Industrial Flow Solutions™ (IFS) OverWatch® direct in-line pump system offers a revolutionary solution for the municipal wastewater and stormwater industry. The OverWatch patented system is designed to eliminate the wet well by lifting influent directly from the inlet to the discharge while detecting and responding to solids, eliminating potential clogs. Operation is based on continuous pumping, decreasing backups by lifting influent directly at the entry point, without water loading. Because the system handles influent as it arrives, rags, fats, oils, and greases (FOG) have no chance to solidify and collect near the pump’s inlet.

APPLICATIONS

- Sewage and solids handling

- Stormwater management

- Wastewater

- Lift / pump stations

ELIMINATE THE WET WELL AND IMPROVE SAFETY

The OverWatch system creates safer working conditions for maintenance crews and reduces environmental impact. Because influent is contained within the system, it never becomes atmospheric. As a result, there is no buildup or exposure to hazardous odors, bacteria, or hydrogen sulfide (H2S) gases; work safety is optimized.

NO DOWNTIME FROM A CLOGGED PUMP

Redundant dual pump design maximizes reliability to reduce maintenance and extend the life expectancy of the system. Simplified installation and maintenance means no more screen cleaning and cost savings!

SELF MONITORING SAVES TIME AND MONEY

The OverWatch smart sensing system is designed to improved operational efficiencies as it adjusts in real time to manage flow, detecting and removing clogs without human intervention.

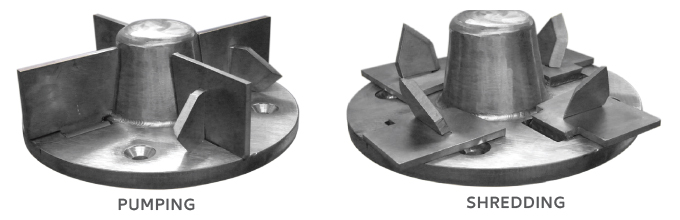

PATENTED DIPCUT® IMPELLER

Variable vane, vortex impeller design features hinged vanes that fold flat exposing shredding blades when operated in reverse rotation. When an elevated torque level above the threshold value is detected, the smart, self-monitoring variable frequency drive reverses the direction of the impeller rotation, changing its function to shred and remove the clog without human intervention, all without losing its high hydraulic pumping efficiency.

CASE STUDY: SHERMAN, NEW YORK

This rural community is home to 730 residents and a lift station that caused twenty-six hours of maintenance each year to remedy frequent pump clogging and weekly bar screen cleaning. The 36-inch silo access descending 20 feet into the ground compromised worker safety.

Solution: One OverWatch® System replaced two submersible pumps previously used to lift influent to the plant headworks, converting the pit into a dry well. Total annual cost reduction is nearly $8,500 in vacuum truck rental, removing clogs, manual bar screen cleaning/raking, and preventative maintenance, reducing total overall maintenance to twenty minutes over four years.

For more information, visit www.flowsolutions.com.