As more and more industries are relying on renewable energy sources for their needs, Finish Thompson is using its expertise in the corrosive chemical transfer industry to drive innovation in clean energy with its DB Series mag-drive pumps. These advanced pumps are playing a pivotal role in the offshore wind industry, supporting the national push toward renewable energy with their efficient, reliable, and maintenance-saving designs. As wind power becomes central to the clean energy movement, Finish Thompson’s DB Series is proving to be indispensable for offshore wind turbine applications.

MEET THE DB SERIES

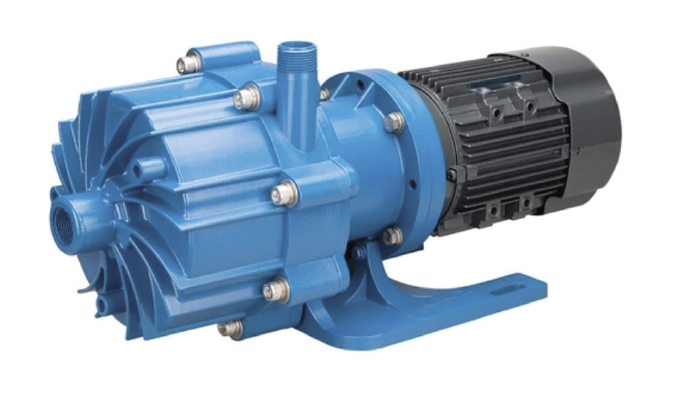

The DB Series pumps are designed with neodymium magnets, allowing for a compact design that saves space, complete with a replaceable shaft and bushing that reduces repair costs. The pumps are ISO 1940 G2.5 balanced, ensuring smooth operation with virtually no vibration, which makes them ideal for the demanding conditions of offshore wind farms. Additionally, the DB Series mounts to NEMA and IEC motor frames, allowing it to be used globally, while the back pullout design simplifies maintenance and reduces downtime. The pumps feature a close-coupled design for a compact package and are equipped with a five-year warranty, providing peace of mind to operators.

SUPERIOR DESIGN, SUPERIOR RELIABILITY

One of the most significant advantages of the DB Series is its sealless mag-drive design, which eliminates the primary cause of pump failure—the mechanical seal. This not only improves reliability but also enhances safety by preventing the pumped liquid from leaking, a crucial benefit for offshore wind turbines where environmental protection and operational continuity are paramount. Equipped with a carbon bushing, the pump’s ability to run dry for hours without damage prevents further damage from operator error or system issues.

Additionally, its corrosion-resistant polypropylene or PVDF construction ensures it can handle a wide range of fluids, including those found in wind turbine applications. This high-efficiency pump reduces power consumption, further lowering the total cost of ownership by using less electricity.

THE FUTURE IS NOW

The DB Series has demonstrated immense value in real-world offshore wind farm applications. A growing number of renewable energy applications show how these sealless mag-drive pumps deliver critical resources for renewable energy systems, reducing maintenance costs and ensuring continuous operation in remote areas.

As the United States accelerates its clean energy initiatives, wind power is expected to play a significant role in the country’s energy future. Offshore wind farms are seeing substantial growth, with numerous projects underway along the nation’s coastlines. Finish Thompson’s DB pumps are well-positioned to support this expansion by providing reliable, efficient, and low-maintenance solutions for wind turbine operations.

THE STANDARD FOR HYDRAULIC EFFICIENCY AND CORROSIVE FLUID HANDLING

- Sealless mag-drive design

- Engineered for performance and proven in the field

- Runs dry for hours without damage when equipped with a carbon bushing

- Best efficiency of any pump in its class

- Polypropylene or PVDF corrosion resistant construction

- No seal replacement and no leaks

- Horizontal or vertical installation (with IEC motor only)

- High specific gravity handling—over 1.8s

Casey Bowes is the owner/CEO of Finish Thompson, Inc.. in Erie, Pennsylvania. Finish Thompson Inc. designs and manufactures pumps for the safe transfer of a wide variety of corrosive fluids. Products include sealless mag-drive centrifugal pumps with run-dry capability, mechanically sealed pumps, drum/barrel pumps, vertical mag-drive pumps, multi-stage pumps and the FTI Air line of air operated double diaphragm (AODD) pumps. For more information, visit www.finishthompson.com.