A number of primary advantages are linked to the use of peristaltic hose pumps for high density, abrasive paste transfer at precious metal mines. For competing pump types, there is a high degree of difficulty in handling abrasive paste with varying density, over long distances, and without frequent breakdowns. This difficulty is compounded when chemicals are added to the paste.

In summary, peristaltic hose pumps offer benefits that include:

- Significantly reduced pump downtime

- The ability to perform maintenance in-situ and without the need for special tools

- More efficient operations and higher productivity

- Greater safety through better handling of aggressive chemicals and abrasive paste

- Fewer filters required and filter capacity can be reduced by 75 percent. Disc filters cost around $100,000 each, so significant savings achieved

- No mechanical seal flush water is required: many centrifugal pumps need around 19 gallons of water per minute

- Less storage required for tailings; the number of basins or pools can be reduced, due to higher slurry density in less water

MINING FOR PRECIOUS METALS

A strong focus on water consumption is present within filtration-based mining as large volumes are required in the process. In the first stage, ore is crushed and ground, after which the fine ore is mixed with water in froth flotation cells, which serve to extract precious metals. The resulting tailings froth is thickened in a sedimentation tank, where the overflow is water and the underflow contains concentrated ore paste, typically 40 to 75 percent, reaching the higher end of this range at the bottom of the tank.

At precious metal mining facilities, it is desirable to have a thickener underflow with a high dry solid content; the less water involved, the higher the efficiency of the filter press. It is the pumps—which are installed beneath the thickener—that determine the maximum allowable dry solid content. As a result, pump technology is the limiting factor.

Mines often use at least two pumps per tank, one to lift from the tank and the other to feed a filter up to 980 feet away. Compared to heavy duty peristaltic pumps typical centrifugal slurry pumps cannot maintain accurate fixed flow rates against such pumping condition variations.

Facing Up to Social and Environmental Responsibilities

Precious metals are extracted at greater cost to the environment. Peristaltic hose pumps can help ensure the environment is better protected through safe and responsible transfer.

DRAWBACKS OF CENTRIFUGAL PUMPS

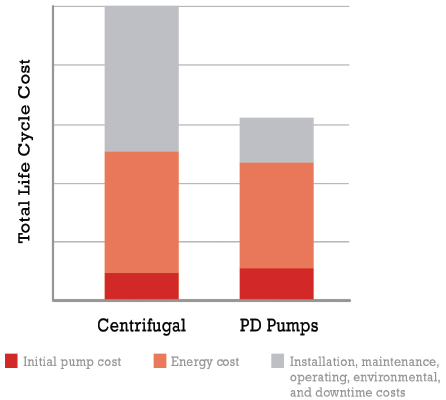

Centrifugal pumps are used widely in mining, especially for thickener underflow applications, but have many notable shortcomings. For example, the quantity of dry solids that can be accommodated by centrifugal pumps is limited. In numerous applications, impellers last just a few weeks due to factors such as strong acidity and/or abrasive content.

To overcome corrosion issues mine operators can use centrifugal pumps made of exotic high alloy materials to reduce frequent major component replacement. However, capital investment for these pumps is very expensive and abrasive wear rates no better.

Unlike other pumps, the performance of Bredel peristaltic hose pumps is not affected by the abrasive/aggressive nature of slurry and chemicals. Among the many benefits of peristaltic pumps are:

- No mechanical seals

- No requirement for seal gland water

- No seal water flush systems

- No moving parts in contact with the pumped fluid

- Pumping action without internal friction for increased wear resistance

The longer a pump can function without maintenance or downtime, the better. The wear-free performance of hose pumps is an attribute that results from a unique operating principle. Unlike other pumps, the abrasive nature of the product has no influence on pump life, so the need for routine maintenance and spare parts is greatly reduced.

Centrifugal pumps continue to run at the set speed, but flow rates decrease as the paste density increases towards the bottom of the underflow thickener (up to 75 percent solids are typically present in the bottom third of the tank). Bredel pumps keep pumping at the same flow rate, irrespective of the paste density.

Pumps like the Bredel hose pumps are virtually maintenance-free as there are no impellers, liners, casings, wear liners and seals to replace, no check valves to clog or wear out. The only wear part is the hose, which can be replaced in a matter of minutes without any requirement for special tools. Longer hose life enables customers to reduce maintenance downtime and spares inventory; two important aspects in rugged and remote mining duties.

Another benefit, certainly in terms of cost is that Bredel hose pumps can reduce filter capacity by as much as 75 percent.

Not only are disc filters very expensive, at circa $100,000 each, but the feed has to be constant to ensure working efficiency is maximized. However, even more relevant to dry solids content is the storage of tailings in the ponds. Also, less volume of paste means smaller dams are possible and reduced water content brings greater safety by reducing the risks of saturated dams. Reduced water content brings greater safety by reducing the risks of saturated dams.

A LOOK AHEAD

Moving ores, concentrates, and residues in slurry form are essential parts of industrial mining processes. However, mining operators must constantly seek ways to meet their social and environmental responsibilities. In next month’s conclusion, we’ll see how Bredel hose pumps were installed in several mining operations and faced up to the heat and wear of harsh conditions, proving the variety of peristaltic hose pumps in the field. In one case study, Bredel hose pumps demonstrate they can extract minerals in mines where centrifugal pumps could not manage such a high concentration of solids. In another, Bredel hose pumps prove their longevity despite the use of aggressive chemicals, including cyanide, where leaching dissolves gold out of the ore using a chemical solvent.

FOR MORE INFORMATION

Siemens Digital Industries Software, a business unit of Siemens Digital Industries, is a leading global provider of software solutions to drive the digital transformation of industry, creating new opportunities for manufacturers to realize innovation. With headquarters in Plano, Texas, and over 140,000 customers worldwide, we work with companies of all sizes to transform the way ideas come to life, the way products are realized, and the way products and assets in operation are used and understood. For more information, visit www.sw.siemens.com.

Watson-Marlow Fluid Technology Group (WMFTG) is the world leader in niche peristaltic and sinusoidal pumps and associated fluid path technologies. Founded on nearly sixty years of supplying engineering and process expertise and with over one million pumps installed worldwide, our pumps are tried, tested, and proven to deliver. For more information, visit www.wmftg.com.

MODERN PUMPING TODAY, June 2019

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!