While water well drilling and pump installation contractors have access to products at local hardware stores, big box stores, or regional wholesalers, they are often exposed to a fraction of what is actually available. Retailers, in fact, typically offer only a few of the most common items. Even wholesalers tend to funnel contractors to the products that they stock.

ADDRESSING TODAY’S CHALLENGES

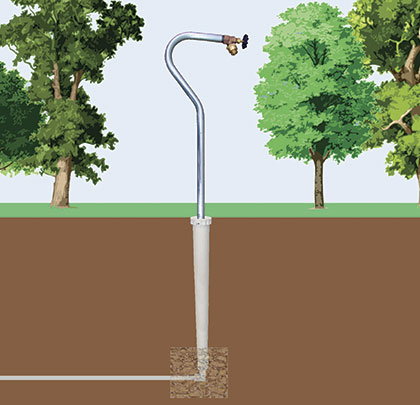

The complexity in a domestic water well system begins with the myriad parts needed to integrate the well, pump, water storage tank, all the pipes and fittings, and the water distribution line to where it is utilized. Adding to the challenge are the various codes and design options required to meet tougher federal, state, and municipal regulations.

Increasingly, the “standard” list of core stock items is no longer enough to meet such demands. As a consequence, having the right parts and accessories for the job requires a source that offers a wide range of options and code-compliant choices.

VARIETY EQUALS EFFICIENCY

Now a growing number of contractors are demanding suppliers readily offer a more comprehensive list of parts and accessories that enable the streamlining of installations and maintenance, allowing contractors to take on more jobs.

“As proactive contractors look beyond the usual parts and accessories, they are finding attractive options they never knew existed,” says Danny Ahrens, owner of Florida-based Water Products Marketing, a supplier of water well equipment to distributors and contractors. “Innovation is helping them to install water well equipment more efficiently and cost-effectively while at the same time improving quality; and that gives them an edge in the market.”

GAINING AN EDGE

While some contractors tend to use the same standard parts and accessories that perhaps their mentors or fathers did, too often this approach can become a rut that limits their work efficiency and business success. Finding and trying more effective non-standard parts can dramatically cut their installation times, among other benefits, if they ask their distributors and wholesalers for a wider range of options.

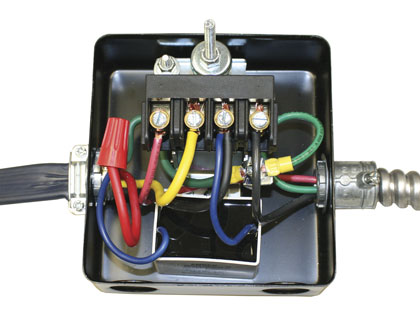

As an example, as opposed to installing a traditional control box and pressure switch, running wires between them, and fitting all the connections in an undersized case, contractors could be using a Control Switch. This innovative device combines a three-wire control box (with start capacitor, relay, run capacitor, and a wire terminal strip) and a pressure switch into one easier to install device. The design eliminates the added time to install and connect a pressure switch and a separate control box.

The device, by Merrill Manufacturing, an Iowa-based water well/water system accessory manufacturer for the domestic, residential market, offers a heavy-duty pressure switch for longer life, an extra-large case for easy wiring, and heavy brass wire connections that can hold #4 wire.

“Instead of a standard pressure switch and control box, installers are finding that Merrill’s control switch can act like a junction box,” says Ahrens, who has been involved with more than fifty field installations with the device, some operating more than nine years.

“The design reduces the amount of required connections—including conduit, fittings, washers, and lock washers—by half,” explains Ahrens. This speeds installation up to 50 percent, allowing installers to take on more jobs. It also extends service life, minimizes time-wasting nuisance calls, and eliminates issues related to start capacitors and relays.”

Because the control switch works universally with all brands of motors, it also reduces the inventory of replacement parts that contractors must bring to the jobsite. “Traditional control boxes are motor specific, so have to be matched to run properly,” says Ahrens. “With the control switch, however, contractors can travel light because it works with any domestic or foreign motor.”

A LOOK AHEAD

In next month’s conclusion, we’ll go deeper into the details of a typical installation and discuss some of the options that contractors will need to consider to find the right fit for their project. ◆

For More Information:

Stephen Anderson is the president of Merrill Manufacturing and serves on various advisory boards and committees. Merrill Manufacturing manufactures and sells the industry’s largest selection of water well accessories and maintains membership in the Water Systems Council, National Ground Water Association, Water Well Trust, and numerous state water well associations. For more information, call 800.831.6962 or visit www.merrillmfg.com.

____________________________________________

MODERN PUMPING TODAY, September 2016

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!

![]()