Experienced industrial automation manufacturer and an industrial internet of things tools developer Opto 22 today announced a groundbreaking new industrial system to address the needs of automation engineers and developers. This system solves the challenging automation and industrial internet of things (IIoT) problems in today’s fast-moving, data-centric environment.

This completely new system brings the future of automation to the present by combining guaranteed-for-life I/O, real-time control, local and remote HMI, and industrial/IT data exchange in a compact, industrial package.

MANY FUNCTIONS, SIMPLE SOLUTIONS

Current IIoT solutions typically require multiple moving parts, including stitched-together software technologies, bolted-on communications protocols, legacy controllers and I/O, and a medley of gateways. These solutions are expensive to build, difficult to troubleshoot, require multi-domain expertise, and are unsustainable over the long term. The new groov EPIC® system helps solve these problems by combining I/O, control, data processing, and visualization into one secure, maintainable, edge-of-network industrial system. Opto 22’s groov EPIC lets engineers and developers focus on delivering value, not on triaging loosely connected components.

“We are a company of engineers inspired and driven to create products that unleash our customers’ imaginations,” says Mark Engman, Opto 22 CEO. “groov EPIC is a culmination of that mission, a response to industry requests to more wholly integrate IT and OT technologies, simplify development and deployment, and provide a platform for long-term growth now and well into the future.”

Combining reimagined intelligent I/O with an embedded Linux® real-time controller, gateway functions, and an integrated display, groov EPIC offers field-proven industrial hardware design with a modern software ensemble, to produce the results that visionary engineers want today. Connecting legacy systems, controlling processes and automating machines, subscribing to web services and creating mashups, acquiring and publishing data, visualizing that data wherever it is needed, and mobilizing operators—all of these are now within reach. In addition, groov EPIC simplifies commissioning and wiring and helps engineers develop rapidly and deploy quickly.

“The groov EPIC system incorporates in one unit everything needed to connect and control field and operational devices and data, through on-premises IT databases, spreadsheets, and other software, to cloud storage and services—and back again,” says Benson Hougland, Opto 22 vice president of marketing and product strategy. “This ability to easily exchange data and use it where needed opens opportunities automation engineers have not had until now. This is a truly new system that builds on the past but looks fundamentally to the future of our industry.”

MULTIPLE EFFICIENCIES IN ONE PACKAGE

The groov EPIC system will be of particular interest for process control, machine control, original equipment manufacturers (OEMs), manufacturing, SCADA/RTU, building and facilities, and IIoT applications. Commercial, retail, warehousing, and distribution customers will also find that the system opens a wide variety of new options for tracking, storing, and visualizing data—all of which are essential to developing more efficient operations.

Of particular interest to OEMs will be optional access to the Linux operating system through a secure shell (SSH). This access, along with toolchains and interpreters for Java, C/C++, Python, JavaScript/Node.js, and more, allows OEM developers to execute their own custom-developed applications on this ruggedized, edge processing control system.

REAL-TIME CONTROL, HMI AND DATA HANDLING FUNCTIONALITY

Additionally, the recent release of PAC Project Software Suite R10 supports the groov EPIC® system, adds eight new control commands, and provides the ability to designate individual I/O and variable tags as Public Access for read-only or read-write use in IIoT data communications via MQTT/Sparkplug. As in previous versions, HMI programming is included, and it uses the same tag name database as the real-time control engine, creating automatic integration between the two functions.

In the past, many process automation projects were solely focused on real-time control, but nowadays operator interface and data handling are often just as critical, sometimes more so. Therefore, it’s more important than ever for programming software to include not only a powerful real-time control engine but also closely integrated human-machine interface (HMI) and data handling functions, all in one integrated development environment.

