Whether it’s at product launches, factory tours, or trade shows, the staff at MPT is afforded an up-close look at the newest offerings for our industry, and each December, we look back on the year that was and present our choices for the Top Products spanning the industrial pump and rotary equipment markets.

In the pages that follow, MPT shares its selections for the products that speak to the industry’s needs for efficiency, reliability, and innovation. Each of our Top Products was chosen through submissions from our staff, advertisers, and readers like you. The products range from large multinationals you’re likely familiar with to smaller, regional suppliers worthy of your attention.

Regardless of their size or reputation, they all offer value you can take into the new year. Enjoy!

To download a pdf version of the 2020 Top Products from our magazine, click here.

LIBERTY PUMPS

Model 404 and 405

As regions in the United States and Canada begin to re-open for business, they are doing so with some new requirements and restrictions on how they operate. To provide better sanitization, many are being required to add additional wash station areas for their employees and customers. The Liberty 404 and commercial model 405 are the perfect solution for these additions and remodels!

The opportunities exist in manufacturing facilities, restaurants, schools, health care facilities, and almost all public and commercial buildings!

Liberty’s model 405 is one of the few models made here in the U.S. that features high-temperature capability along with higher-head pumping (max head 34 feet). The 2-inch inlet, discharge, and vent allow it to be installed commercially on multi-compartment sinks, and it arrives fully assembled saving valuable labor time. Keep in mind we offer new versions with pre-installed alarms and NightEye® (Wi-Fi) enabled options for both the 404 and 405!

Our QuickTree® Technology provides a separate access cover for easy switch inspection. For gray wastewater applications, the 405 is perfect for laundry trays, multi-compartment sinks, bar sinks, utility sinks, dishwashers, and allows you the freedom to install fixtures where gravity drain lines are not available. The system arrives fully assembled and ready to install.

For more information, visit www.libertypumps.com.

MOD-TRONIC

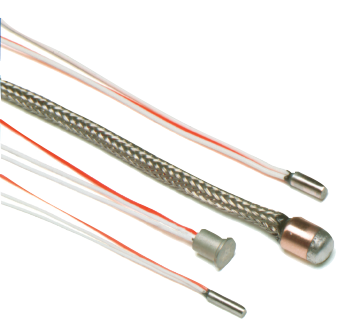

Minco Miniature Embedment Temperature Sensors

Minco Miniature RTD and Thermocouple temperature sensors can be configured for best fit to your application. Install miniature sensors in or beneath the babbitt layer of bearing shoes. They monitor metal temperature—the most reliable indicator of bearing condition—to give early warning of oil film breakdown. With predictive maintenance, machines can be shut down and the problem corrected before catastrophic failure occurs.

While no larger than many bare ceramic elements, these RTDs have metal cases and insulated leads to withstand rough handling and harsh environments. They are easy to install in drilled holes for general purpose sensing.

Tri-certified for use in hazardous areas to IECEx, ATEX, and North American (CSA, USA, and CSA Canada) requirements, these wide-ranging certifications allow users to cover many potential certification requirements with one sensor product, thus increasing flexibility and reducing inventory.

For more information, visit www.mod-tronic.com.

HELWIG CARBON PRODUCTS, INC.

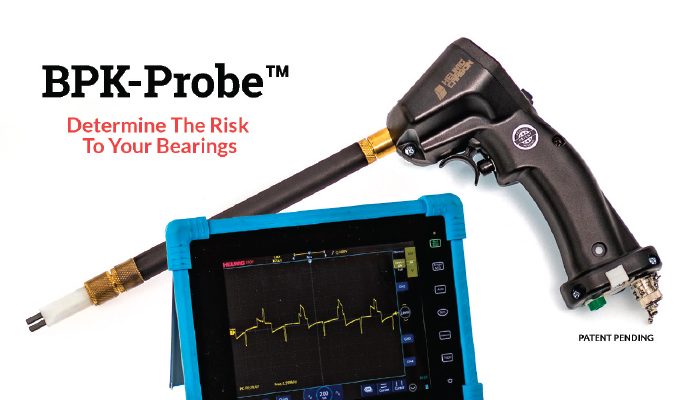

BPK-Probe™ Shaft Voltage Detection Device

Helwig Carbon Products, Inc. has developed the BPK-Probe Shaft Voltage Detection Device. The new device will provide a tool for –pump technicians to test a pump motor for the potential for bearing failures from induced shaft currents.

When a VFD controls a pump motor, there is a strong possibility that induced shaft currents are present. These induced shaft currents will seek a path of least resistance to ground, and that typically will be through the motor bearings. These damaging shaft currents will cause fluting and frosting of the bearing raceway and cause premature failure and a costly replacement.

The Bearing Protection Kits from Helwig Carbon Products are easily installed by pump motor OEM’s, pump technicians, and end-users. They can be installed in the field on most pump motors with an accessible shaft or coupling. Many end-users are willing to apply this kind of maintenance practice to their pump motors to protect their investment and reduce downtime.

