You are reading this publication because you want your process pumps to be reliable. That’s a commendable aim, but it pays to be judicious when we select steps to get to higher reliability. Making informed choices is of great importance and not all roads lead to the desired goal.

As an example, some tradition-bound reliability engineers simply look at old specifications and make them tighter. They often do so in a misguided and ill-defined effort to improve equipment reliability. The fallacy of simply tightening a specification is best shown in four recent case histories. Each deals with fluid machinery and illustrates that tighter specifications do not automatically translate into smarter, life-extending specifications. Smart specifications are those that increase safety, equipment reliability, and bottom-line profits.

HIGH TEMPERATURE PROCESS PUMPS AND LUBRICATION

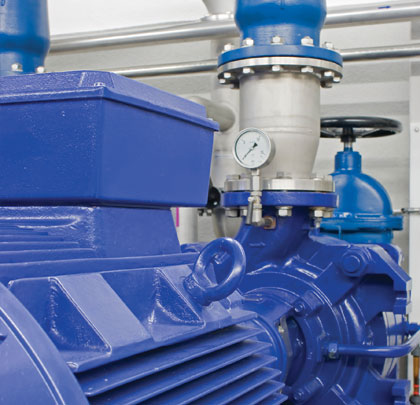

Many years ago, a Canadian consulting engineer was impressed by a well-designed API-style pump in a Visbreaker unit in Trinidad. He saw the merits of pure oil mist lubrication which, in this instance, benefited pumps that processed hot tar (bitumen) at 750 degrees Fahrenheit (~400 degrees Celsius). For many years, these pumps and their rolling element bearings ran safely, successfully, dependably, flawlessly, reliably. Later, in the early 1980s, this reliability-focused machinery engineer learned more about Pipestill Bottoms pumps with fluid temperatures of 740 degrees Fahrenheit (~393 degrees Celsius) at many U.S. oil refineries. Dozens of these high temperature process pumps were (and continue to be) lubricated by pure oil mist—again successfully, dependably, flawlessly.

Next, fast-forward to several specifications issued by less-informed reliability engineers in 2012. What’s particularly troubling is that some of these recent specifications were issued by the same world-scale oil refineries which, in the 1970s, had spearheaded successful implementation of plant-wide oil mist lubrication systems. With presumably no guidance from well-informed and more experienced professionals, one of these recent specifications now limits oil mist to pumps with pumping temperatures below 450 degrees Fahrenheit (232 degrees Celsius).

Even more astounding is a second one; it stipulates a 300 degrees Fahrenheit (149 degrees Celsius) pumpage cut-off for oil mist lubricated rolling element bearings. A few recent specifications also call for “heavy service factor reclassifiers,” although no such “heavy service factor” reclassifiers (oil mist flow orifices) were ever found necessary for process pumps in the forty years prior to 2013.

Limiting oil mist applications to pumping services not exceeding 300 or 450 degrees Fahrenheit begs an important question: What lube application method will best serve pumps with 600 and 740 degrees Fahrenheit operating temperatures? Other than the outstandingly well-proven and widely used pure oil mist, only liquid oil sprayed directly into a rolling element bearing’s cages is a suitable option for the reliability-focused. Reverting back to liquid oil sumps with oil rings and constant-level lubricators will have serious negative maintenance cost impact. And an even worse case scenario would exist with conventional lubrication and inadequate maintenance. In that instance, the equipment owners must brace themselves for adverse safety and reliability impact.

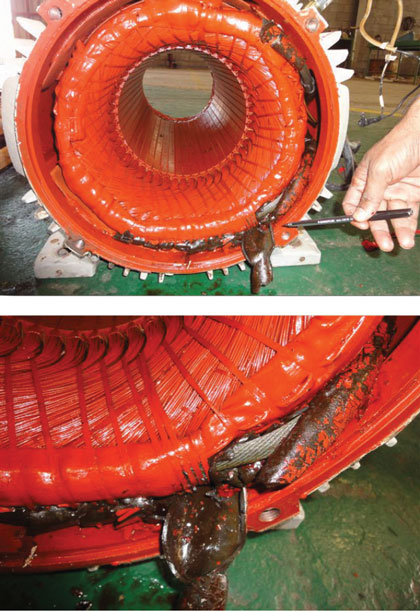

Swollen T-leads in an electric motor.

IMPLICATIONS OF CONTINUOUS PUMP OPERATION AT 25 PERCENT OF DESIGN-POINT FLOW

Another recent oil refinery specification requires all process centrifugal pumps to be continuously operable at 25 percent of the capacities shown on their respective design flow plans. If such clauses are enforced, the owner-operators could be locked into purchasing highly inefficient pumps or, so as to gain available net positive suction head, the owners will have to consider elevating pump suction vessels high into the sky.

Alternatively, the pumps might have to be provided with variable frequency drives, or automatic bypass valves, or whatever. It’s just another example that shows a surprising lack of technical understanding. The cure would be to read a few of Igor Karassik’s old pump texts or, as of 2013, to study twenty-nine years’ worth of Texas A&M’s International Pump User Symposium Proceedings. But simply tightening a specification will either have serious cost consequences up front, possible failure consequences later, or both.