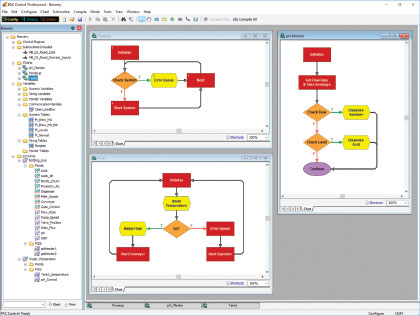

Opto 22’s industrial controllers—SNAP PAC programmable automation controllers and now groov EPIC edge programmable industrial controllers—are typically programmed using the PAC Project Software Suite. PAC Project Basic, free for download, includes flowchart-based control programming with optional scripting, a configuration utility, and HMI development. PAC Project Professional adds an OPC server, database connectivity, PC-based control configuration and support for legacy Opto 22 I/O units.

HMI programming is provided with PAC Display. PAC Display Basic is a user-friendly HMI package for building operator interface applications to communicate with groov EPIC processors, SNAP PAC controllers and Ethernet-based I/O units. PAC Display offers rich features including alarming, trending, security and a library of over 3,000 industrial automation graphics.

PAC Display Professional adds the capability to use redundant scanners and redundant Ethernet links on groov EPIC processors and SNAP PAC controllers. PAC Display Professional also enables logging of SuperTrends, historical logs and runtime operator logging data files to an ODBC database.

The suite’s control programming software, PAC Control, is full-featured and easy to use, with more than 450 commands in plain English, plus graphical PID tuning and debugging

Software features include:

• groov Manage software for tool-less configuration, commissioning, and debugging on-board and from anywhere on the network

• PAC Control flowchart-based control development environment with scripting and a visual debugger

• groov View visualization server for creating and viewing HMIs, trends, and events for any mobile device or web browser; also viewable

locally on an integral touchscreen

• Node-RED flow-based development environment and runtime for edge data processing, handling, and communications

• Ignition Edge® from Inductive Automation® with drivers to Allen-Bradley®, Siemens®, and

more

• MQTT/Sparkplug protocol for efficient, industrial publish/subscribe communications

• 100 percent backward compatible with SNAP PAC systems and SNAP Ethernet I/O

• Available secure shell access, SDKs, and cross-compiler for custom user-written applications

COMPATIBILITY IS KEY

The most important new feature with this new release is support for groov EPIC. Its control logic and I/O can be programmed with PAC Control, and customers can use PAC Display to develop a Microsoft Windows-based HMI to run on a separate PC. The groov EPIC’s integrated high-resolution touchscreen is not configured with PAC Display but is instead configured with groov View software, supplied free with groov EPIC.

New commands added to PAC Control include two specifically for groov EPIC: Get I/O Channel Quality and Get I/O Unit Quality. The groov EPIC I/O modules incorporate LEDs that change color based on the health of the module, revealing data quality to a local technician, and this information can also be configured or retrieved programmatically in control logic using these two new commands.

Another major new feature is full support for MQTT/Sparkplug data communication, provided by Ignition Edge, which is embedded in groov EPIC. MQTT’s publish-subscribe communication architecture is superior to request-response methods, and Sparkplug optimizes MQTT for industrial applications.

Public Access tags are a new PAC Control capability, making it easier and more secure to use MQTT/Sparkplug. During configuration, the developer can use Public Access to designate which tags to expose and to designate each exposed tag for read-only or for read-write.

Tags in PAC Control include I/O channels and program variables, some of which can be represented in the Public Access space in more than one way. For example, an integer can be represented as an integer, a Boolean value or an individual bit within the integer. A table can be represented as a table, one element in the table or even one bit of one element—providing a great deal of flexibility in how tags are exposed or protected.

CONCLUSION

PAC Project Software Suite R10 combines all of the most-needed industrial automation elements, aimed squarely at making it easier for end users to configure control, HMI, and communications functionality.

FOR MORE INFORMATION

Opto 22 designs and manufactures industrial control products and Internet of Things platforms that bridge the gap between information technology (IT) and operations technology (OT). Based on a core design philosophy of leveraging open, standards-based technology, Opto 22 products are deployed worldwide in industrial automation, process control, building automation, industrial refrigeration, remote monitoring, and data acquisition applications. Designed and manufactured in the USA, Opto 22 products have a worldwide reputation for ease-of-use, innovation, quality, and reliability. For more information, call 951.695.3000 or visit www.opto22.com.

_______________________________________________________

MODERN PUMPING TODAY, July 2018

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!

![]()