By Daniela Haldenwang, Sulzer

Asset reliability and performance are the two most important factors for the oil and gas sector but as processes change and equipment ages, optimizing uptime can become a greater challenge. For pumping assets, a retrofit project has the potential to increase productivity and reliability, while at the same time reducing energy costs.

Changes to pump performance may be required for a number of reasons. For instance, refineries looking to increase production will examine the assets involved and identify any bottlenecks. In some cases, flowrates will need to be increased beyond the existing capabilities of the equipment; a drilling well may need to increase water injection rates, or the reliability of certain assets may need to be improved to meet the new targets.

NEW FOR OLD

The first, and most straightforward, solution is to replace the existing pumps with new equipment that has been specified for the new production rates. This has many advantages in terms of reliability, performance and efficiency; using the latest materials and design technology will ensure a long-lasting and effective solution.

There are, however, some drawbacks—the time to complete the project, the lost production while the work is completed, and the overall capital expenditure. Together, these will nearly always rule this option out.

ADAPT AND SURVIVE

A more favorable option is to modify the existing assets to enable them to deliver the new targets. There are many challenges that can be resolved to some degree by implementing a retrofit project. Reliability issues can be improved through a change in materials to resolve erosion or corrosion; performance can be enhanced by altering the hydraulic design of the pump.

Retrofit projects are a very cost-effective alternative to replacing large assets when a production site requires a change in performance or an improvement in reliability. By minimizing the number of components being modified, both the time and the cost involved in the project are kept to a minimum.

For example, in Norway, the government offers support to the oil and gas industry to reduce its carbon footprint. One of the biggest gains can be achieved by reducing the energy consumption of pumping assets. Using a retrofit project to optimize pump performance to each application, operators have made significant savings in running costs, which help to meet national carbon targets.

OPTIMIZED PERFORMANCE

One of the major areas of pump operation is water injection systems, which are used to maximize the productivity of the oil wells. As the oil field matures, there is a need to increase the water injection rates to maximize oil production. This requires the capacity of the injection pumps to be increased without affecting the layout of the plant or the existing pipework.

In this case, the flowrate needs to increase while maintaining the head, which means that the power demand will rise and the pump design will need to be altered. By working closely with the platform engineers and establishing the limits of the motor or turbine, pump designers can draw up a modified hydraulic proposal that will improve both performance and efficiency.

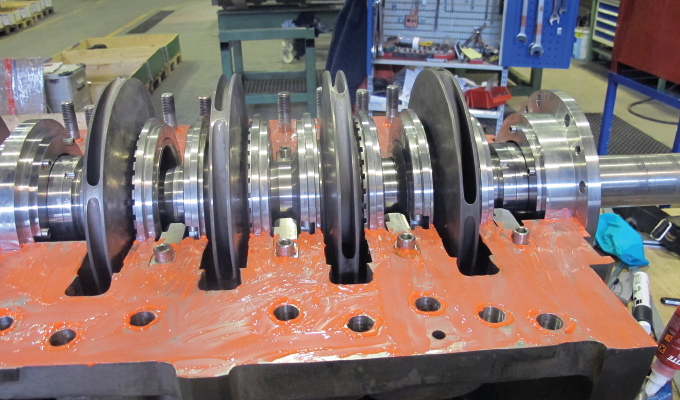

In an alternative scenario, the system pressure may need to be reduced, while maintaining the original flowrate. Reducing the pressure generated by a pump can be achieved by removing a number of stages from the pump rotor, which will significantly decrease the energy requirement of the pump. In some cases, the rerate solution may include a variable speed drive, which can deliver more flexibility in the output from the pump.

Rerating a pump’s hydraulic conditions to the new duty point, a combination of flow and head, will enable the system to operate more efficiently. Based on the downstream requirements, the pump characteristics can be redesigned so that it delivers the necessary flow and pressure while operating at or close to its best efficiency point (BEP).

CASE IN POINT

One of the largest offshore oil fields in the Middle East uses five BB5 injection pumps, four 9 MW pumps, and a 14 MW Sulzer HPcp pump, all of which are powered by gas turbines. The proposal was to increase production from the oil field, which would require the gas turbines to be upgraded to provide their maximum achievable power output. Having achieved this, all five pumps would be rerated to deliver the maximum possible injection flow rates using the increased power capacity.