DO THEY REALLY WANT FLEXIBLE DISC COUPLINGS FOR RECIPROCATING FLUID MACHINES?

In general, flexible disc couplings are mature and well proven for rotating fluid machines such as process pumps, mechanical drive steam turbines and dynamic and rotary screw positive displacement compression machinery. However, flexible disc couplings have torsional damping characteristics that are not well suited for reciprocating pumps and reciprocating compressors. Insisting on their use for reciprocating fluid machinery does not always make sense in view of the uniquely different damping requirements needed for certain types of reciprocating machines.

When a major reciprocating compressor manufacturer recently (and reluctantly) acceded to a specification calling for flexible disc couplings, failures and unplanned downtime events resulted. The compressor manufacturer had to honor certain warranty stipulations and lost both revenue and image. While it would serve little purpose to pinpoint blame for what occurred here, it is only fair to note that blanket specifications calling for a particular component style regardless of machine type are highly inappropriate. As a lubrication manager later remarked, size 48 pants will fit an entire population, but they will not be stylish. To which we might add that most folks will need hard-to-come-by suspenders to wear this size pants.

EXPERIENCE WITH OIL MIST ON ELECTRIC MOTORS

After noting swelling of the terminal wire insulation (“T-leads”) in relatively new electric motors, one operating company was understandably concerned. Swollen T-lead insulation at the motor’s stator ends can impede the flow of cooling air. Because the T-lead insulation on thousands of motors had not swelled in 40 years of use, pin-pointing the cause should not have been difficult: A prominent motor manufacturer had recently changed insulation materials on his motor T-leads. The manufacturer began using a material with a swell rate in excess of 10 percent at 50 degrees Celsius while the decades-old satisfactory precursor material had swell rates of only 1.8 percent at the same temperature. And of the motors equipped with the precursor materials, over 26,000 were commissioned in the decades leading up to 2010. In fact, about 1000 of these had been installed in Texas from 1975 through 1978 and lubricated with pure oil mist. Many were still operating flawlessly when we last checked with the user, in 2012. In other words, as of 2012, these motors had been in successful service for thirty-four years.

One of the roles mapped out for an informed owner-purchaser’s reliability engineers is to ask questions whenever equipment manufacturers change to “newer” materials. We know of employment rules dating back to 1965; staying informed on changes and understanding their potential impact on equipment safety and reliability was one of the machinery engineer’s roles at that time. Why should that role be any different today?

It gets worse. At one petrochemical plant (in 2012) the initial and incomprehensible response to T-lead swelling in motors was contemplating returning to grease lubrication. But grease lubrication needs to be done periodically and correctly. The maintenance intensity and training requirements for properly re-greasing electric motors exceed efforts devoted to lubricating with pure oil mist by a factor of 10. A professionally superior approach would have been to question the motor manufacturer and to fully understand why changes were made to a previously flawless insulating method. Cooperative motor manufacturers would readily assist with the analysis and would implement the right remedial action without delay. In this instance, T-leads coated with the well-proven low-swelling material should not have been abandoned in favor of “new” T-leads, ones with a much greater swell rate. And reverting to grease lubrication will rarely qualify as twenty-first century reliability engineering. Instead, insistence on T-leads that have served us well for thirty-four years would seem appropriate.

SPECIFY WITH FORETHOUGHT

These and other regressive case histories illustrate a mid-twentieth century, stuck-in-the past mind-set. Recognizing that brighter minds can be groomed should give leading companies opportunities to move further ahead of the ossified traditionalists. That said, a few twenty-first century operating companies are developing a questioning attitude. They demand fact-based answers from reliability engineers. The managers of these (relatively few) companies refuse to act on mere opinions and recognize that wild guesses are unproductive at best, and dangerous at worst.

There is light at the end of the tunnel. Occasionally, a leader emerges from the haze and fog of trial-and-error engineering. Best-of-class companies are aligning their specifications with best available practices. These companies manifest and practice leadership at all levels. True leadership is conduct which convinces others to accept a course of action which, although not initially perceived as beneficial by the tradition-bound, is ultimately of far-reaching benefit to a business entity.

Translation: Do some reading before you become a party to specifying counterproductive requirements. Speak up! It can be done tactfully, but must be done decisively and authoritatively. Make your contributions based on factual information. Join the trend set by smart specifiers who are pushing the envelope towards pursuing a twenty-first century mind-set. We commend them and recognize them as the true value-adders. ■

_________________________________________________________________________

ABOUT THE AUTHOR

Heinz P. Bloch, P.E., is one of the world’s most recognized experts in machine reliability and has served as a founding member of the board of the Texas A&M University’s International Pump Users’ Symposium. He is a Life Fellow of the ASME, in addition to having maintained his registration as a Professional Engineer in both New Jersey and Texas for several straight decades. As a consultant, Mr. Bloch is world-renowned and value-adding. He can be contacted at heinzpbloch@gmail.com.

_________________________________________________________________________

MODERN PUMPING TODAY, November 2013

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!

![]()