By Chris French

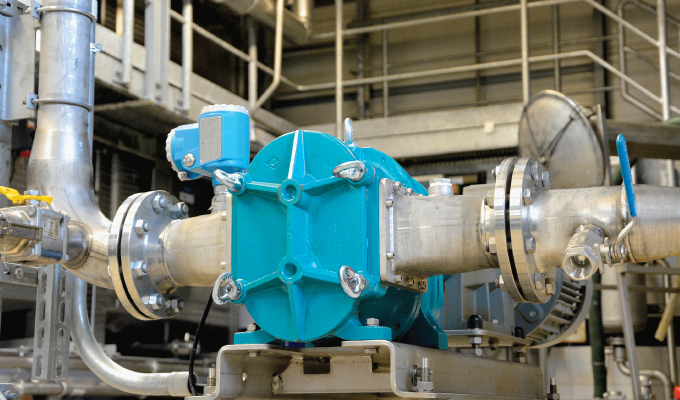

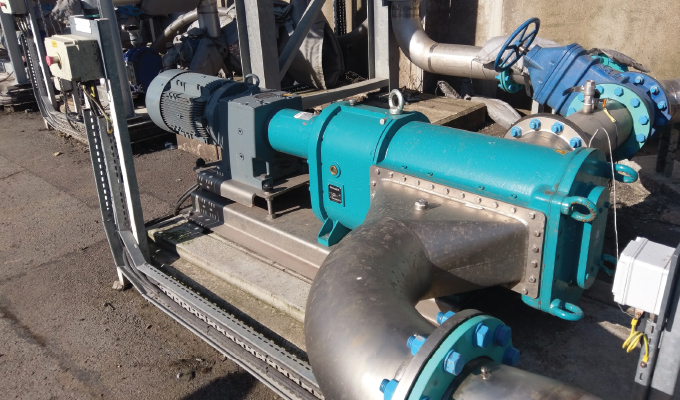

An innovative new Borger pump at Cliff Quay Wastewater Treatment Works is significantly improving the blend of liquified sludge and cake for Anglian Water’s anaerobic digestion (AD/biogas) process.

Working closely alongside Anglian Water and long-established engineers, Panks, Borger have also helped meet the challenge of mixing a rectangular tank that was proving far too difficult for existing equipment.

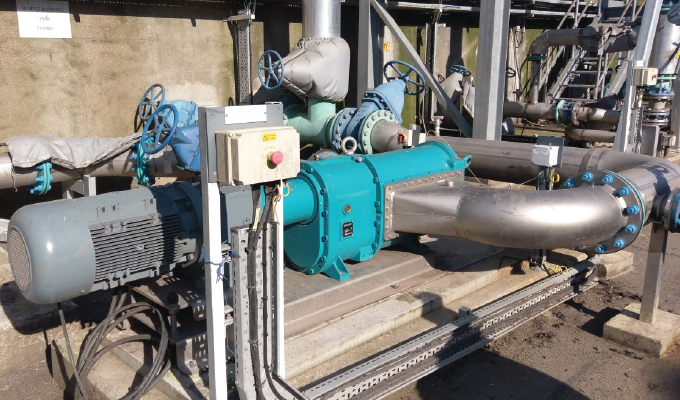

RECTANGULAR TANK MIXING HEADACHE

Jon Hooper, Cliff Quay treatment manager for Anglian Water, says, “As well as bringing about a better, more consistent product to feed the AD process, Borger and Panks have effectively helped us solve a problem without needing to install a new tank.”

He adds, “Mixing sludge in a rectangular tank is always a difficult task, but a paddle mixer at the deep end had difficulty coping with the solids, while the vortex pump at the shallow end of the tank kept air-locking.”

To put the Borger EL rotary lobe pump to the test—and ensure that a new set-up would work for Anglian Water—Panks first tried pumping through the existing pipework, but there was too much pressure at the jet end.”

