Process engineers responsible for keeping the pumps running in plants crowded with equipment and awkward pipe layouts will find the Vortab Elbow Flow Conditioner is an effective, low-cost solution to eliminate the turbulent fluid flows that result in pump cavitation, which can lead to line shutdowns, expensive maintenance, and shorter pump life.

ADDRESSING CAVITATION AT ITS START

Pump cavitation often occurs after liquid swirls and bubbles form in a pipe. These turbulent asymmetrical flow patterns create a vacuum suction that once it reaches a pump’s impeller will cause high-pressure shock waves. The resulting stress on the impeller blades pits them and requires extra maintenance or costly replacement.

All pumps require a smooth, regular symmetrical inlet liquid fluid flow profile for efficient operation. Pump manufacturers typically recommend 10 diameters of straight pipe be placed upstream from their pumps to avoid creating the turbulent flow conditions that can lead to pump cavitation.

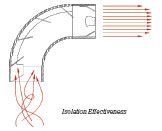

Many times, however, such a long straight pipe run is impractical because of insufficient plant real estate, the need for elbows or U-joints, flow meters, valves, and other equipment. In these all too real-world situations, the installation of a flow conditioner solves the problem by vigorous mixing action that eliminates the irregular flows prior to contact with the inlet port on the pump.

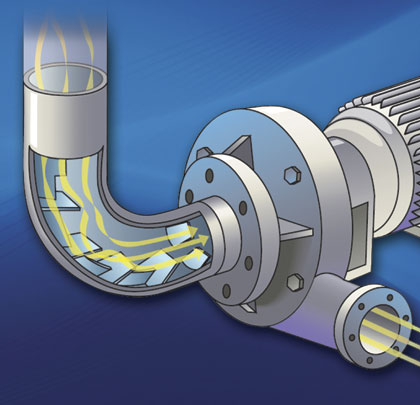

ELBOW FLOW CONDITIONER

The resulting pre-conditioned flow stream achieved with the Elbow Flow Conditioner mimics the straight run needed for efficient pump operation and removes asymmetric velocity flow profiles. In addition to conditioning the flow stream, the 90-degree angle tab-type Elbow eliminates the straight pipe run cost and installation technician labor.

The Vortab Elbow was developed using the same tab-type flow conditioning technology as the straight run Vortab Flow Conditioners, which have been laboratory proven and successfully installed in hundreds of plants worldwide. To validate the Elbow’s unique design-ball valves, gate valves, out-of-plane and in-plane elbows, and swirl generators were installed at the immediate inlet of the Vortab elbow and tested in the company’s state-of-the-art gas and liquid calibration facilities.

The Elbow Flow Conditioner isolates the flow irregularities and conditions the flow stream into a swirl-free and symmetrical velocity profile. Swirl reduction and velocity profile correction occur naturally in long lengths of straight pipe due to diffusion and turbulent mixing. Vortab’s anti-swirl and inclined vortex generating profile correction tabs, projecting from the inside pipe surface, generate vortices that accelerate these natural pipe effects to create a uniform, non-swirling, symmetrical flow profile in a much shorter section of pipe.

OVERCOMING THE PROBLEM OF CROWDED INSTALLATIONS

The simple, flexible designs of the Vortab Elbow, the Vortab Insertion Panel (VIP), and the Vortab Insert Sleeve, Short Run, Meter Run, and Field Kit configurations provide a cost-effective solution to crowded installations for flow meters and other critical process equipment. Vortab provides the most effective flow disturbance isolation, lowest pressure drop, and least affected by fouling of any of the flow conditioners available.

Vortab flow conditioners can be made from carbon steel, 316L stainless steel, or Hastelloy C-276. A variety of process connections are also available—ANSI flanges, male NPT threads, butt welded preps, or retaining wafers. Delivery time for the VORTAB flow conditioner is available in less than five weeks, depending on size. Custom configurations are also available from the factory.

For More Information

The Vortab Company is a global supplier committed to meeting the needs of its customers through innovative solutions to the most challenging requirements for optimizing flow meter accuracy and repeatability in gases or liquids. The Vortab Company manufactures flow conditioners and flow straighteners for flow meter, process, and pump system applications. For more information, visit www.vortab.com or call 800.854.9959.

____________________________________________

MODERN PUMPING TODAY, January 2016

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!