By Paul Brooks, Oerlikon Balzers

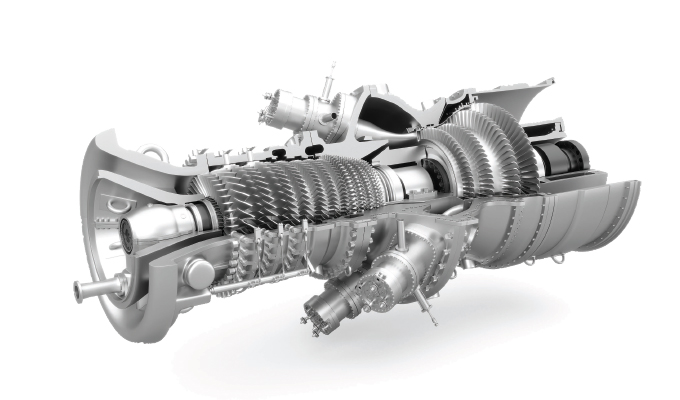

Industrial gas turbine (IGT) manufacturers and MROs are continually seeking new ways to improve the performance and longevity of critical components. To achieve this, high-value components must be designed and manufactured to withstand increasingly extreme temperatures, particle erosion, and hot gas corrosion stress.

Given the critical role of IGTs to utilities and bulk users of power, improving efficiency, and extending operating life of critical components is the key to managing costs while maximizing efficiency and uptime. Even seemingly minor factors such as the surface finish of compressor blades, for example, play a key role in increasing fuel efficiency.

As a result, OEMs and MROs are turning to advanced coatings that modify the surface of turbine components to improve wear and corrosion resistance, while also providing a lower coefficient of friction required for metal-on-metal contact of rotating parts such as shafts. One solution in this category that is garnering attention are physical vapor deposition (PVD) coatings for both IGT and steam turbine components.

There is a high demand from OEMs and MROs for proven and cost-effective solutions that can extend the life of key turbine components that are operating in hotter and more demanding environments in order to reduce MRO costs.

PROTECTING TURBINE COMPRESSOR SECTIONS FROM EROSION

Even today, the overriding goal of IGT OEMs continue to seek new ways to incrementally increase turbine efficiency. As a result, higher firing temperatures are often utilized, further increasing the temperatures inside turbines and leading to additional wear of component parts.

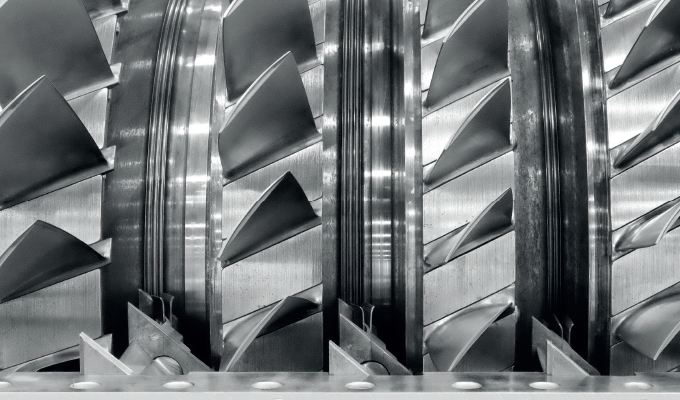

Erosion / corrosion and fouling of compressor blades, vanes, and inlet guide vanes (IGVs) is a concern, given that the surface finish has a direct impact on optimum airflow and, therefore, engine efficiency. This can occur as a result of many factors, including tiny particulate or moisture droplets that make it past air inlet filtration systems into the compressor section. An IGT located near a refinery, for example, can draw in polymers and sulfur from the air. Sand and salt are also common location-based issues.

Over time, the particulate sticks to the blades, creating a rougher surface that degrades turbine performance. As the blades foul, the efficiency of the entire compressor system eventually drops. This can drive up operating costs until the parts are serviced. Even then, parts that are re-polished to a mirror finish become quickly fouled again.

Ensuring that surfaces of compressor blades are maintained smooth during service will maximize air flow through the compressor and sustain compressor efficiency. This is an area where PVD coatings excel because of their unique combination of extreme surface hardness and a low friction coefficient. PVD coatings have only been used marginally in gas turbines to date, largely because of limited awareness in this sector.

Although the base material used to manufacture compressor section blades and vanes varies, and continues to evolve, most OEMs today utilize stainless steel, or apply a galvanic coating over a base steel. Unfortunately, galvanic coatings are relatively soft and erode over time. Due to the high cost of these components, solutions such as PVD coatings that are much harder and last longer are now considered a more ideal solution.

