Keeping an open recirculation cooling water system clean accomplished three crucial operational goals and a fourth overriding goal for sustainability:

- Assists in maintaining heat transfer efficiency—0.025 millimeters of fouling equates to 10 percent reduction in cooling efficiencies (see reference 1),

- Reduces maintenance costs, and

- Enhances the effectiveness of the water treatment program, which

- All contribute to reduced costs and increased cooling tower system life.

Open systems are prone to fouling from airborne contaminants, water borne contaminants and contaminants associated with a process. Air contains dust, dirt, organic matter, insects, microbiological organisms and gasses. Make-up water can contain a variety of dissolved salts, suspended solids and microbiological organisms. Systems can also produce suspended solids from within due to corrosion, scale and microbiological growth.

Filtration is commonly employed to remove these contaminants from the water and improve the circulating water quality. Centrifugal sand separators (which are not considered filters), deep bed media filters, and automatic screen filters all offer varying effectiveness in the way each technology actually removes material from the circulating water. Each of these technologies also differs in their respective benefits and associated costs. Filtration, separation and other water cleaning systems can be either in-line or side stream, and basin cleaning systems can enhance contaminant removal. Understanding these technologies and their differences are necessary for proper technology selection.

CASE STUDY

The following case study describes one end-user’s experience with multiple filtration technologies and their inherent advantages and disadvantages in their cooling tower systems. In part 1, we’ll examine deep bed and sand media systems. In next month’s conclusion, we’ll take a closer look at centrifugal sand separators, piston operated self-cleaning screen filters, and finally—what is becoming the technology of choice for cooling tower filtration applications—automatic self-cleaning screen filters.

A patented self-cleaning screen filtration technology was supplied by VAF Filtration Systems from the USA and was installed and commissioned by Hydrochem of Australia in 2013 at a major entertainment complex in Australia. VAF’s V-Series filters were supplied to replace three other types of filtration technologies serving ten individual cooling tower systems. The older filtration technologies were not meeting the end-user’s strict Key Performance Indicators for cleanliness, and subsequently the cooling systems required an unacceptably high frequency of manual cleaning. So the end-user chose to install a newer filter technology to minimize problems associated with the older technologies. The replaced technologies included deep bed media, centrifugal separators and piston operated self-cleaning screen filters. The following describes each installation, the technologies installed and the end-user’s experiences with each.

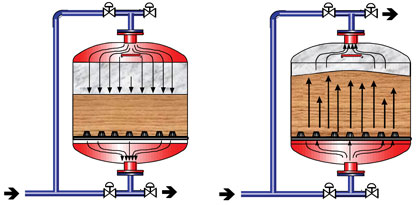

Figure 2: Typical sand media configuration

DEEP BED MEDIA FILTRATION

One hotel building in the complex has a cooling plant consisting of four common cooling towers with 7925 gallons (30,000 liters) total system volume. These were originally fitted with six deep bed media filter units that operated for approximately two years. In that time the deep bed media systems maintained the cooling towers in a clean state; however, they were found to require very large amounts of water for backflushing which caused the cooling tower system to lose the majority of chemical treatment every time the filters were backflushed. The media filters were then reconfigured to utilize two filters per week on a rotating basis to minimize the water losses.

However excessive water loss through backflushing was still found to be a problem. In addition to the water loss, a number of the media vessels’ control valves failed and allowed large volumes of media into the cooling system damaging the chiller system’s VSD’s (variable speed drives) and fouling the condensers. Also, the required periodic replacement of media was very expensive.

The media filters were replaced with two VAF V-250 filters which are operating well maintaining the cooling tower basins in a clean state while removing the residual media from the system.

Deep bed or sand media filters typically require a relatively large volume of water to backflush the media of contaminant trapped within. With a sand media system that requires 1,200 liters of waste to backflush, the equivalent size of VAF’s self-cleaning screen filter uses only 30 liters to backflush. Backflushing sand media takes full flow for at least three to five minutes, and the tank being flushed must be completely off line during the backflush process.

SAND MEDIA

Sand media can remove most particulate that are 10 micron and larger; however, it is difficult to backflush heavy particles (such as dirt, sand or calcium carbonate) collected from the tower without losing some of the media during each flush. Therefore, expensive periodic replacement of the media is required. Sand media is excellent for removing organic particulate including algae and sediment from the water and retaining those particles in the media. It has been shown by the EPA that sand media filtration on cooling towers and hot tubs provides an excellent habitat for bacteria such as Legionella since the organics combined with the sedimentation held within the media are the major source of nutrients for Legionella (see reference 2). ■

REFERENCES

- Systems and Equipment Handbook (2000), ASHRAE.

- “Legionella: Human Health Criteria Document” (1999), Office of Science and Technology / Office of Water, United States Environmental Protection Agency.

About the Author

Glenn Dobbs is president of VAF Filtration Systems, Arvada, Colorado, and has developed the company into providing state-of-the-art self-cleaning screen filtration products worldwide removing suspended solids down to 10 micron. Roy McDougall is senior projects manager for Hydrochem of Australia and has provided cooling tower treatment services including filtration for more than thirty years. For more information, visit www.vafusa.com.

MODERN PUMPING TODAY, September 2014

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!