For more information, visit www.helwigcarbon.com/shaft-voltage-detection-device.

BLACOH SURGE CONTROL

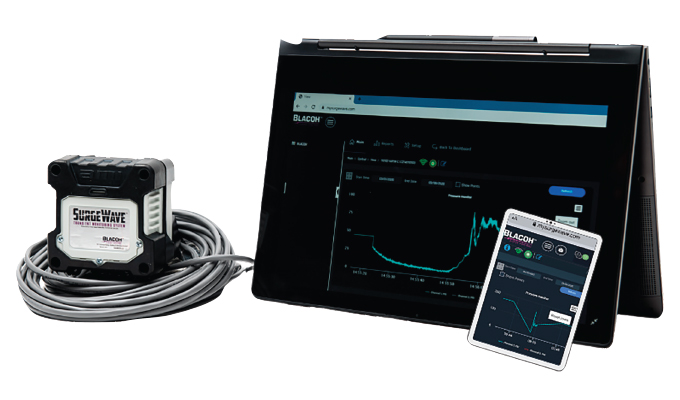

SurgeWave™ Defender™

Finally, transient pressure monitoring that makes sense. The patented Blacoh™ SurgeWave™ Defender™ is the latest generation pressure monitoring device from Blacoh Surge Control. This patented device can monitor and record transient pressures up to 100 times per second which is not possible with gauges and traditional SCADA systems. High frequency recording is the best way to capture high speed events occurring within your piping system. The SurgeWave Defender™ monitors your pumping and pipelines 24/7 with fast 4G LTG cellular connectivity. This allows you to fine tune your piping system and access critical data at any time. You can also configure your device and calibrate remotely from anywhere using your PC or smartphone.

The SurgeWave Defender™ is simple to set up and easy to use. There are two inputs to capture pressure, flow, level, etc. If a pressure transient occurs, the unit will store the high-speed data that you need to understand what is happening in your system. If nothing of interest is detected, it stores minimal data needed to observe overall trends. Transient thresholds and sensitivity can be adjusted remotely, and the system will generate automatic alerts when events are detected.

Liquid level in your surge vessel or pulsation dampener can be monitored using a differential pressure transducer. You can remotely monitor the performance of the vessel and view overall trends. All data captured is GPS time stamped and stored on a cloud server which can hold years of data, so you never have to worry about storage. The time stamp allows you to precisely compare data to other systems or devices. You can use a backup battery to capture pump trips and events during power outages. The SurgeWave Defender™ also features an external cellular antenna which can be extended for installations below grade.

When considering protection and recording equipment for your system, keep in mind how fast pressure can change and fluctuate. Pipe breaks are most often associated with pressure surges or fatigue. Eliminate expensive damage and repairs with 24/7 constant monitoring. The SurgeWave Defender™ can help detect leaks, ruptures, faulty actuators, insufficient air valves, and more. You do not have to choose between too much data and not enough data, and the easy to use interface takes the stress out of accessing your data anytime from anywhere.

For more information, visit www.blacohsurge.com.

AUTOMATIONDIRECT

High Bus Voltage (AC Input) Stepper Drives and Motors

AutomationDirect has added a high voltage AC drive and compatible high torque motors to its stepping system motion control product offering. The AC stepper drive is powered from 90 to 240VAC and is intended for use with step motors designed to handle a high bus voltage of 340VDC. MTRAC motors are specially designed to work with high bus voltages, providing much higher torque, especially at higher speeds. Stepper drive auto-setup measures motor parameters and configures motor current control and anti-resonance gain settings. The high voltage drive uses AC input 90 to 240VAC and output current is selectable from 0.6-2.5A/phase (peak of sine). Microstep resolution is switch selectable with sixteen settings from 200 to 25,600 steps/rev.

For more information, visit www.automationdirect.com/ac-stepper-motors.

BASETEK

Polymer Concrete Baseplates

Aeeping your rotating equipment level is essential. BaseTek polymer concrete baseplates offer precision flatness while providing significant vibration damping and superior corrosion resistance. Installation time and cost is greatly reduced by eliminating or reducing typical grouting activities in comparison with typical steel designs. Upkeep and preventative maintenance no longer required. Off-the-shelf availably for most ANSI/ASME pump products along with a complete range of custom configurations including the patented GreenShield Foundation Systems.

For more information, visit www.basetek.com.

WILDEN PUMP AND ENGINEERING COMPANY

SafeGuard Pump-Monitoring System

The Wilden SafeGuard all-inclusive pump-monitoring system remotely tracks, records, and alerts customers to key performance indicators—such as leak detection, stroke rate, and total stroke count—of AODD pumps during operation. It provides real-time alerts via SMS or email to indicate any noteworthy change in operations that may be a precursor to or indicators of component failure. Wilden SafeGuard also provides the ability to store maintenance records to help identify patterns to further enhance preventative maintenance plans. The Wilden SafeGuard solution has been designed to monitor a single pump or a fleet of AODD pumps within one dedicated software system.

For more information, visit www.wildenpump.com.

