VAL-MATIC

Tilted Disc Check Valve

The Val-Matic Tilted Disc® Check Valve offers unbeatable versatility and reliability while delivering substantial cost savings over the life of the valve. The valve’s 40-degree disc stroke and 20-degree seating angle provides quick closure, drop tight seating, and reduction in water hammer. The Tilted Disc® Check Valve uses energy efficient operation, streamlined body contouring, and a flow area 40 percent greater than nominal pipe size to deliver the lowest headloss of any check valve produced today! Top or bottom mounted oil dashpots can be added for systems with extreme conditions such as high shut-off heads, surge tanks or multiple pump applications. These features and benefits combine to make the Tilted Disc® Check Valve an ideal choice for a wide range of applications including raw water, cooling water and treated water/wastewater applications. The Tilted Disc® Check Valve is offered in 125B, 150B, and 250B AWWA Classes in sizes 4 to 60 inches for pressure ranges up to 400 PSI. The valve is NSF/ASNI 61 certified for drinking water and NSF/ANSI 372 Certified Lead-Free. For more information regarding the Val-Matic Tilted Disc® Check Valve, contact Kara Vojak, marketing coordinator, at 630. 993.4023, email kkv@valmatic.com, or visit www.valmatic.com.

COLLINS INSTRUMENT COMPANY

Model 2060 Control Valve

A low-cost 2-inch flanged plastic control valve, designed to handle corrosive fluids, is now available from Collins Instrument Company, Inc. of Angleton, Texas. The Model 2060 is the latest addition to the Collins family of plastic valves. The 2060 features a body of either PVDF or polypropylene and an actuator/yoke of glass-filled polypropylene, making it suitable for harsh fluids and/or corrosive environments. Depending on the application, the 2060 can be equipped with either a pneumatic positioner, a positioner with integral I/P, or an electric actuator. The 2060 is available with trim sizes up to Cv = 38, features either all-plastic trim, all-metal trim, or a combination of exotic alloy metal/plastic trim for special applications, and can be supplied with various optional features. For more information on the Model 2060, contact Collins Instrument Company, Inc. by calling 979.849.8266, emailing cic@collinsinst.com, or visiting www.collinsinst.com.

R+W AMERICA

Survivor Series Couplings

With the introduction of its new Survivor series couplings, R+W Coupling Technology is offering a more robust alternative for API 610 pump packages. API 610 is a set of standards that are written and regulated by the American Petroleum Institute to ensure that reliability and safety standards are upheld in what can be a dangerous industry. Very specific guidelines also cover the design and installation of flexible shaft couplings. The key differentiating advantage of the LPA is that R+W Survivor series couplings transmit torque across the disc pack assemblies purely by friction. A series of bushings are pressed together by R+W to assemble the disc packs, while precision locating features in the hubs and spacers present a concentric fit. For more information, visit www.rw-america.com.

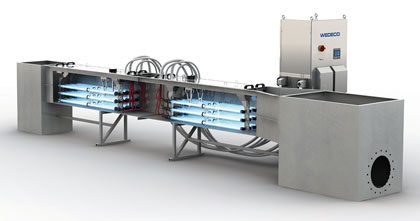

WEDECO, A XYLEM BRAND

TAK Smart UV System

The WEDECO TAK Smart UV system makes the disinfection of wastewater flows as easy and cost-effective as possible, without any compromise in quality or flexibility. Similar to its big brother the TAK 55, TAK Smart systems feature the same UV lamp and configuration, with a set of common equipment options. Fully preassembled, the TAK Smart is available in ten sizes and can be customized with different types of channel material, single or double UV bank arrangement, an optional automatic wiping system, various cabinet designs as well as robust UV monitoring and control features. Equipped with WEDECO’s latest ECORAY® high intensity low pressure (Hi-Lo) UV lamps and ballasts, the system provides reliable performance while minimizing energy consumption. It even meets the most stringent validation requirements as outlined in the US EPA UVDGM 2006. Altogether, the TAK 55 Smart is the perfect fit for small effluents of varying wastewater qualities: from sewer overflows to tertiary wastewater reclamation. For more information, visit www.xyleminc.com.

HAYWARD

T-Series Thermoplastic Pumps

Hayward Flow Control announces the release of our new T-Series thermoplastic pumps. This new line of vertical seal-less immersible pumps compliments our industry leading line of pumps. The pump features a single, non-coupled motor/impeller shaft with a proprietary patent-pending shaft seal. The T-Series Pump is available from 1/3 HP to 1-1/2 HP with standard and wash-down motors and in voltages of 115/230 and 208-230/460. Additional options include GFPP or PVDF pump head and impeller assembly, inlet screen, in-tank filtration, impeller trim variations, explosion-proof motors, 575V motors and S-J type electrical cord. Typical applications or installations include but are not limited to chemical processing and transfer, metal plating, waste and water treatment, mining, aquatic and animal life support systems, and electronics. For more information, contact Hayward Flow Control at 888.429.4635, email hflow@haywardnet.com, or visit www.haywardflowcontrol.com.

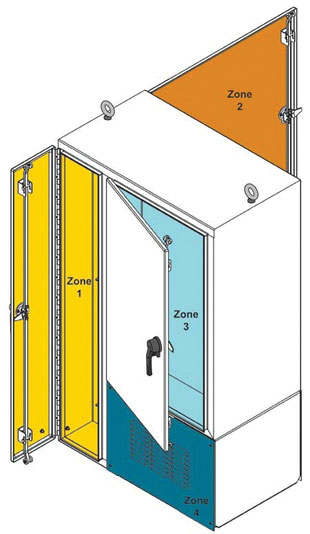

SJE-RHOMBUS

Wall Mount Arc Armor Municipal Lift Station Pump Control Panel Enclosure

SJE-Rhombus and its engineered control panel companies now offer a wall mount enclosure and additional enclosure sizes for the innovative, multiple compartment Arc Armor® pump control panel enclosure. This enclosure reduces the risk of injury resulting from arc flash and electric shock. The control and power circuitry are isolated in separate compartments, preventing unnecessary exposure to arc flash or arc blast by municipal system operators. The Arc Armor® enclosures are suitable for a wide range of pump applications. To learn more about this enclosure, visit www.ecosmartpanel.com or SJE-Rhombus at 888.342.5753 or www.sjerhombus.com.

_________________________________________________________________________

MODERN PUMPING TODAY, July 2013

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!

![]()