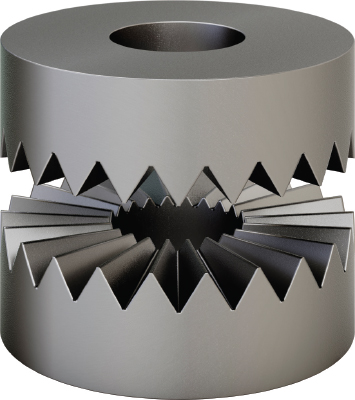

PVD represents a variety of vacuum deposition methods that can be used to produce very thin coatings, typically 1-5 µm in thickness. The thin coatings, in conjunction with close tolerancing, means that the component retains its form, fit, and dimensions after coating without the need for re-machining. Thicker coatings up to 25µm can also be applied, if needed, to increase erosion resistance.

PVD coatings also provide a viable alternative in replacing hard chrome plating. This comes at an opportune time, given the industry’s transition away from hard chromium plating to more environmentally friendly alternatives. For many years, hard chrome plating was the standard for achieving wear and corrosion protection, but due to European REACH regulations, the application of hard chrome plating is now highly regulated.

One REACH compliant PVD coating, Balinit® Turbine Pro from Oerlikon Balzers, is specifically geared towards protecting engine compressor blades, vanes and integrated bladed rotors (blisks) from particle erosion by maintaining a highly polished surface finish to retain efficiency gains for the lifetime of the part.

The formulation delivers a metal aluminum nitride (MeAIN) structure that results in an optimal relation of high hardness to residual compressive stress even under high thermal conditions. The PVD coating can be applied to steels, super alloys and titanium components and has an extremely low surface roughness once applied.

The high hardness of Balinit Turbine Pro has already been proven in solid particle, liquid droplet, liquid cavitation, waterjet, and other erosion tests with the coating on various substrates (steel, Inconel, and titanium) in different coating thickness and high temperatures.

In the solid particle erosion test in which materials were evaluated based on mass loss, for example, Balinit Turbine Pro demonstrated more than five times higher erosion protection than other PVD coatings, including titanium nitride (TiN). That value increased to more than 40X when compared to uncoated titanium and even more for steel.

THE HOT SECTION OF TURBINES

PVD coatings also show promise for the hot turbine sections of IGTs. Thermal protection is a key MRO consideration for components in the hottest section of a gas turbine where temperatures can exceed 800 degrees centigrade. The intense heat, which can be increased based on the magnitude of the load, as well as the type of fuel used for combustion, can significantly reduce the life of combustion components.

Oerlikon Balzers is currently working with leading IGT OEMs on development of a PVD coatings that address both erosion and the corrosion that occurs in the hot sections of the turbine. Given the variety of metal substrates utilized for component parts and the variable demands in different sections of IGTs, the company regularly collaborates with OEMs to advance new coating formulations.

As a global coatings provider to the IGT industry, Oerlikon Balzers has facilities in thirty-six countries across 111 locations. When there is a need to source or qualify a coating, it is an advantage to have a local supply chain and not have to send components to the other side of the world.

STEAM TURBINE COMPONENTS

Components of steam turbines also face high temperatures, erosion and fretting with the additional concern of steam-based corrosion. Steam turbines can operate on a standalone basis or in conjunction with gas turbines, as in the case of combined cycle power plants.

The primary concern when coating steam turbine blades and vanes is shortened life due to solid particle or water droplet erosion. As hot steam comes through to the high-pressure stage of the steam turbine, blades, and vanes are subject to solid particle erosion. As the steam cools and turns to liquid in the low-pressure stages, water droplet erosion becomes the subject issue.

A companion solution, Balinit D, was developed specifically for applications with high temperature steam to improve erosion and oxidation resistance.

Because of its extreme hardness and superior wear properties, the PVD coating allows OEMs to substitute expensive alloys with less expensive stainless-steel or chrome steel substrates.

EFFICIENCY GOES A LONG WAY

Coatings play an important role in extending the life of critical gas and steam turbines while maintaining optimal operating efficiencies. Consider that just a single percent gain in efficiency for a 200-megawatt gas turbine could represent the equivalent power needed for 1,500 homes.

Given the ever-increasing performance requirements of IGTs and steam turbines, there are more demands on the components. PVD coatings are an effective means to improve operational performance, reduce operational costs, extend operating hours, and reduce maintenance intervals.

FOR MORE INFORMATION

Siemens Digital Industries Software, a business unit of Siemens Digital Industries, is a leading global provider of software solutions to drive the digital transformation of industry, creating new opportunities for manufacturers to realize innovation. With headquarters in Plano, Texas, and over 140,000 customers worldwide, we work with companies of all sizes to transform the way ideas come to life, the way products are realized, and the way products and assets in operation are used and understood. For more information, visit www.sw.siemens.com.

Paul Brooks is lead segment manager of power generation at Oerlikon Balzers, a global OEM coatings provider to the industrial power generation industry. For more information, call 408.375.4408, email balzers.components@oerlikon.com, or visit www.oerlikon.com/balzers.

MODERN PUMPING TODAY, August 2019

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!