The new facilities include efficient cleaning and recycling of the abrasive media.

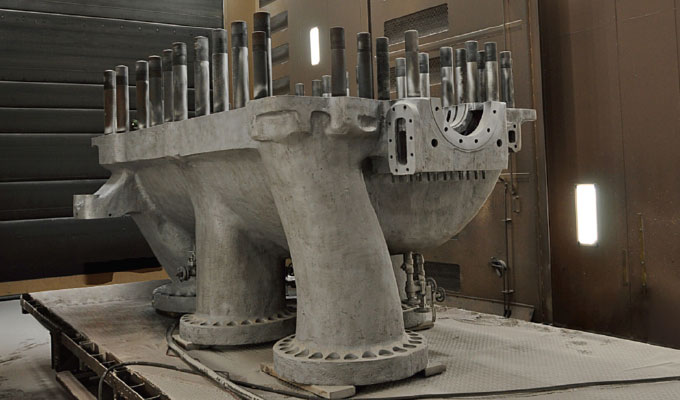

One of the first steps in many repair and overhaul projects is to remove any corrosion and old coatings to reveal the true condition of the base material. Customers can now take advantage of specialized blast equipment that has been acquired by Sulzer to improve the efficiency of repair projects, even for large pieces of equipment, such as turbine rotors.

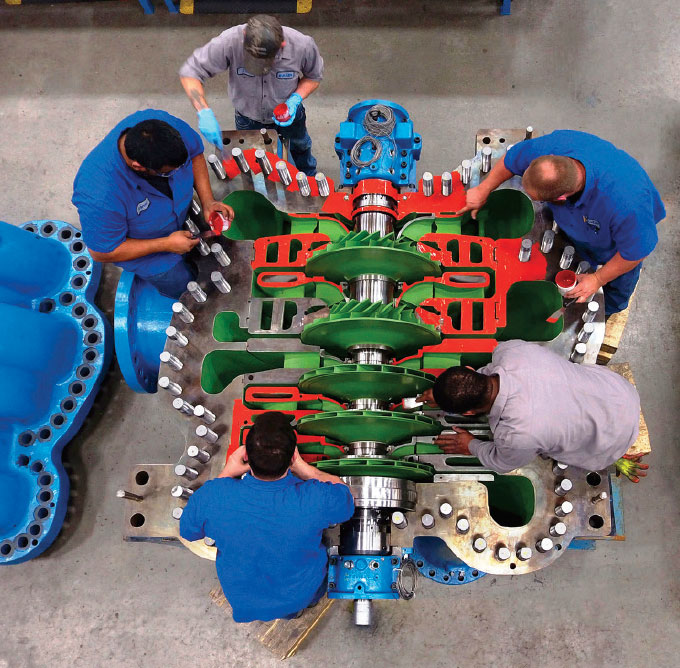

As a leading independent global maintenance specialist, Sulzer is renowned for delivering rapid repairs to a wide variety of rotating machinery including gas and steam turbines, compressors, generators, motors, and pumps. All this equipment is subjected to continuous corrosion and erosion during its time in service and when the time comes for an overhaul, it is essential that the initial cleaning process is achieved quickly and effectively.

Sulzer’s latest investment adds to the considerable facilities at its Houston Service Center. The new blast cleaning system is designed to be flexible in operation and effective at recycling the blast materials to minimize costs.

IN THE MAIN BLAST CHAMBER

Measuring 20 feet high, 16 feet wide, and 60 feet long, the main blast chamber can be sub-divided with a set of doors to allow two cleaning operations to be carried out at the same time but with different blast media. The scale of the new equipment means Sulzer has one of the largest blast facilities on the Gulf coast, and its flexibility means that it can also be used efficiently for smaller items.

The purpose-built blast room incorporates effective cleaning and recycling of the abrasive media as well as comprehensive dust collection apparatus to keep the local environment clean and contaminant free. The entry and exit to the blast room are designed to allow a large rotor to remain on its transport trailer, minimizing any risk of damage, and reducing the time required to complete the cleaning process.

This latest addition to our extensive list of equipment will enhance the speed and efficiency with which we deliver our customers’ maintenance projects. At the same time, the environmental safeguards will ensure our repair specialists have a safe working atmosphere.

As an integral part of the repair process, the new blast room offers a huge capacity that provides an excellent foundation for a refurbishment project. Its flexible design and ability to use, clean, and recycle a variety of blast media means the cleaning process can be completed professionally and quickly.

The new blast room has a huge capacity, allowing easy access for large components.

INVESTING IN THE FUTURE

Sulzer is dedicated to providing superior service solutions to a range of industries including power generation, oil and gas, hydrocarbon and chemical processing, water, and air separation. Every solution is customized to suit the business needs of each application—whenever or wherever that may be.

With a long history of providing engineering service support, Sulzer is headquartered in Winterthur, Switzerland where it began in 1834. Today, with sales over $3 billion and with approximately 14,000 employees, the Sulzer footprint spans across the globe. The core aim is to deliver a flexible and cost-effective service that optimizes customer operational efficiency and minimizes downtime.

Once cleaned, the equipment can be repaired, re-coated, assembled, and shipped back to the customer.

FOR MORE INFORMATION

Justin Ashford is division superintendent—core operations at the Sulzer Houston Service Center. Sulzer is the leading worldwide, independent service provider for the repair and maintenance of rotating machines including turbomachinery, pumps, and electro-mechanical equipment. With a global network of over 180 technically advanced manufacturing and test facilities, Sulzer offers a collaborative advantage that delivers high-quality, cost-effective, customized, and turnkey solutions, providing its customers with the peace of mind to focus on their core operations. For more information, visit www.sulzer.com.

_______________________________________________________

MODERN PUMPING TODAY, October 2018

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!

![]()