BETTER BIOGAS FEED

Chris Bone, contracts manager at Panks, explains, “We then tried with some temporary pipework in a different configuration and this mixed the tank much, much better.

“Despite the considerable limitations of a rectangular tank, there was no doubting the capability of the Borger pump, so together with Anglian Water, we agreed to install additional stainless-steel pipework with three injection points at strategic locations.”

Now, with cake that comes in at 17 percent solids, with the surplus activated sludge (SAS) at approximately 3 percent to 4 percent, Anglian Water are able to achieve the optimum level of 8 percent solids—without the previous air-locking and burn-out issues.

Anglian Water’s Jon Hooper adds, “The mix of cake and liquified sludge is quite gritty, but since the installation by Panks of the new Borger pump, we’ve successfully improved the blend—which is quite an achievement with it running 24/7 and dealing with such high volumes—around 35 tons per day.”

HAPPY WITH FRUIT COCKTAIL DIET

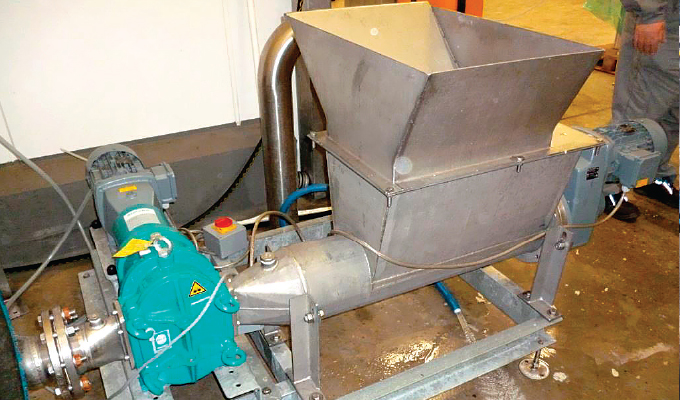

In another case, after problems with an unreliable screw pump, a fruit canning factory has invested in a new Rotary Lobe Pump from Börger. The old pump was unable to cope with large segments of apples, pears, and—in particular—peach stones.

Working at 6 bar (max), the new stainless steel Börger rotary lobe pump transfers the fruit bi-products, which are stored manually and then transported via a conveyor belt to the infeed hopper of the pump. The fruit and the resulting pulp is then transferred several hundred metres to a separate processing facility, where fruit juice is produced.

Following the success of the rotary lobe installation, the canning factory has since purchased two smaller Börger pumps with auger feed.

TRUE GLUE PERFORMANCE

Lastly, despite a very challenging application of handling a thick glue mixture in the production of corrugated cardboard, a Börger Rotary Lobe Pump is working trouble-free at a large packaging manufacturer.

Suitable for intermittent operation, the Börger pump (from the company’s proven Blueline range) benefits from a multi-seal K-shaft seal system, which has helped in it requiring only basic maintenance since its installation.

Börger’s Blueline rotary lobe pumps, available in twenty-one different pump sizes and a wide selection of materials and rotors, are designed as continuous runners.

Also available is the Börger ONIXline pump range, which features flow-optimized casing, robust carrier and timing gear that make it very effective for high pressure applications.

FOR MORE INFORMATION

Siemens Digital Industries Software, a business unit of Siemens Digital Industries, is a leading global provider of software solutions to drive the digital transformation of industry, creating new opportunities for manufacturers to realize innovation. With headquarters in Plano, Texas, and over 140,000 customers worldwide, we work with companies of all sizes to transform the way ideas come to life, the way products are realized, and the way products and assets in operation are used and understood. For more information, visit www.sw.siemens.com.

Börger designs, produces, and sells pumps, chopping units, and entry technology for pumping low to highly viscous and abrasive media—including its core component, the patented Rotary Lobe Pump. For more information, visit www.boerger.com.

MODERN PUMPING TODAY, October 2019

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!