the chart, always strive for an “A” or “B” rating and keep the application’s maximum fluid temperature as close to the center of the “Operating Temperature Limits” as possible. The selection of “C” -rated materials is generally not recommended but may be necessary in rare exceptions where fluids are highly specialized or processed under extreme conditions. For some applications, two different materials may be suitable with cost being the final deciding factor.

Other factors to consider in selecting the right diaphragm include the hardware configuration of the pump, type and frequency of cleaning fluids, pump operation (intermittent or continuous), and how often diaphragms are being replaced. On average, diaphragms that need to be replaced more often than every three months warrant further evaluation as to the right fit for the application.

Wilden® offers the widest selection of diaphragms for nearly every application. From aggressive chemicals to highly abrasive materials to extreme operating temperatures, Wilden has the right diaphragm for superior durability, higher performance and significant labor savings.

CONCLUSION

Whether pumping water, aggressive acids, food products or solid-laden slurries, there is a Wilden diaphragm for every application. The challenge can often be selection of the optimum diaphragm that will assure safe, efficient, cost effective and trouble-free operations. Determining the correct diaphragm requires carefully identifying and factoring all process and application parameters into the analysis. A valuable resource to assist with diaphragm selection is the network of Wilden distributors, who have extensive training in AODD pump technology and applications. Because one selection factor can offset another, expert advice should be obtained in determining compatibility based on all factors.

NOTES

Hytrel®, Viton® and Teflon® are registered trademarks of DuPont™ Company.

Geolast® and Santoprene® are registered trademarks of ExxonMobil.

Saniflex™ and Wil-Flex™ are registered trademarks of Wilden®.

About the Author

Glenn Dobbs is president of VAF Filtration Systems, Arvada, Colorado, and has developed the company into providing state-of-the-art self-cleaning screen filtration products worldwide removing suspended solids down to 10 micron. Roy McDougall is senior projects manager for Hydrochem of Australia and has provided cooling tower treatment services including filtration for more than thirty years. For more information, visit www.vafusa.com.

MODERN PUMPING TODAY, September 2014

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!