MEGALERT

MotorGuard

MegAlert manufactures the MotorGuard patented testing and protection systems designed to detect insulation breakdown in critical motors. The system senses when the pump motor is offline and then performs a continuous dielectric test on the winding insulation until the equipment is started again. When an abnormal condition is detected the equipment can be locked out and a warning signal sent, indicating that the pump motor needs maintenance.

Reduce risk to save lives! The testing is done with a current limited non-destructive DC voltage from 500 to 5,000 VDC, which is safe for both personnel and the equipment. By automatically testing offline equipment customers can now predict and prevent impending failures, reduce unscheduled downtime repairs, and increase plant safety by not exposing maintenance personnel to dangerous Arc Flash conditions experienced when performing manual testing.

MotorGuard applies a current limited, fixed DC voltage to the motor windings during idle periods. A solid-state comparator circuit monitors measured leakage current to the ground. Two adjustable set points, factory preset to customer specifications, can be programmed to signal a pre-alarm, alarm, and lockout the equipment from operating if the low set point is exceeded. The manual reset feature enables a return to operational status only after the alarm condition has been corrected. MotorGuard will not impair normal operation of the equipment being monitored.

For over three decades, MegAlert has offered this patented, cost-effective, and proven technology with almost unlimited applications to multiple industries in both the private and government sectors.

For more information, visit www.megalert.com.

YASKAWA AMERICA, INC.

GA500 Industrial Microdrive

In 2020, the Drives & Motion division of Yaskawa America, Inc. introduced the GA500 Industrial Microdrive, reflecting Yaskawa’s continued customer commitment to providing sustainable, flexible, and easy-to-use products. The easy-to-use GA500 is designed to maximize one of the most valuable user resources, time. The GA500 can be programmed without main power applied, which means users can set up the drive so it is ready to run before main power is available.

A highly visual LED status ring provides drive status at a glance. Yaskawa’s mobile app, DriveWizard Mobile, provides the ability to program and/or monitor the GA500 through mobile devices like a smartphone or tablet. DriveWizard Mobile instantly accesses the Yaskawa Drive Cloud, providing a safe location to store drive information with instant access anywhere.

For more information, visit www.yaskawa.com/GA500.

HMD KONTRO

CSA/CSI Pumps

HMD Kontro’s CSA/CSI line of magnetic drive sealless chemical service pumps features interchangeable parts that enable a few models to cover a wide range of chemical applications. For the safe and efficient transfer of toxic, corrosive, carcinogenic, and aggressive liquids, CSA/CSI pumps are designed of stainless steel with silicon carbide internal bearings, which enables them to withstand extremely high temperatures.

Most pump failures start with seal leaks. Upfront CAPEX for seal support systems is considerable, and OPEX for seal maintenance is unavoidable. But CSA/CSI pumps eliminate seals and associated support systems, providing an economical, reliable, and leak-free solution for handling toxic or hazardous liquids.

CSA/CSI pumps are easy to maintain, have fewer parts, no potential leak paths, and numerous other features designed to enhance reliability, safety, and environmental friendliness.

For more information, visit www.hmdkontro.com/csa.

JWC ENVIRONMENTAL

Monster Metal® Grinders

JWC Environmental relaunches its Monster Metal® grinders featuring a trade secret alloy and industry-leading five-year warranty.

Wastewater is tough on grinder cutters. Damaging abrasion wear and metal corrosion are caused by daily gritty material and acidic conditions in sewage. The combination of an abrasive and corrosive environment accelerates the loss of cutter material, resulting in the loss of cutter thickness and tooth edges.

Traditionally, there is a trade-off between choosing a material for abrasive environments and corrosive environments. Hard alloy steel has been the traditional choice of material for abrasive environments. Unfortunately, alloy steel is not a corrosion-resistant metal. The corrosion-resistant metal choice has been stainless steel but unfortunately, it has low abrasion resistance. Cutter material is typically selected based on the environment to which it will be exposed to optimize its performance and maximize cutter life. Regrettably, choosing a material suitable for one environment but not the other often leads to dissatisfaction with the cutter life.

Monster Metal is JWC’s solution to this problem. Monster Metal grinders feature cutters that last twice as long as typical industry cutters and work in both abrasive and corrosive environments commonly found in wastewater treatment plants. JWC conducted intensive in-house and field testing to validate that the proprietary material and design outperformed other cutters in wear resistance and corrosion.

“We’re excited to bring back Monster Metal to the wastewater treatment market. Previously, operators had to choose between corrosion resistance or abrasion resistance. With Monster Metal, they no longer have to compromise,” says Greg Queen, president of JWC Environmental. “And they can rely on a five-year warranty to increase the longevity of their grinder cutters.”

Monster Metal is available on select Muffin Monster®, Channel Monster®, and Channel Monster® FLEX units. A five-year warranty covering the cartridge and wear components is included on Muffin Monster units while a three-year warranty is available for Channel Monster and Channel Monster FLEX units.

For more information, visit www.jwce.com/knowledge-center/monster-metal.