Hydrogen use is growing rapidly worldwide to provide a clean source of energy in a variety of industrial applications, but until now the residential market has had limited use. This situation is changing as utility companies worldwide are exploring delivery solutions to enable their customers to use hydrogen for emission reduction.

For example, Southern California Gas (SoCalGas), a regulated subsidiary of Sempra Energy, is working with Emerson to deploy digital technologies, software, and services to demonstrate the resiliency and reliability of a hydrogen microgrid for southern California utility consumers.

The [H2] Innovation Experience is one of the first projects of its kind in the United States, and it shows how this carbon-free gas made using renewable electricity can be consumed in pure form, or blended with natural gas to fuel clean energy systems of the future. Now operating, this demonstration project provides a path to reducing emissions from home energy use—another critical contribution to a cleaner energy future.

EMISSIONS ARE THE ISSUE

Current electric and natural gas production and distribution systems provide a reliable source of low-cost energy to billions of residential customers worldwide, but more effective and efficient appliance designs can reduce emissions at use points.

Electricity is typically generated by large plants and facilities, and then distributed to residential customers. This system works well in terms of reliability and cost, but limitations arise due to a variety of factors. Fossil-fueled generation results in emissions, and there are limits regarding how much power can be produced by hydro, geothermal, nuclear, and other low- or zero-carbon energy sources. Solar and wind power are an alternative in some locales, and stored hydrogen can smooth out the intermittent nature of output from these sources.

Natural gas is the cleanest-burning of all the fossil fuels, largely because of its high hydrogen content of four hydrogen atoms for each carbon atom. It is by far the lowest cost and most plentiful source of energy for many residential applications, including space heating, water heating, drying laundry, and cooking.

Alternative sources of energy, primarily electricity, are much more expensive for these types of residential applications, rendering them impractical for many. And, has been shown in many natural disasters, the natural gas distribution system is much more resilient than the electrical distribution system, largely because it is underground, and thus protected to a large extent from storm damage.

But despite these advantages, even the most modern natural-gas-fueled appliances produce some level of carbon dioxide emissions. The [H2] Innovation Experience addresses this and other issues by reducing emissions and providing other benefits.

CLEANER ENERGY GENERATION AND USE

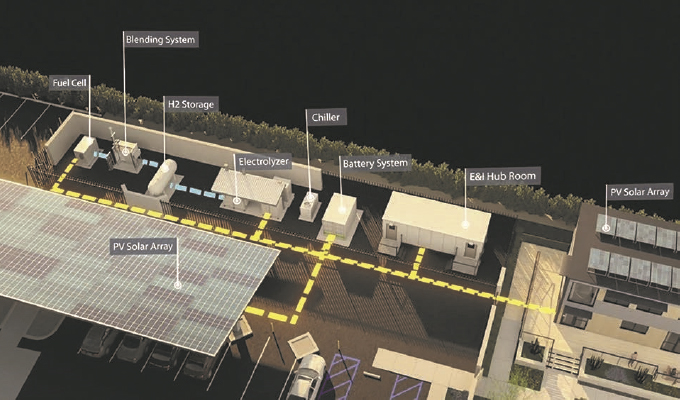

SoCalGas commissioned its project [H2] Innovation Experience to provide a working example of what tomorrow’s residential energy system could look like (see figure 1). The nearly 2,000 square-foot home is outfitted with solar panels, a power storage battery bank, an electrolyzer to convert solar energy to renewable hydrogen, and a fuel cell to supply electricity. Hydrogen, produced at the site, can also be blended with utility-provided natural gas and used in the home’s heat pump HVAC unit, water heater, clothes dryer, and stove.

Gas flow and precise gas concentrations are monitored and controlled with control hardware, instrumentation, and software provided by Emerson and integrated by Caltrol Inc., an Emerson Impact Partner. The [H2] Innovation Experience is effectively a small-scale microgrid, able to reliably deliver power in multiple forms when energy is needed. Such installations can provide long-duration energy storage, along with low-carbon distributed power. When constructed on a larger scale, this type of system could provide clean energy to residential neighborhoods and businesses.

The Emerson- and Caltrol-designed control system balances energy supply and demand within the home, and the system contributes energy to the local grid when possible, either as electrical power or by blending hydrogen into the natural gas distribution system, all with zero-carbon emissions.

IMPLEMENTATION DETAILS

In addition to deep domain expertise in hydrogen, Emerson delivered advanced process control systems to SoCalGas, as well as:

- Safety instrumented systems

- Electronic marshalling technology

- Instrumentation

- Final control elements

- Analytics solutions

These work together to help meet the utility’s environmental, social, and governance goals—as well as safety requirements.

