The COVID-19 pandemic has had huge effects on economies around the world, including reducing raw material production, limiting workforce availability, suppressing demand for many products and services, and reducing the ability to travel. Businesses have adapted to these challenges in numerous ways, changing working procedures, stockpiling goods, and working remotely where possible.

In many cases working remotely is straightforward with good levels of online communication and access to the necessary technology. For many office-based workers it is as easy to complete their jobs from home (provided domestic distractions can be minimized) as from their desks. Restrictions on global travel have also increased the use of remote working by international businesses: while holding online meetings may be more convenient and better for the environment than flying halfway round the globe for a half-day conference, there are some things that, according to conventional wisdom, can only be carried out successfully in person.

TECHNOLOGY TO THE RESCUE

Until recently several stages of production and installation of manufacturing equipment would have fallen firmly into this category. Clients would have travelled to manufacturer’s facilities to carry our Factory Acceptance Testing (FAT) as new projects were begun, and manufacturer’s engineering staff would visit the client to assist with the final installation and commissioning of the finished equipment. Over the last two-years COVID-19 has made many of these trips impossible, or harder to justify.

Technology has once again come to the rescue, with remote metrics and connections to machinery and equipment allowing the equipment manufacturer’s own staff to assist local onsite engineers with the connection, installation, and commissioning of new equipment. Over the last two years HRS Heat Exchangers have used such an approach at both national and international levels to assist with the installation of a wide range of equipment

FAT helps verify that newly manufactured and packaged equipment meets its intended purpose, validating the operation of the equipment and making sure that customers’ purchase order specifications and other requirements have been met. Later in the supply process, commissioning can be defined as a systematic process of verifying that all equipment and facilities perform interactively in accordance with the design and intent, and in accordance with the client’s operational needs, including the preparation (and training) of operational personnel. It is usually carried out between the design phase and up to one year after installation.

INDUSTRY 4.0 AND VIRTUAL INSPECTION

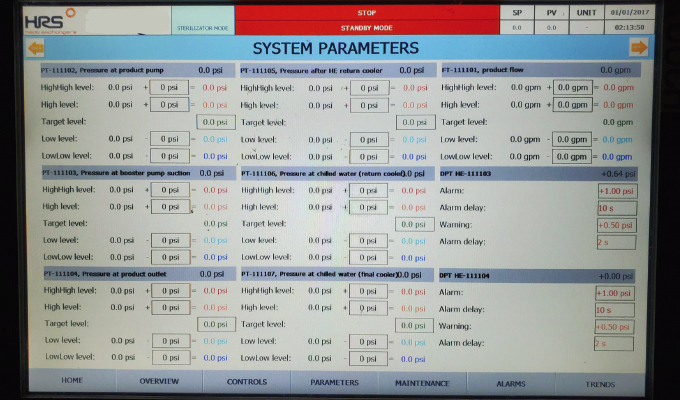

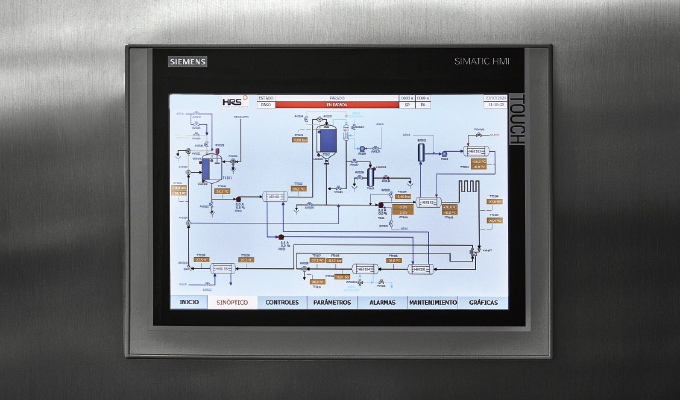

Thanks to remote telemetry, engineers and others can perform virtual inspection of assets and can see virtually what works and what doesn’t, including “fault” finding and identification. These digital solutions help to reduce the number of personnel on site as well as the duration of tests and can be applied to both FAT and final commissioning.

Remote commissioning is becoming one of the most visible aspects of Industry 4.0 and the Internet of Things (IoT). Although each case will be different, there are a number of stages which are common to most remote commissioning processes, including verification that the plant or equipment has been installed in accordance with the plans and piping/instrumentation diagrams. There is also likely to be a pre-commissioning stage that includes systematically checking connections, wiring and human-machine interfaces (HMIs) as well as installing and updating software components, cleaning, flushing equipment, etc.

The actual remote commissioning process will also consist of various steps but is greatly assisted by remote monitoring and telemetry of equipment using either an ethernet connection or an integrated data SIM. This allows system software to be adjusted as necessary while the equipment is operating. Other parameters and physical adjustments can be discussed during online meetings facilitated by conferencing systems and other forms of communication, such as WhatsApp. To date HRS has carried out a number of successful projects have demonstrated the effectiveness of this approach.

THE BENEFITS COMPOUND OVER TIME

One practical aspect which must be considered when operating internationally is the potential time difference between the on-site engineering team and the equipment supplier and overcoming this presents some logistical challenges and additional costs. However, none of these issues are insurmountable. When additional out-of-hours overtime charges are compared to the costs of travel and accommodation, there are often financial benefits, not to mention to considerable the reduction in carbon emissions and unproductive time spent traveling.

These benefits are undoubtedly one of the drivers which will ensure that remote commissioning continues to be carried out in the future whether or not our ability to travel is limited by the COVID-19 pandemic or other unforeseen factors.

ABOUT THE AUTHOR

Matt Hale is international sales and marketing director for HRS Heat Exchangers Located in Atlanta, Georgia, the company is part of the HRS Group, which operates at the forefront of thermal technology, offering innovative heat transfer solutions worldwide across a diverse range of industries. With forty years’ experience in the food and beverage sector, specializing in the design and manufacture of an extensive range of turnkey systems and components, incorporating its corrugated tubular and scraped surface heat exchanger technology, HRS units are compliant with global design and industry standards. For more information, visit www.hrs-heatexchangers.com.

MODERN PUMPING TODAY, April 2022

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!