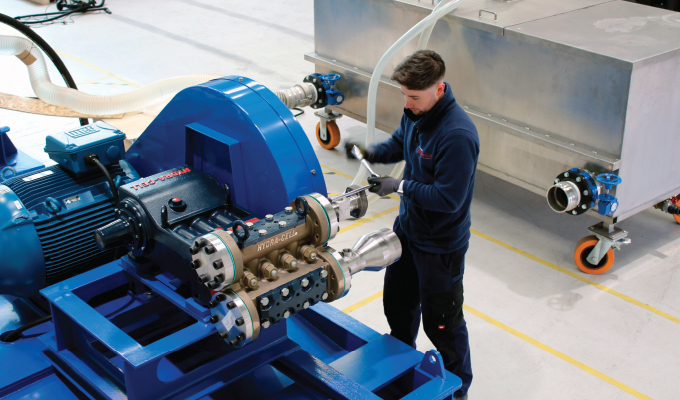

Wanner International’s new Technical Center of Excellence in industrial pump development formally opens today. The purpose-built facility enables the U.K.-based Wanner International operation to deliver enhanced service capabilities which include:

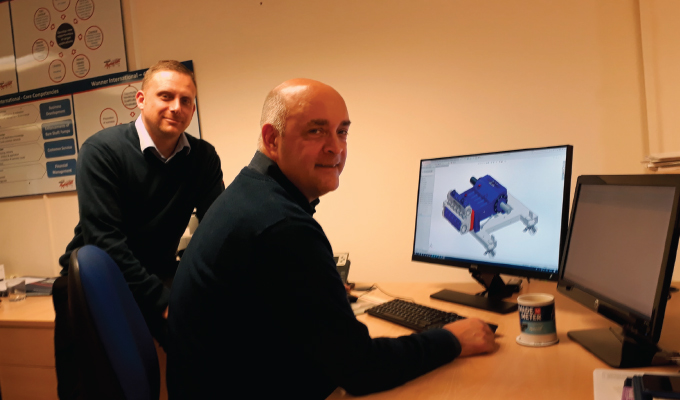

System design and custom pump builds

- Performance testing

- On-line and on-site witness testing

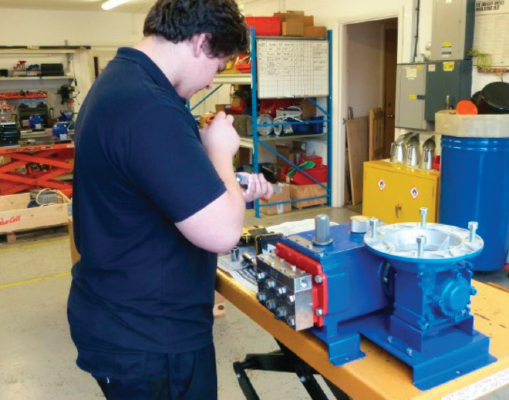

- Service and maintenance training

- Technology demonstrations

The company has invested in this 5,000-square-foot facility to increase capacity to meet the growing global demand for its services, to take its Hydra-Cell® pump onto the next level of technical innovation. This innovation is a must-have, not a luxury, as the current environment is changing rapidly, with new regulations on sustainability, customers demanding ever greater levels of effectiveness and more chemically challenging liquids to be moved efficiently.

The center will further strengthen the company’s support to its customers and partners in Europe, India, Middle East, Australia, Africa, Russia, and surrounding countries including Kazakhstan, Ukraine, and Azerbaijan.

STABILITY AND INNOVATION

Wanner is leading the way as one of the most progressive manufacturers in the process pump sector. Not only this, but in turbulent times of late, the company places huge emphasis on how this new development helps to both protect and create valuable new jobs.

As well as the main high volume manufacturing plant in the United States, this purpose-built facility enables the company to build small volume customized pumps, pump skids (a set including a driver such as an electric motor or diesel engine mounted on a common steel base), testing to meet customer specifications as well as hosting training workshops—either on-site or via online video.

Wanner enables their customers to run far more environmentally sound pumping processes as part of their overall operations. Hydra-Cell pumps are not only highly energy-efficient but the seal-less design (no dynamic seals) ensures 100 percent leak-free operation when dealing with toxic liquids. This means that unwanted emissions are eliminated from the process as well as protecting the health and safety of engineers and operators.

TECHNICAL AND ECONOMIC BENEFITS

The Technical Center of Excellence is improving both the economic benefit to the customer and reduction of their environmental impact by focusing on developing best-in-class across key capabilities such as custom design, research, training, and testing capabilities. The ultimate goal of boosting Wanner’s capabilities is to enable its customers to deliver both economically sound pump operations and ambitious environmental targets.

Paul Davis, Wanner International’s managing director, says, “We are very pleased to have seen growth in sales, considering the tough eighteen months we have all experienced. It is great to know that the additional advantages of the Hydra-Cell seal-less pumps over many other pump technologies have made a real difference in improving the processes of our oil and gas customers and other industries.

“In addition, the pumps’ unique features create real benefits as the industry faces increased challenges to protect the environment. With hundreds of thousands of pumps in service, the Wanner International team and its global partners have worked incredibly hard, especially through the pandemic crisis, to continue offering support and solutions to existing clients, whether that be via our online technical support or just having a real human being on the other end of the phone.”

HYDRA-CELL ADVANTAGES

The Hydra-Cell range are highly efficient, heavy-duty pumps for reliable liquid transfer, metering and dosing, injection, and spraying of a wide range of liquids and because of its seal-less design this can include corrosive, abrasive, and non-lubricating liquids. The pumps also have the ability to run dry indefinitely, without damage.

Elimination of seals and packing along with energy efficiencies of greater than 90 percent deliver a lower cost of ownership only possible due to the seal-less design of the Hydra-Cell range; some Wanner Hydra-Cell pumps have been reported to be in operation for over twenty years of service. This reduces unplanned downtime as well as cost savings on maintenance, spare parts and labor which has been a significant factor in reducing costs for customers in critical process manufacturing.

Davis continues, “We are very proud of our pump technology; we are proud of our people, from application support engineers, customer service staff through to our network of distributors which provide local support quickly and efficiently. So, in opening our new center of excellence we hope to be able to further enhance both the technology and service capabilities we have to offer.

“Continuing to invest strongly in R&D is how we have been able to expand across the globe and attract our specialist technical and sales partners who assist our clients across over seventy different countries. We look forward to the continued upward trend in growth and how the Hydra-Cell family continues to expand.”

FOR MORE INFORMATION

Wanner International prides itself in supporting customers, personally. With many years of pump and application experience, there is extensive knowledge available in the Wanner technical pump engineers and support network here to help customers at the end of the phone, no matter where they are in the world. For more information, visit www.hydra-cell.co.uk/our-capabilities/technical-centre-of-excellence.

MODERN PUMPING TODAY, December 2021

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!