The [H2] Innovation Experience is powered entirely by electricity generated by a photovoltaic array. During a sunny day, immediate power requirements are provided by the array, plus it has additional capacity to charge a large stationary battery and/or feed power into an electrolyzer to manufacture green hydrogen.

This arrangement offers multiple energy supply and consumption options:

- The residence can store compressed hydrogen, and feed it into appliances (e.g., water heater, clothes dryer, etc.), modified to burn pure hydrogen, or blend it with natural gas for use with standard appliances.

- If electric power is needed in excess of what the array can provide, at night for example, it can be drawn from the battery, or stored hydrogen can be fed into a fuel cell to create electric power. A fuel cell creates heat as well as electric current, so maximum efficiency occurs when the heat is used for hot water or warming the residence.

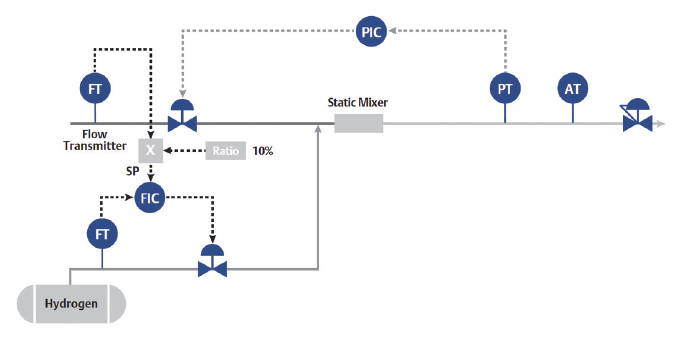

Operating an electrolyzer and internal blending station requires an appropriate level of control to follow consumption closely, requiring flow control across a high turndown range. Depending on the number of natural gas consuming applications in use at any given time, the amount of hydrogen added may be at maximum or turned down to virtually zero. Maintaining a consistent hydrogen feed rate requires, minimally, monitoring the natural gas feed flow and pressure so the blending system can calculate the maximum addition rate.

An analyzer must be used to determine the actual composition after mixing. Unfortunately, relevant analyzer technologies may be fast by analyzer standards, but are slow compared to a flow meter, and the lag time is too long for controlling a loop if loading changes frequently. For example, this can happen if a large appliance consuming a significant proportion of the total flow starts or stops, as with a clothes dryer.

A more sophisticated approach (see figure 3) is used in this case for monitoring the flow of both natural gas and hydrogen to determine the appropriate ratio, with an analyzer (Figure 4) verifying the mix. This approach is especially critical if gas supplied to the residence already has hydrogen blended with it from other sources upstream.

This arrangement requires multiple flow meters, pressure transmitters, control valves, and an analyzer, all supported by an automated control system. It reads the process variables, makes all necessary calculations, and adjusts various valves to ensure a desired mixture, confirmed by the analyzer. It must have the ability to adjust quickly to load changes, even where they can be unpredictable and abrupt.

The control system reliably performs all these functions and more, providing a high degree of efficiency for the entire system.

CONCLUSION

These types of residential and small neighborhood-scale facilities, like the [H2] Innovation Experience, can generate, store, and transmit electricity with zero carbon emissions, and will thus be a critical component for meeting sustainable power demand. Emerson equipment and Caltrol know-how facilitated a shorter startup, while ensuring the safety and reliability of the systems necessary to make this approach practical.

Balancing energy consumption optimally with existing sources requires sophisticated control and precise measurement. Emerson has provided automation solutions and expertise on a wide variety of hydrogen projects globally, often working with its Impact Partners near the sites, as it did with SoCalGas and Caltrol on this project. The potential for hydrogen to make power distribution more sustainable is enormous and shows how the utility industry, and individual consumers, could benefit from it as a practical means of change.

While just a single home, this project shows what’s possible, and its solutions can be implemented all at once for new construction, or they can be retrofitted one at a time for existing residences. Either approach empowers consumers to play their part in reducing emissions, following the actions of many industrial and commercial plants and facilities worldwide.

FOR MORE INFORMATION

Brian Burkowsky is a hydrogen strategy specialist for Emerson. Emerson is a global technology and software company providing innovative solutions for the world’s most essential industries. Emerson is an automation leader that helps process, hybrid, and discrete manufacturers optimize operations, protect personnel, reduce emissions, and achieve their sustainability goals through its unmatched automation portfolio. For more information, visit www.emerson.com.

MODERN PUMPING TODAY, December 2022

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!