A natural gas development platform in the Gulf of Thailand, operated by Carigali-PTTEPI Operating Company Sdn. Bhd. (CPOC), has saved $52 million per year and significantly reduced water usage and chemical consumption with help from GE’s advanced cooling and chemical treatment technology. GE helped CPOC reduce its chemical consumption by 9.5 tons (8.6 tonnes) and decrease shutdown time and production loss.

REWARDING REDUCED WATER USE AND CHEMICAL CONSUMPTION

In honor of its notable reductions in water usage and chemical consumption, GE awarded CPOC an “Ecomaginaton Award,” which recognizes the achievements of industrial users for striking a positive balance between today’s environmental, industrial and sustainability challenges. It is given to the top GE customers in environmental and economic performance.

“Our Muda Field platform was losing a significant amount of money per year due to unplanned shutdowns. We needed an immediate solution and turned to GE for help. Now we are no longer faced with work stoppage and loss of production, and GE has saved us significantly in operating expenses, water and chemical usage,” says Shahzada M. Nisar, head of operation, Carigali-PTTEPI Operating Company Sdn. Bhd.

INCREASING UPTIME

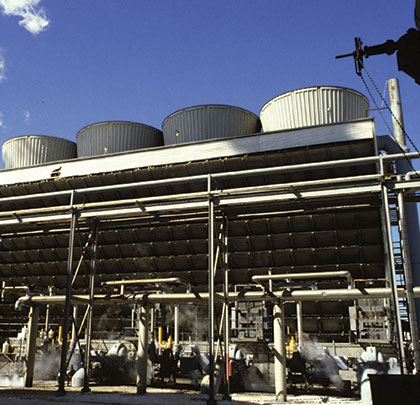

CPOC’s platform in the Muda Field is located approximately 93.2 miles (150 kilometers) northeast of Kota Bharu in Malaysia, 155.3 miles (250 kilometers) east of the Songkhla province in Thailand and 217.5 miles (350 kilometers) north of the Kemaman Supply Base in water with depths ranging between 180.4 and 213.3 feet (55 and 65 meters). It had been using a cooling medium to cool off gas from compressors for gas processing and gas export, but the system failed to run as designed and was being shut down frequently for cleaning to maintain safe operation and sustainable production.

On average the facility was shut down for six unplanned days per year for cleaning, causing CPOC a production loss of approximately $52.2 million. CPOC’s gas processing platform has the ability to produce 369 million square feet (34.2 million square meters) per day and the capacity to generate gross production worth $8.7 million per day.

To ensure the system would run smoothly, CPOC called on GE for situational mapping, an investigation of the cooling system and for a chemical treatment change out and make-up water quality improvement. GE also was able to conduct enhanced monitoring and service support for CPOC’s natural gas development platform.

EXPERTS IN THEIR FIELD

GE is a leader in the oil and gas, refining and hydrocarbon processing industries, helping to minimize corrosion, reduce fouling, save energy, reuse water and minimize down time. GE also provided CPOC with a neutral pH cleaning and integrated water treatment program at the boaster, gas compressor printed circuit heat exchanger and cooling medium loop.

“Oil and gas producers have unique water management needs, especially in remote locations. GE’s vast expertise and experience in this industry enabled our team to provide Carigali-PTTEPI Operating Company proven solutions to enhance its system reliability and increase production at its platform in the Gulf of Thailand,” says Hoshang Subawalla, APAC regional executive of water and process technologies for GE Power and Water.

UNLOCKING WATER’S POTENTIAL

GE and the Wharton School of the University of Pennsylvania recently hosted “The Economic Power of Water” event, where they announced this platform before an audience of both public and private organizations, as well as thought leaders in water policy and research. The event brought together these professionals to explore the current challenges to unlocking the economic potential of water and to provide actionable next steps to create a more water- and energy-secure world. ◆

GE Power & Water’s Zainudin Mustaffa can be reached at zainudin.mustaffa@ge.com. GE Power & Water provides customers with a broad array of power generation, energy delivery and water process technologies to solve their challenges locally. Power & Water’s six business units include Distributed Power, Nuclear Energy, Power Generation Products, Power Generation Services, Renewable Energy and Water & Process Technologies. Headquartered in Schenectady, New York, Power & Water is GE’s largest industrial business.

____________________________________________

MODERN PUMPING TODAY, July 2015

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!

![]()