As both a pump original equipment manufacturer (OEM) and an independent maintenance provider, Sulzer was awarded the contract to upgrade all five pumps. The objective was to achieve the best possible flow rates using as many existing components as possible, and with minimal disruption to the production schedule.

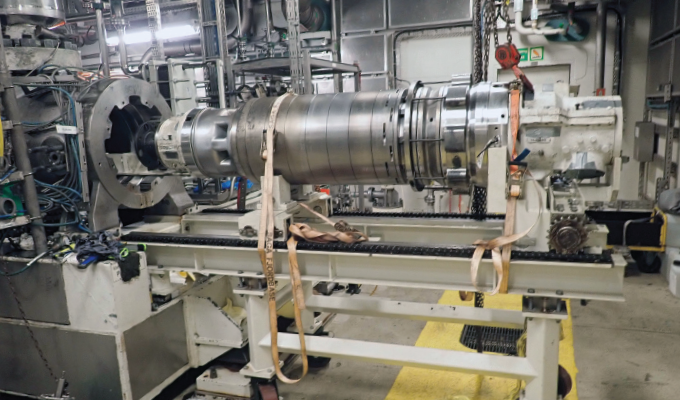

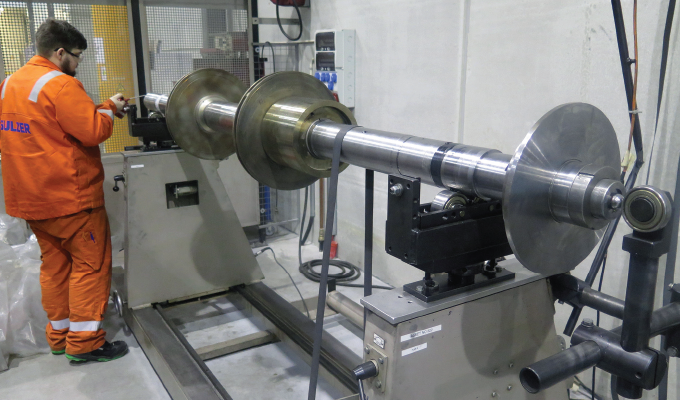

Sulzer had access to a complete, spare cartridge for the 9 MW pumps, from which all the necessary design information could be gathered and used as a base to modify the cartridge design. The proposal was to change the original four-stage design for a three-stage alternative with a similar diameter impeller. This allowed the existing pipework, lube systems, mechanical seals, bearing housings, and site interfaces to be retained.

INCREASING PRODUCTIVITY

Using the spare cartridge, Sulzer implemented the new barrel design and delivered it back to the platform where it took the place of one of the operational pumps. The whole process to remove and install the new barrel only took two to three days to complete, including commissioning. The original cartridge that had been removed was taken back to Sulzer’s engineering center where it underwent the same design rerate process.

Following this implementation plan ensured that operations on the platform were unaffected by the rerate project, eliminating any lost production costs and minimizing the amount of work that needed to be completed on the platform. The upgraded cartridges delivered a 25 percent increase in flow over the original design of the four pumps, with the total injection capacity rising by 30 percent.

This project was also extremely cost-effective. When compared to a project to procure new pumping equipment to do the same task, the rerate program saved the platform operator a total of $150 million, as well as avoiding all of the disruption that a new installation would create.

ONGOING SUPPORT

Oil and gas production facilities are driven by performance and equipment reliability, which can be enhanced by engineering expertise and design experience. By working with an engineering partner such as Sulzer that has a worldwide network of service centers as well as decades of experience in pump design, specifically in the offshore and oil and gas sectors, platform operators can optimize their business.

Rerate projects offer an opportunity to increase uptime, reliability, and therefore productivity. In some applications it is possible to improve efficiency, which reduces energy costs as well as the carbon footprint of the business. Whatever the goal, when it comes to pump performance, the retrofit project should always be considered as one of the prime options.

FOR MORE INFORMATION

Sulzer is a global leader in fluid engineering. We specialize in pumping, agitation, mixing, separation and application technologies for fluids of all types. Our customers benefit from our commitment to innovation, performance, and quality and from our responsive network of 180 world-class production facilities and service centers across the globe. For more information, visit www.sulzer.com.

MODERN PUMPING TODAY, August 2020

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!